Water-soluble soybean polysaccharides and manufacturing process therefor

A polysaccharide, water-soluble technology, applied in the field of water-soluble soybean polysaccharides, can solve the problems of unsuitability for long-term storage, no emulsion stability, low emulsion stability, etc., to reduce the emulsion particle size and widen the blending range. , the effect of low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

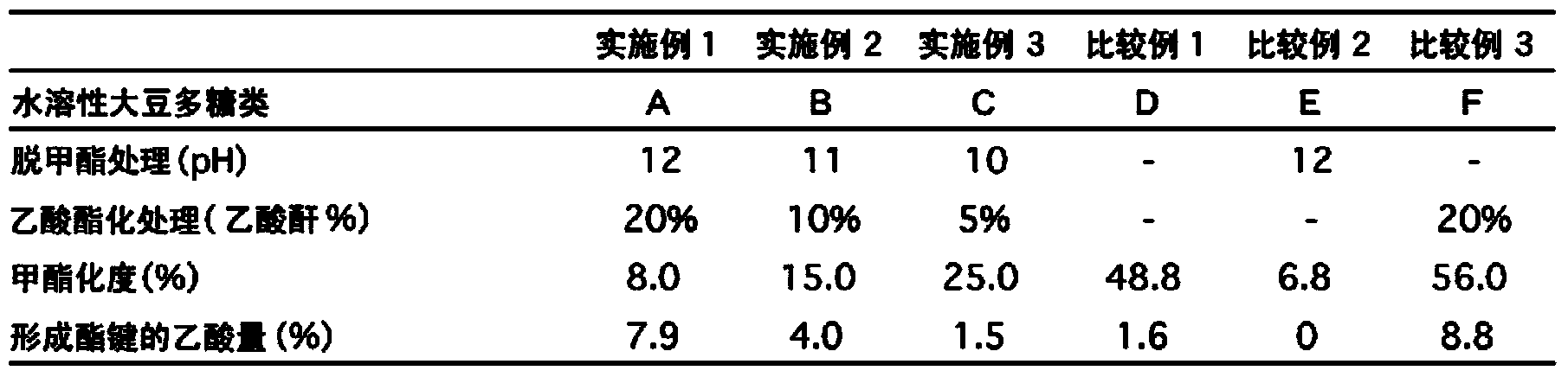

[0077] (Example 1) - demethylation treatment (pH12), acetic esterification treatment (20%) -

[0078] Using okara produced during the production of isolated soybean protein as a raw material, add water to it, and adjust the pH to 5 with hydrochloric acid. Then, the water-soluble soybean polysaccharides were extracted by heating at 125° C. for 2 hours in an autoclave. After the extraction, centrifugation (5,000×g, 10 minutes) was performed to separate into a supernatant mainly containing water-soluble soybean polysaccharides and a precipitate. Sodium hydroxide was added to the supernatant to adjust the pH to 12. Then, it heated at 60 degreeC for 60 minutes, and performed demethylation process. The precipitate produced by heating was removed, and the pH was adjusted to 5.0 with hydrochloric acid to remove the precipitate. Thereafter, desalination treatment was performed by electrodialysis, the aqueous solution of water-soluble soybean polysaccharides was concentrated to 10Bx,...

Embodiment 2)

[0080] (Example 2) - demethylation treatment (pH11), acetic esterification treatment (10%) -

[0081] In the same manner as in Example 1, water-soluble soybean polysaccharides were extracted, demethylated and acetic esterified. Here, the demethylation treatment adjusted the pH to 11, and the acetic acid esterification treatment used 10% by weight of acetic anhydride relative to the solid content. The obtained "water-soluble soybean polysaccharide B" was analyzed similarly to Example 1.

Embodiment 3)

[0082] (Example 3) - demethylation treatment (pH10), acetic esterification treatment (5%) -

[0083] Water-soluble soybean polysaccharides were extracted in the same manner as in Example 1, and subjected to demethylation treatment and acetic esterification treatment. Here, the demethylation treatment made pH 10, and the acetic anhydride treatment used 5% by weight of acetic anhydride relative to the solid content. The obtained "water-soluble soybean polysaccharide C" was analyzed similarly to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com