Organic light-emitting device and manufacture method thereof

A technology of electroluminescent devices and organic light-emitting layers, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, electrical components, etc., and can solve problems such as cost of mold opening, unfavorable product diversification, and high requirements for vacuum evaporation equipment , to achieve the effect of saving manufacturing and simplifying equipment construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

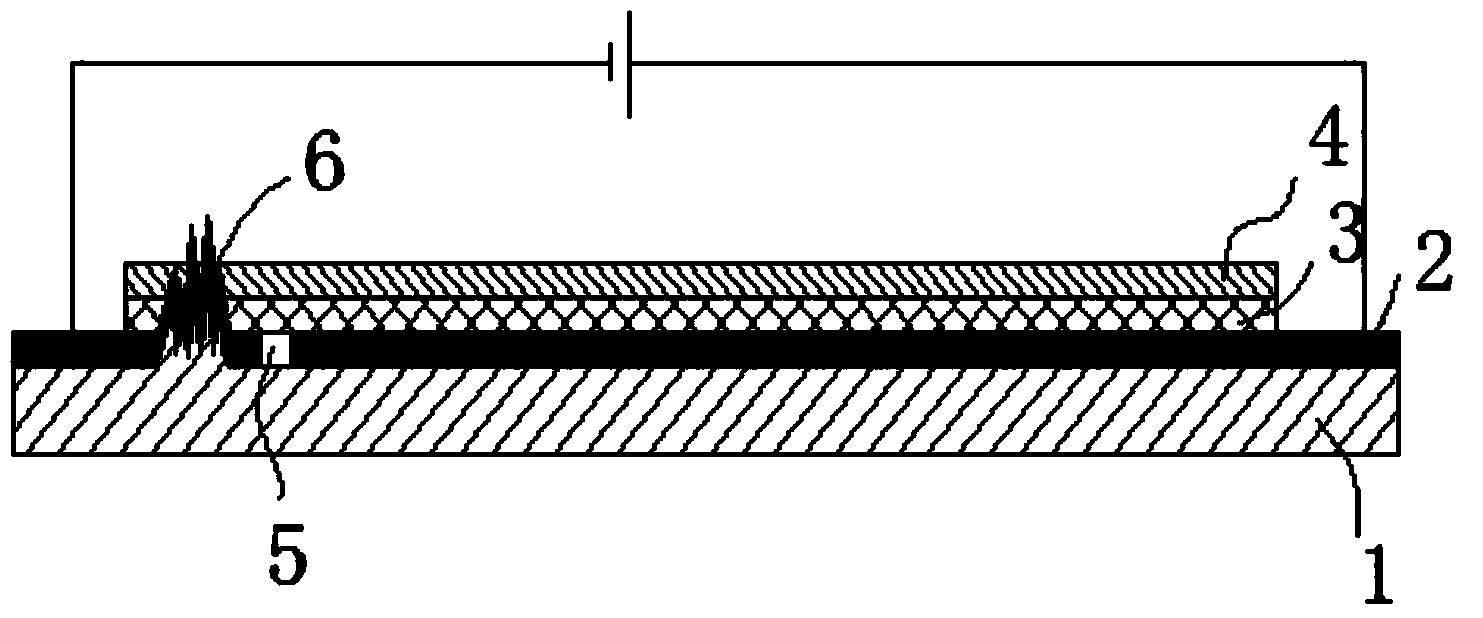

[0019] like figure 1 As shown, the organic electroluminescent OLED device of the present invention includes a glass substrate (1), a transparent conductive film (2), an organic light-emitting layer (3) and a metal electrode layer (4) from bottom to top. The glass substrate (1) contains a rough area (6), and the metal electrode layer (4) passes through the organic light-emitting layer (3) and the transparent conductive film (2) under the organic light-emitting layer (3) in the rough area (6) connect.

