Extrusion machine liquid charging valve and extrusion machine with same

A technology of extruder and liquid filling valve, which is applied in the direction of press machine, valve operation/release device, lift valve, etc. The effect of saving pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the invention is capable of various changes in different embodiments without departing from the scope of the invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

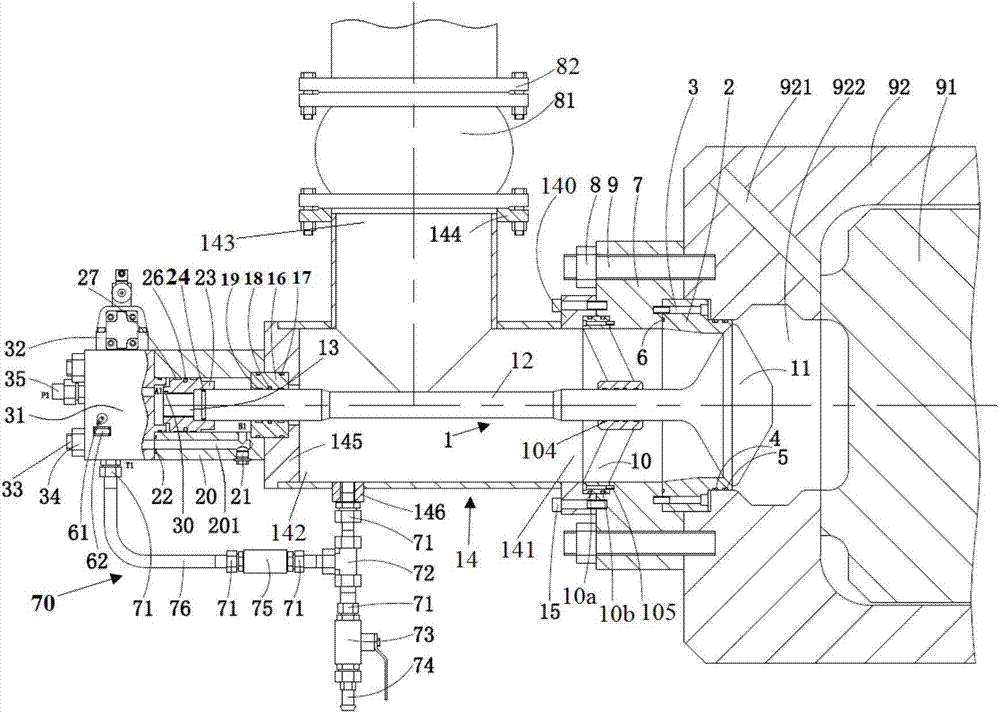

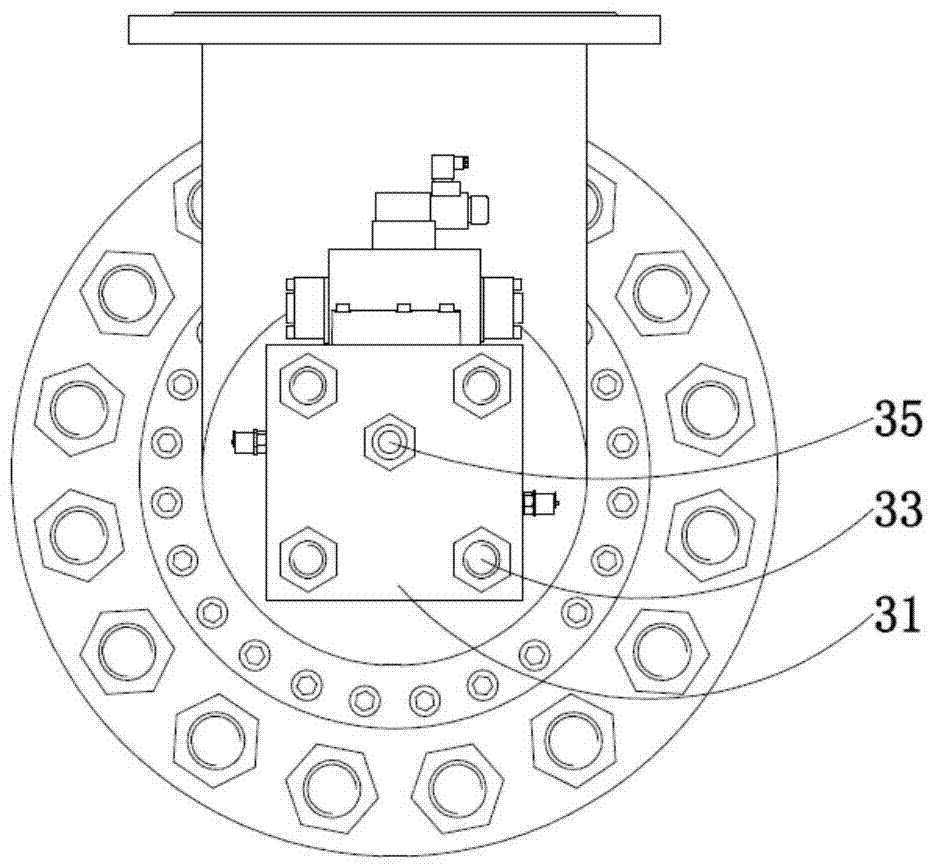

[0043] Such as figure 1 As shown, the liquid filling valve for an extruder of the present invention includes a valve core 1 , a valve body 14 , a rear hydraulic cylinder 20 , a solenoid valve 32 and an oil return pipeline 70 .

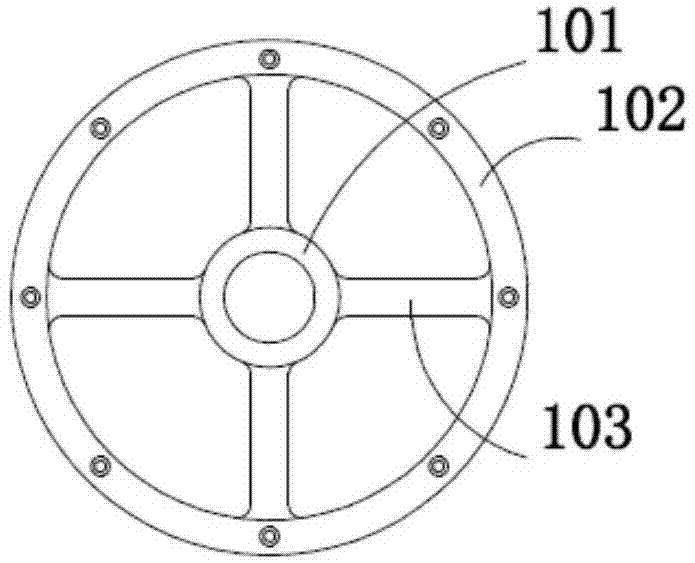

[0044] The main cylinder 92 of the extruder is cylindrical, and a plunger 91 is arranged in the inner space of the main cylinder 92. A high-pressure oil pipe 921 and a liquid injection and discharge hole 922 are provided on the rear end surface of the main cylinder 92 respectively. The liquid filling and draining hole 922 can be located at the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com