Hydride vapour phase epitaxy equipment

A hydride gas phase and epitaxy technology, which is applied in the direction of chemically reactive gases, chemical instruments and methods, crystal growth, etc., can solve the problems that the substrate cannot be easily realized, the capacity is limited, and it is not safe.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

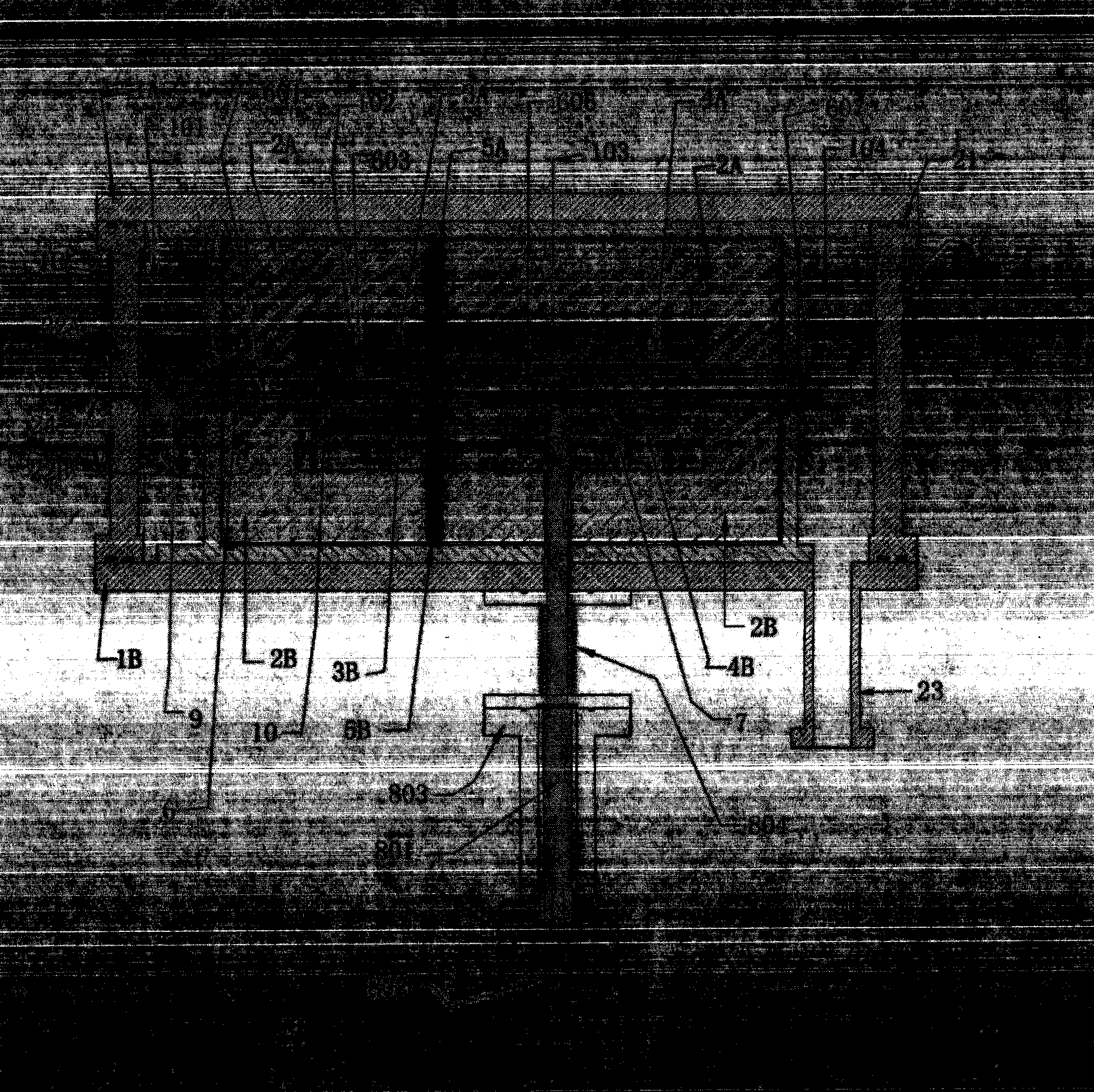

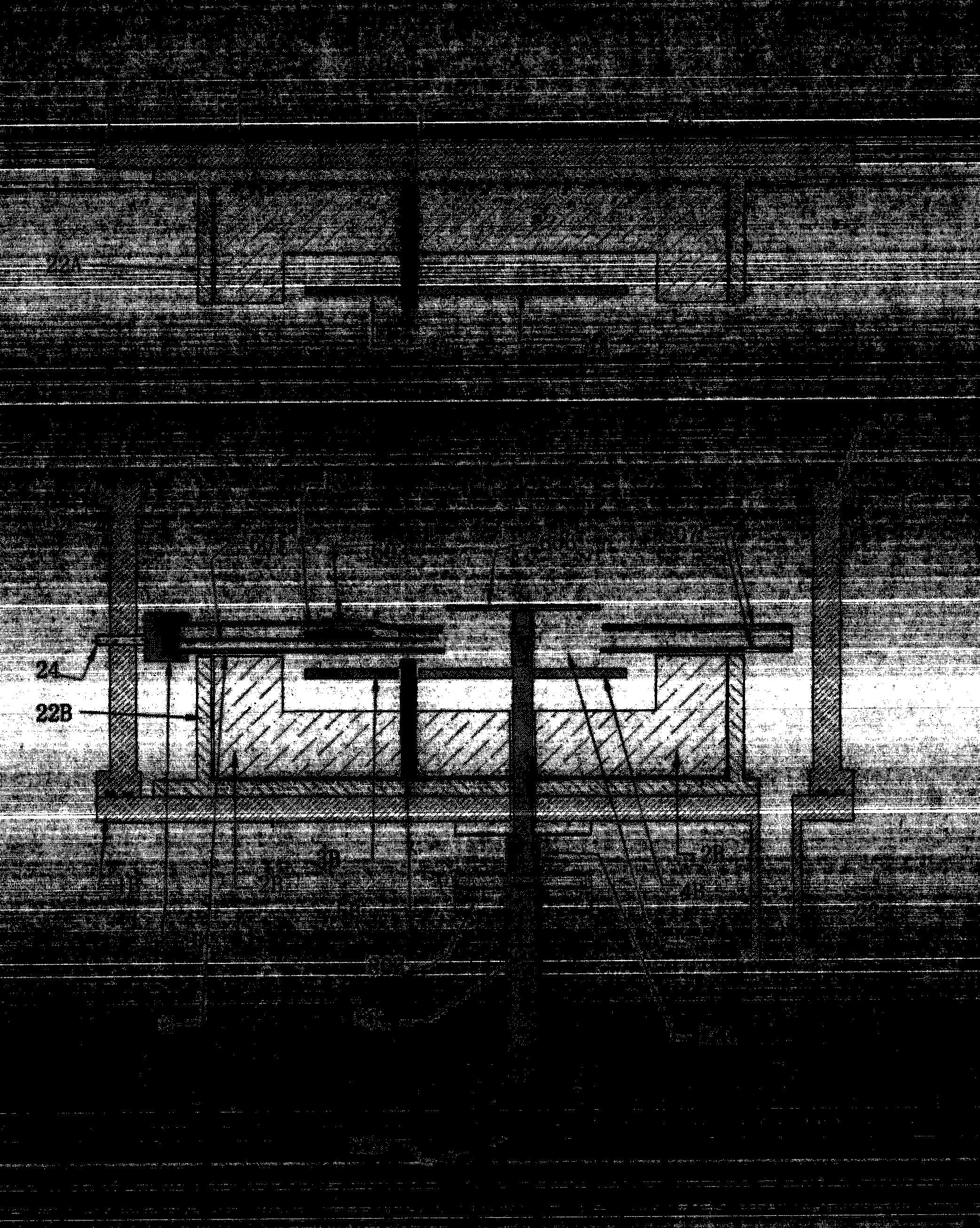

[0039] to combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 It is a specific embodiment of the present invention. The HVPE equipment includes: water-cooled stainless steel chamber (1), insulation layer (2), source heater (3), substrate heater (4), chamber insulator (5), internal reaction chamber (6), Substrate tray (7), tray rotating and lifting mechanism (8), gas injection port (9), metal boat (10), etc.

[0040] The water-cooled stainless steel chamber (1) is divided into three parts, which are respectively an upper cover plate (1A), a lower base plate (1B), and a wall plate (1C), and the middle is sealed with an apron (21), which together form a whole (such as figure 1 shown). The function of the water-cooled stainless steel chamber (1) is to separate the air from the interior of the chamber, and preserve the pressure inside the chamber (1) through the pressure control device. The upper cover plate (1A), the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com