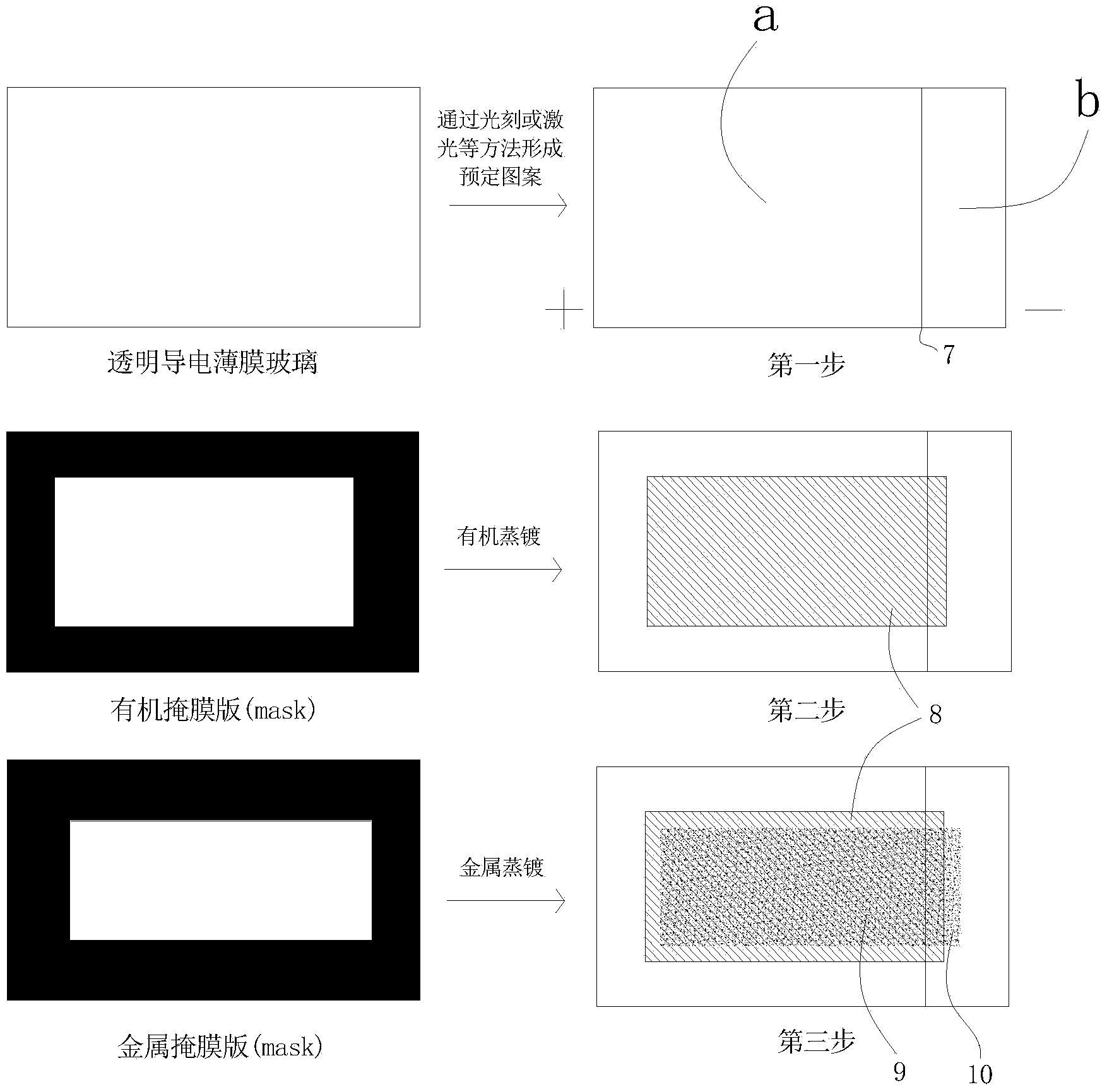

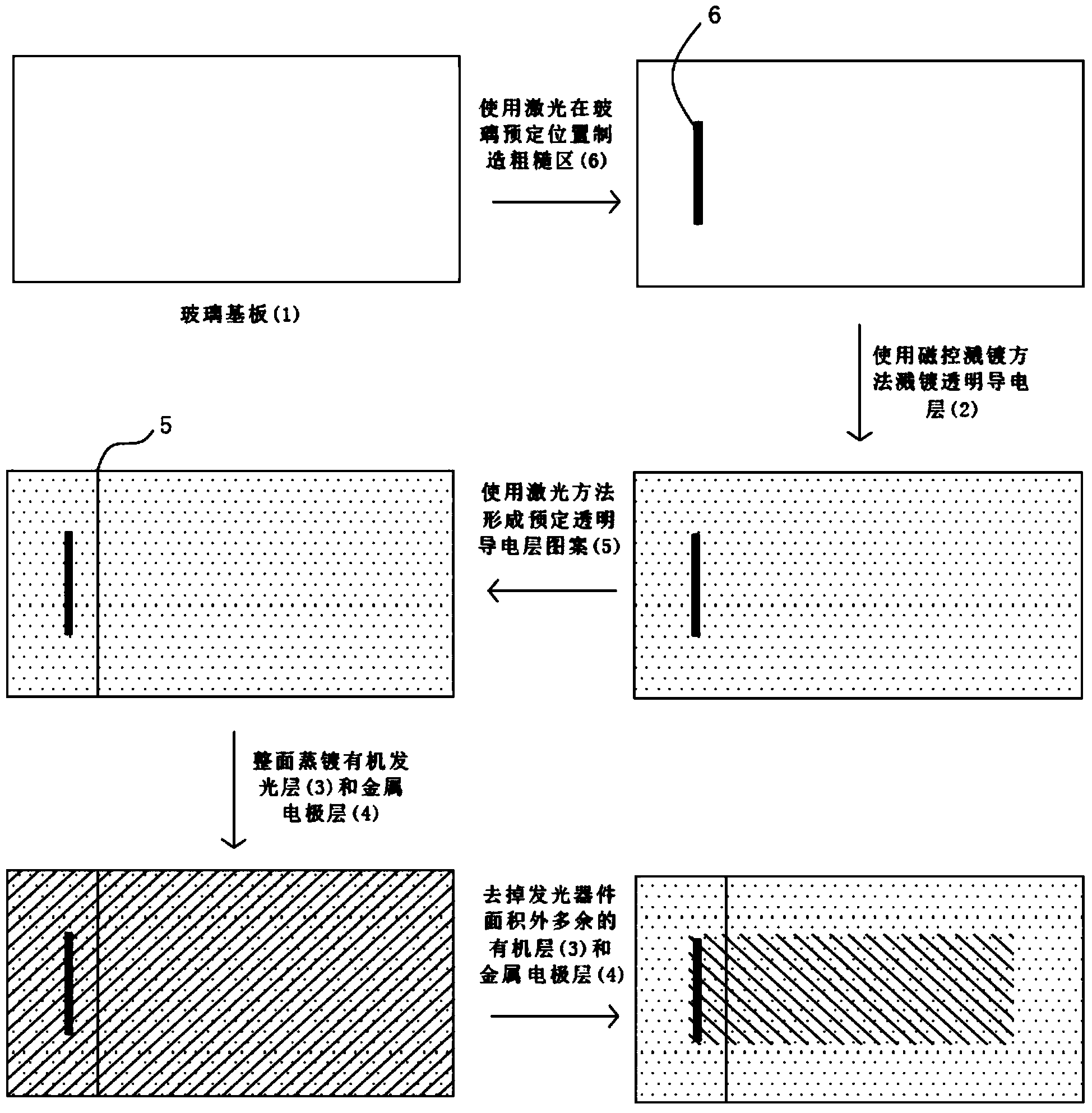

[0020] like image 3 Shown, the manufacturing method of organic electroluminescent device of the present invention, comprises the steps:

[0021] 1) Use a laser to carve a rough area (6) on the predetermined position of the plain glass substrate (1). The rough area (6) can also be formed by coating rough substances on the surface of the glass substrate (1) or by other methods. It is advisable to see the rough area become opaque and frosted;

[0022] 2) Sputtering a layer of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com