Single mechanical seal with elastic sealing ring and double mechanical seal with elastic sealing ring

An elastic seal and mechanical seal technology, which is applied to mechanical equipment, engine seals, engine components, etc., can solve the problems of difficulty in manufacturing mechanical seal parts, limited floating range of floating friction rings, and inability to maintain fit seals, etc., to achieve Save material, good floating effect, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the improvement made by the present invention to the prior art, before describing in detail the single-end mechanical seal and the double-end mechanical seal with elastic sealing rings of the present invention, the combination of the prior art mentioned in the background technology section The accompanying drawings illustrate.

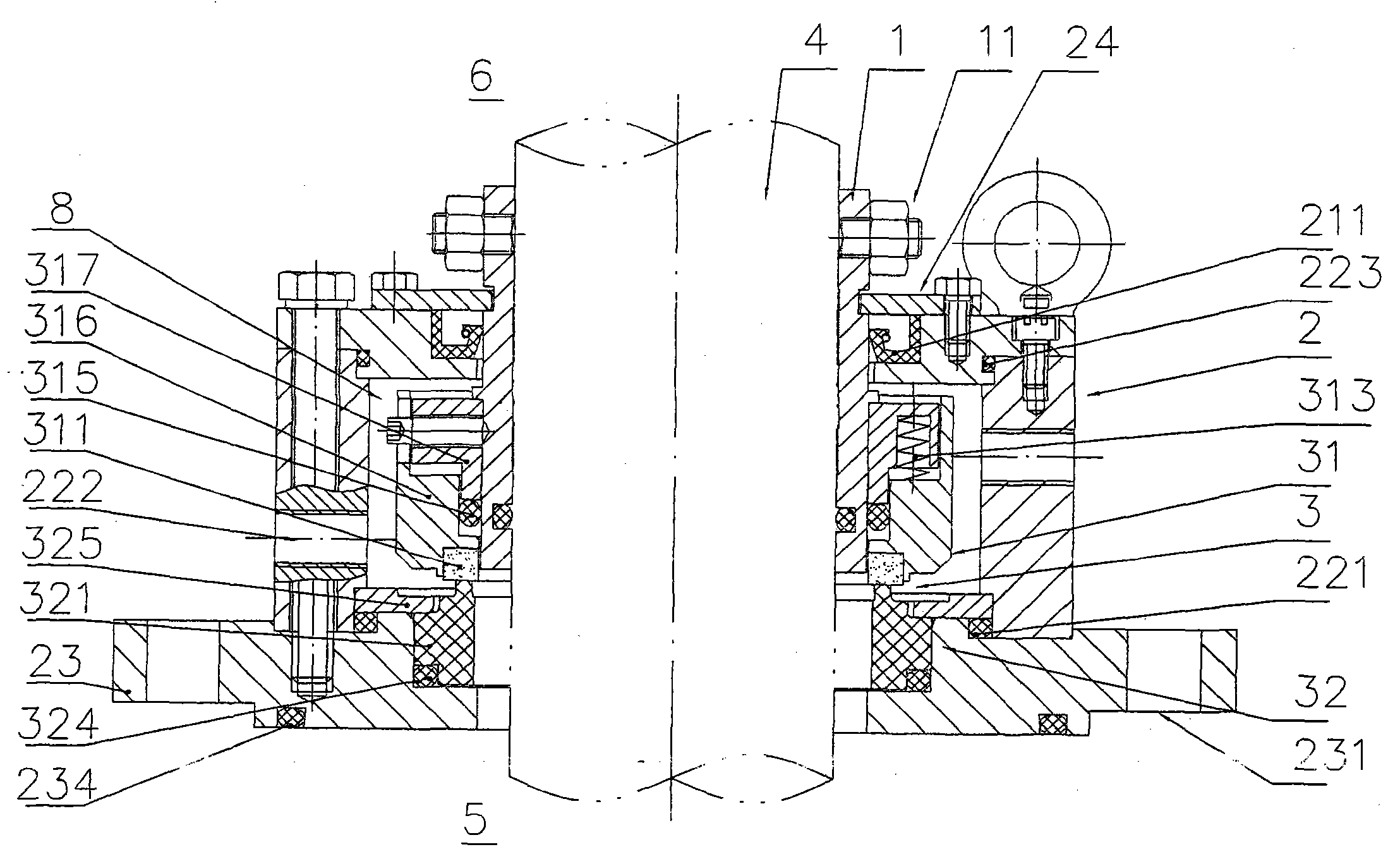

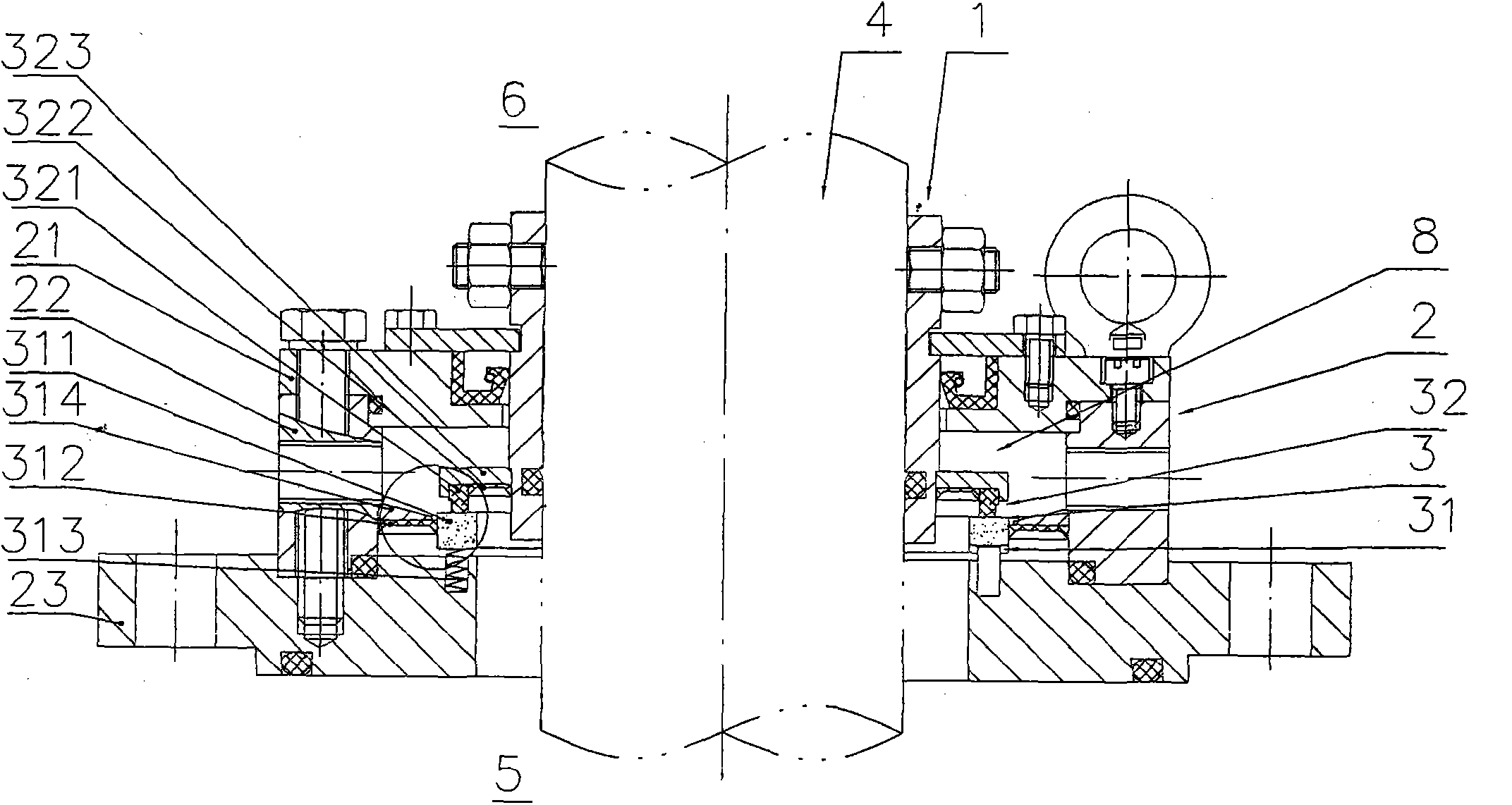

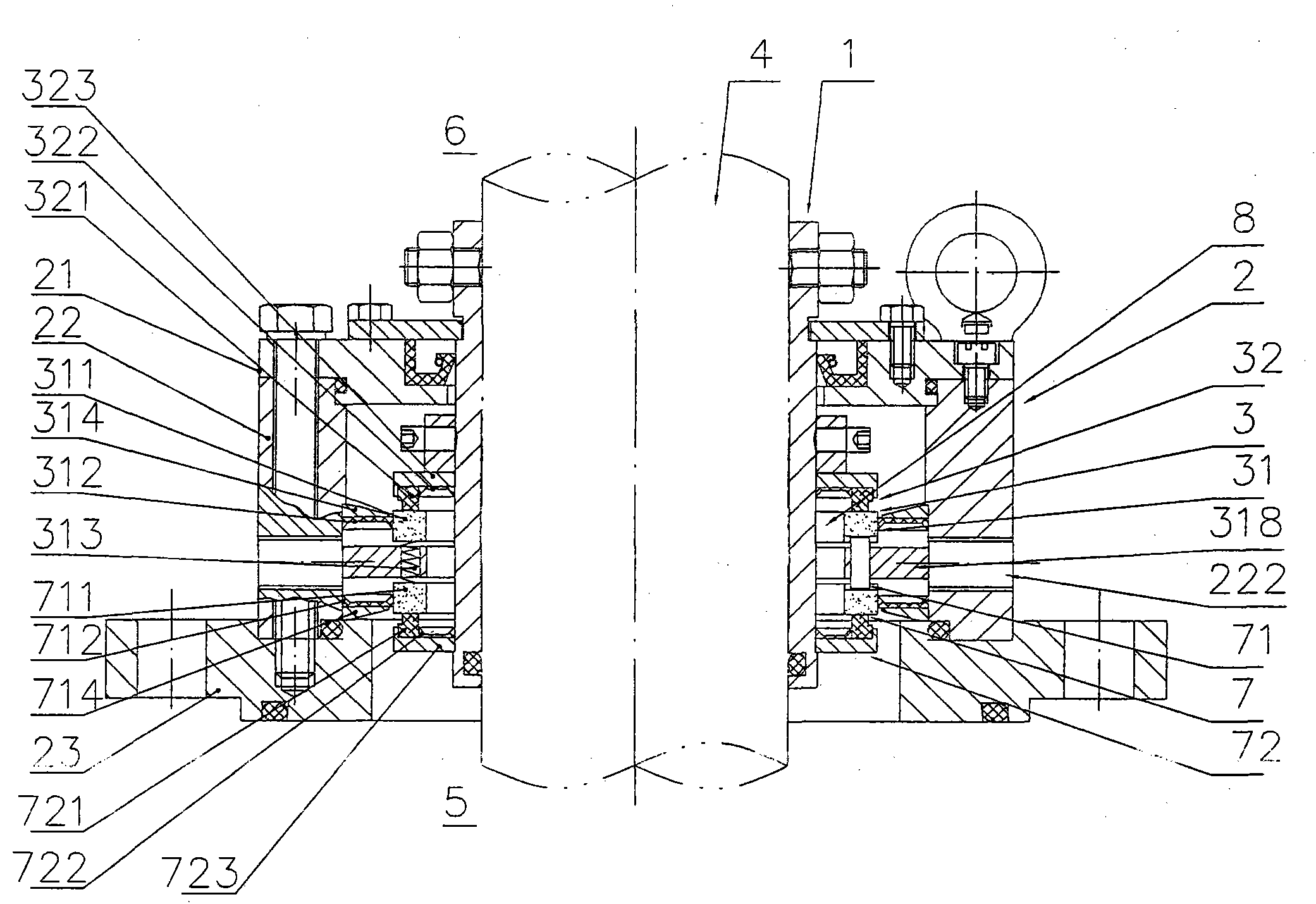

[0015] figure 1 The shown existing mechanical seal structure includes a shaft sleeve 1 fitted on a rotating shaft 4 , a sealing box 2 located on the periphery of the shaft sleeve 1 , and a pair of friction pairs 3 placed between the sealing box 2 and the shaft sleeve 1 . The friction pair 3 includes a floating ring assembly 31 and a fixed ring assembly 32 . The floating friction ring 311 in the floating ring assembly 31 realizes sealing and floating support by means of its supporting seat 316, the O-shaped elastic sealing ring 315 between the supporting seat 316 and the sleeve 1, and the spring 313 supporting the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com