Method for preparing fullerene flower balls on surface of soft matrix

A fullerene curd, fullerene technology, applied in organic chemistry, textile and papermaking, fiber processing, etc., can solve the problems of high fullerene content, weakened fullerene optoelectronic properties, small specific surface area, etc. The effect of high fullerene content, simple and rapid preparation method, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In a 100 ml single-necked volumetric flask, add 0.0582 g of C 60 , 0.0110 grams of methyl / ethyl p-formylbenzoate, 0.0381 grams of sarcosine and 30 milliliters of toluene, refluxed at 115 ° C for 5 hours under nitrogen protection, separated and purified, and obtained methyl p-benzoate and ethyl p-benzoate substituted fullerene derivatives. Characterized by MALDI-TOF-MS, I, m / z calcd911.8; found911.1; II, m / z calcd925.9; found925.2.

Embodiment 2

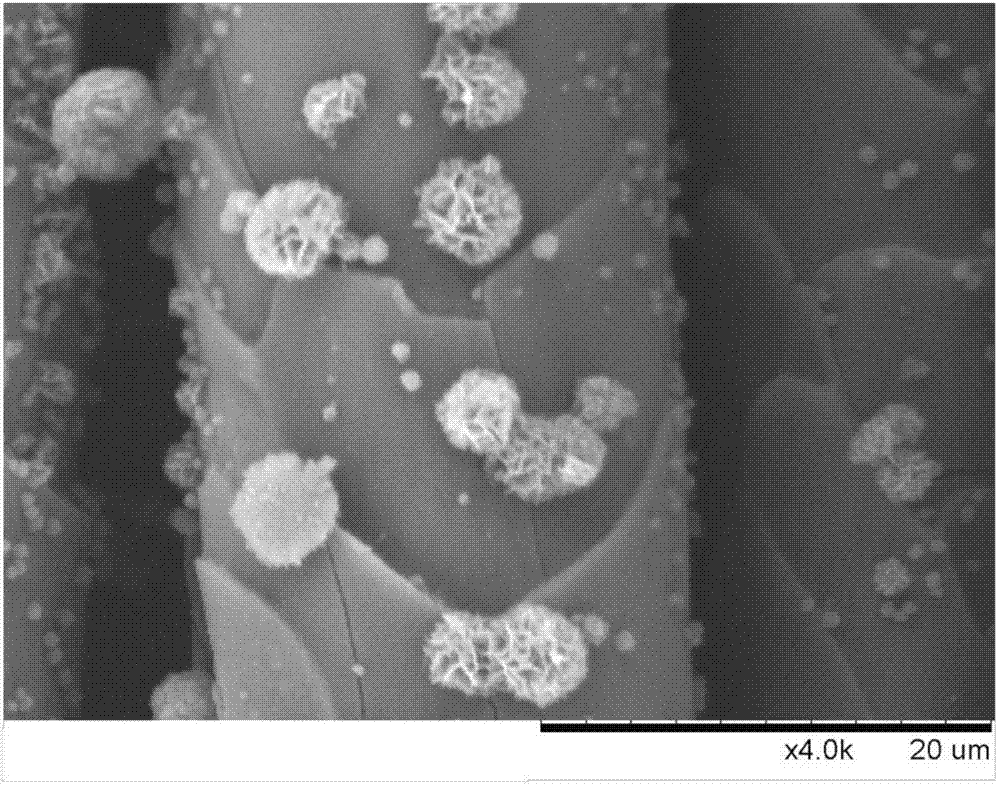

[0029] Fullerene curds were prepared on wool fabric surface using fullerene derivative I.

[0030] Cut the wool fabric into square pieces of about 0.25 square centimeters in size with scissors, rinse the surface with acetone, and let it dry naturally; use a pipette gun to take out 20 μl of 1 mg / ml fullerene derivative I in chloroform-ethanol (volume ratio 10:1) solution, drop directly on the wool fabric substrate, and naturally volatilize until dry; spray gold on the substrate with fullerene self-assembly structure for 20 seconds, and observe with Hitachi TM-1000 scanning electron microscope, you can see the wool fabric The prepared fullerene curds on the surface of the fabric ( figure 1 ).

Embodiment 3

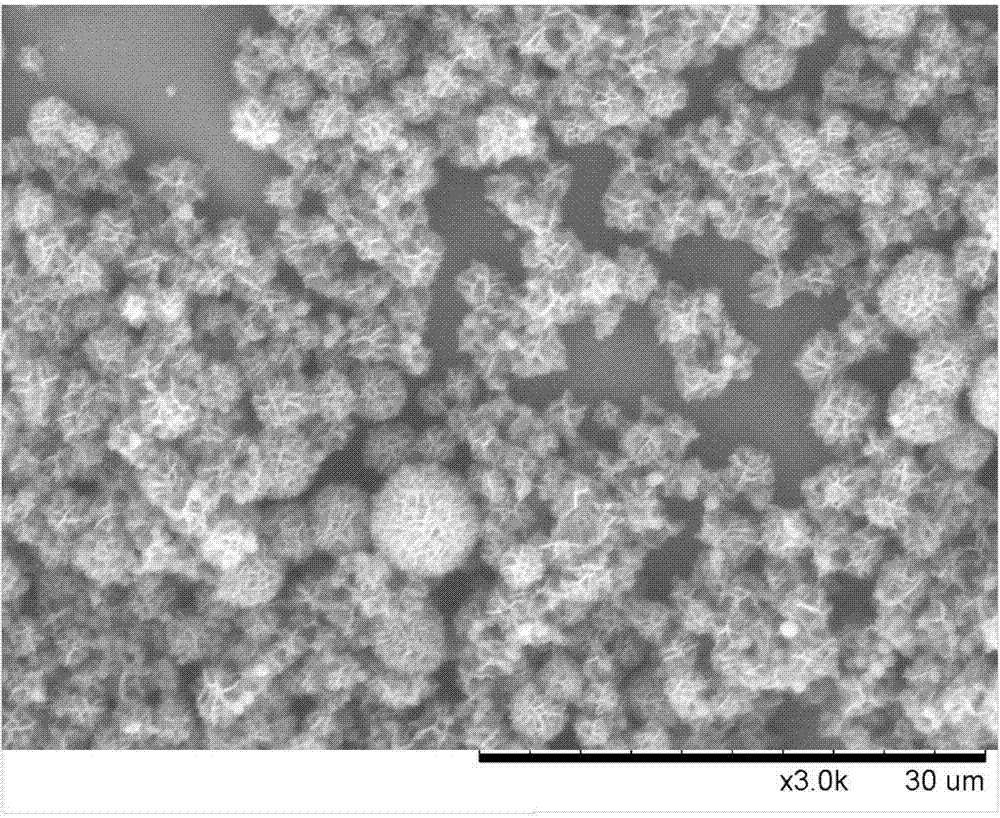

[0032] Preparation of fullerene curds on nylon plastic surface using fullerene derivative I.

[0033] Cut the nylon plastic into square pieces about 0.25 cm2 in size with scissors, rinse the surface with acetone, and let it dry naturally; use a pipette gun to take out 20 μl of 1 mg / ml fullerene derivative I in chloroform-ethanol (volume ratio 10:1) solution, drop directly on the nylon plastic substrate, and naturally volatilize to dryness; spray gold on the substrate with the fullerene self-assembly structure for 20 seconds, and observe with the Hitachi TM-1000 scanning electron microscope, you can see the nylon Fullerene curds prepared on plastic surfaces ( figure 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com