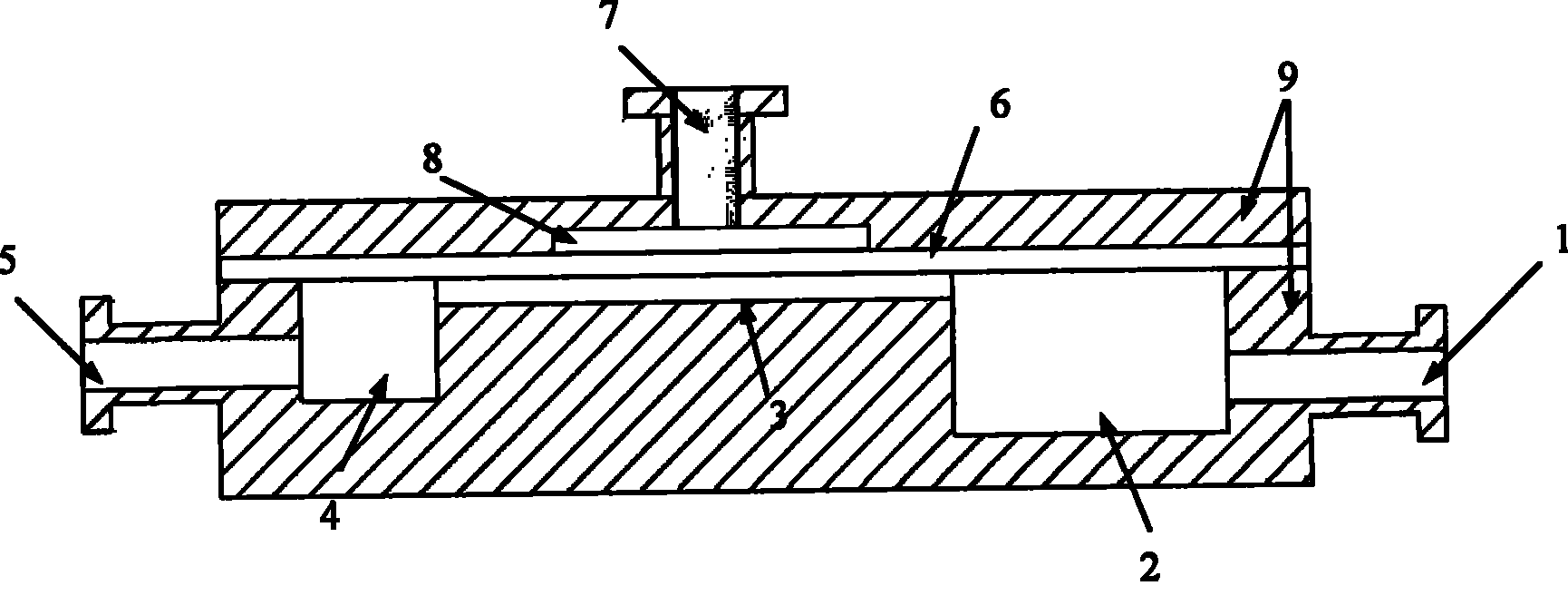

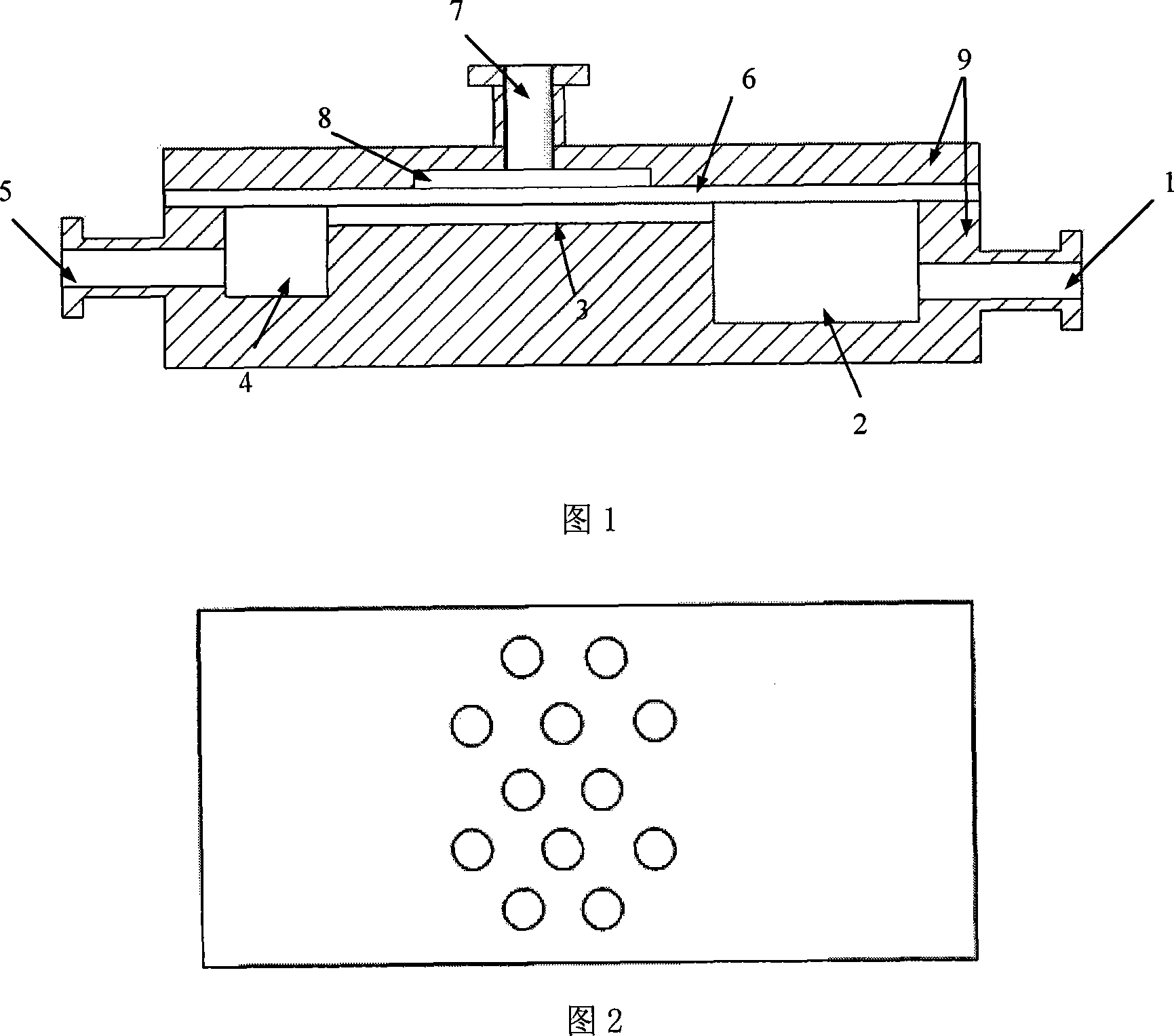

Reactor or mixer with micromesh structure

A technology of micro-sieves and reactors, applied in fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of low mixing efficiency, long reaction cycle, poor mixing effect, etc., and achieve large mass transfer area , short mass transfer distance and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A single-channel micro-reactor with a micro-sieve structure is used to prepare nano-barium sulfate particles. Among them, the hydraulic diameter of the micro-sieve is 15 μm, the opening rate is 5%, and the hole spacing is 0.3 mm. The mixing channel is 1 mm wide and 0.2 mm high. Sodium sulfate solution is used as the first fluid, and its distribution chamber volume is 9 times of the total volume of the mixing channel, and barium chloride is used as the second fluid, and its distribution chamber volume is 0.4 times of the total volume of the mixing channel, and the volume of the product collection chamber is 1 times the total volume of the mixing channel. The average particle size of the reaction product nano barium sulfate is 42nm.

Embodiment 2

[0019] Amidation pre-mixing reaction is carried out by using a 20-channel micro-reactor with a micro-sieve structure. Among them, the hydraulic diameter of the micro-sieve is 10 μm, the opening ratio is 25%, and the hole spacing is 1 mm. The mixing channel is 8mm wide and 15mm high. CCA n-hexane solution is used as the first fluid, and its distribution chamber volume is 20 times of the total volume of the mixing channel. Fuming sulfuric acid enters the mixing channel as the second fluid through the sieve, and its distribution chamber volume is 20 times of the total volume of the mixing channel. 2.5 times, the volume of the product collection chamber is twice the total volume of the mixing channel. The reaction selectivity was 95%.

Embodiment 3

[0021] A micro-reactor with a micro-sieve structure of 1000 channels is used to carry out the preparation reaction of nano-calcium carbonate. Among them, the hydraulic diameter of the micro-sieve is 1000 μm, the opening ratio is 1%, and the hole spacing is 3 mm. The mixing channel is 100mm wide and 20mm high. Ca(0H) 2 With aqueous solution as the first fluid, the distribution chamber volume is 100 times the total volume of the mixing channel, CO 2 -N 2 As the second fluid, the mixed gas passes through the sieve hole and enters the mixing channel. The volume of the distribution chamber is 5 times the total volume of the mixing channel, and the volume of the product collection chamber is 10 times the total volume of the mixing channel. The reaction product is calcium carbonate particles with an average particle diameter of 61nm and good monodispersity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com