Tire deformation online testing device and testing method based on light streams

An online testing and tire technology, applied in tire measurement, measuring devices, optical devices, etc., can solve the problems of complex sensor structure, complex calculation model, difficult tire layout, etc., achieve high-speed image capture, stable and reliable system, and reduce burden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

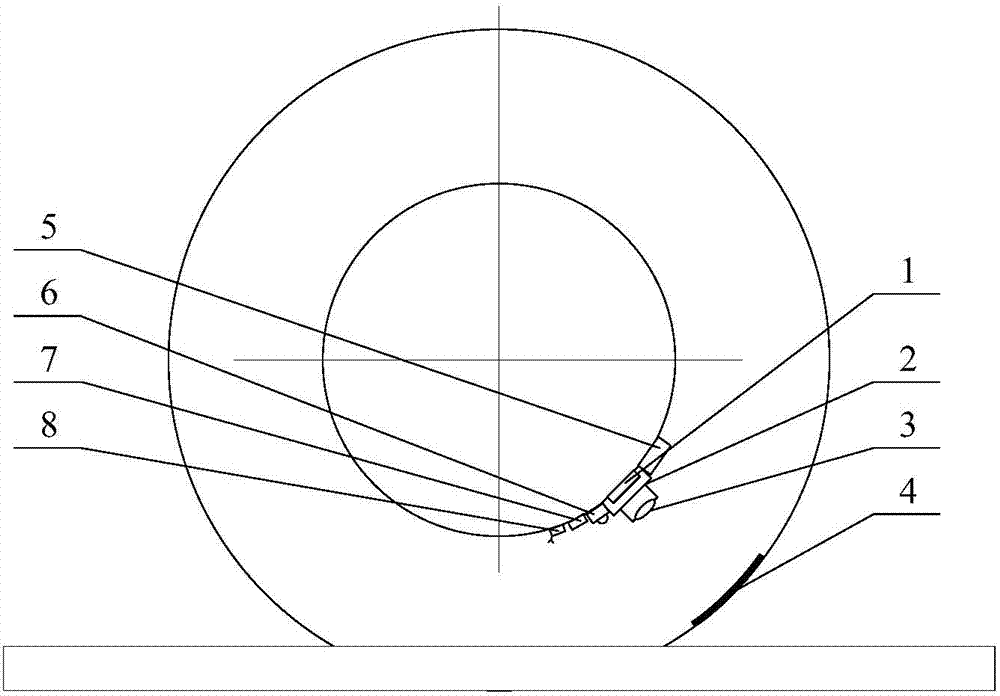

[0019] refer to figure 1 and figure 2 , a tire deformation measurement device, including: an optical flow sensor 1, a lens holder 2, a lens 3, a reflective surface 4, a single-chip microcomputer 5, a light source 6, a wireless transmission module 7, and a battery 8.

[0020] Wherein, the reflective surface 4 is located at the inner surface of the tire tread, and the reflective surface 4 is coated with a reflective coating to realize the recognition of the lateral and longitudinal deformation of the tire carcass. An optical flow sensor 1, a lens bracket 2, a lens 3, a single-chip microcomputer 5, a light source 6, a wireless transmission module 7, and a battery 8 are fixedly connected to the rim directly above it. Wherein, one end of the lens bracket 2 is fixedly connected to the optical flow sensor 1 , and the other end is fixedly connected to the lens 3 .

[0021] refer to Figure 5 , the electrical connection relationship of the present invention is as follows: the optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com