Device and method for preparing biodiesel

A biodiesel and material recycling technology, applied in the fields of biofuel, petroleum industry, liquid carbon-containing fuel, etc., can solve the problems of low conversion efficiency and long reaction time, increase the mass transfer surface, improve the effect, and increase the mass transfer area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings.

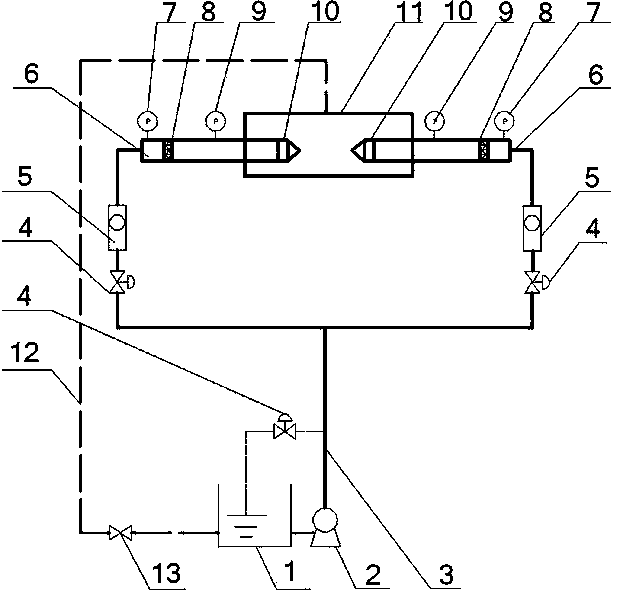

[0034] The structure of a device for preparing biodiesel in the present invention is as follows: figure 1 As shown, including piping system, reaction system and measurement system, where:

[0035] The pipeline system includes a raw material circulation storage box 1, a material circulation pump 2, an inflow pipeline 3, a return pipeline 12, an adjustable butterfly valve 4 for controlling the flow in two symmetrically arranged hydraulic cavitation reactors 6, and a valve installed in the backflow The non-adjustable butterfly valve 13 on the pipeline 12; the two symmetrically arranged branches equipped with the hydraulic cavitation reactor 6 are connected in parallel, the upstream end is connected to the material circulation pump 2 through the inflow pipeline 3, and the downstream end is connected to the material circulation pump 2 through the return pipe The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com