Improved internal electrolytic iron bed apparatus for treating water

A water treatment device and internal electrolysis technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Dirt is not easy to clean effectively, to achieve the effect of maintaining high activity, thorough sewage discharge and thorough cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

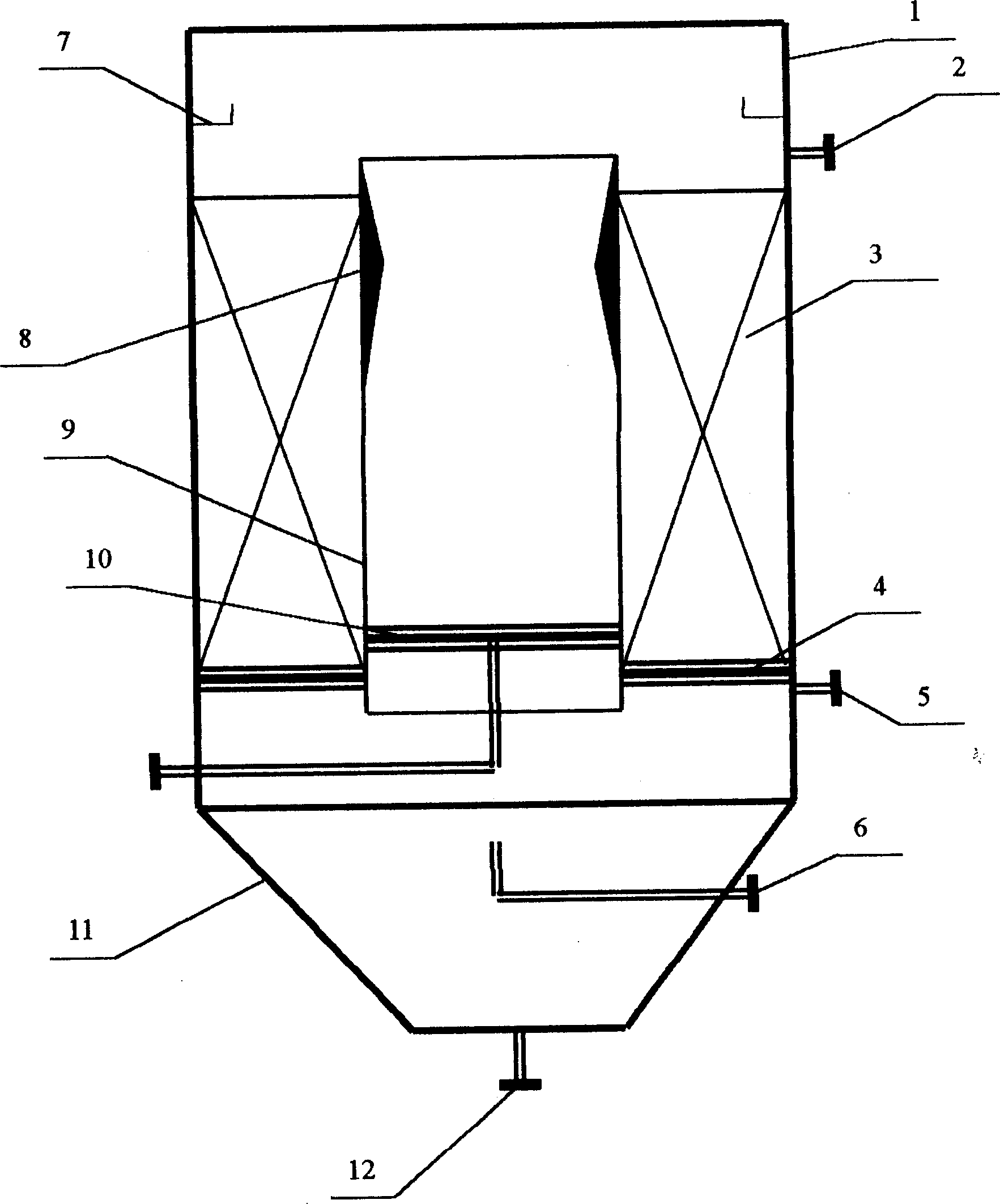

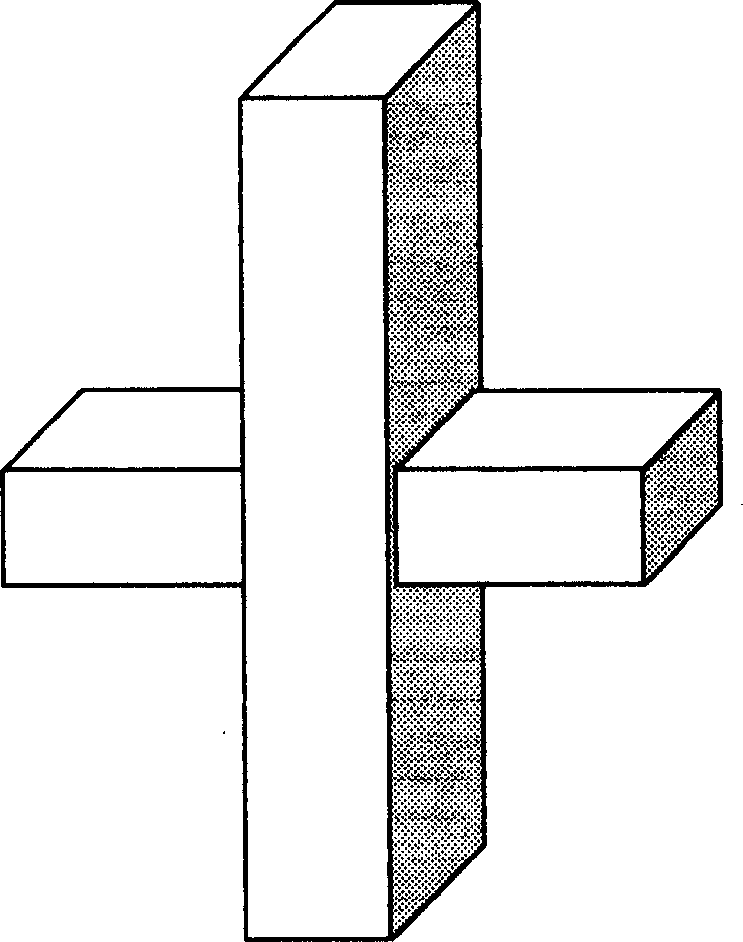

[0012] Example 1: see figure 1 , an inner electrolytic iron bed water treatment device, including an outer cylinder 1, an axially built-in inner circulation cylinder 9, a filler shelf 4 and an aeration tube 5 at the bottom of the interlayer of the inner and outer cylinders, and a built-in three-dimensional polyhedral iron filler 3 ( Figure 3-10 ), there is an aeration pipe 10 at the lower bottom of the inner circulation cylinder, a balanced triangular guide ring 8 on the inner side of the upper end, a defoaming ring groove 7 on the upper inner side of the top of the cylinder body, a conical mud collecting bucket 11 at the lower bottom, and the water inlet pipe 6 is located at In the lower part of the cylinder, the outlet pipe 2 is below the defoaming ring groove.

Embodiment 2

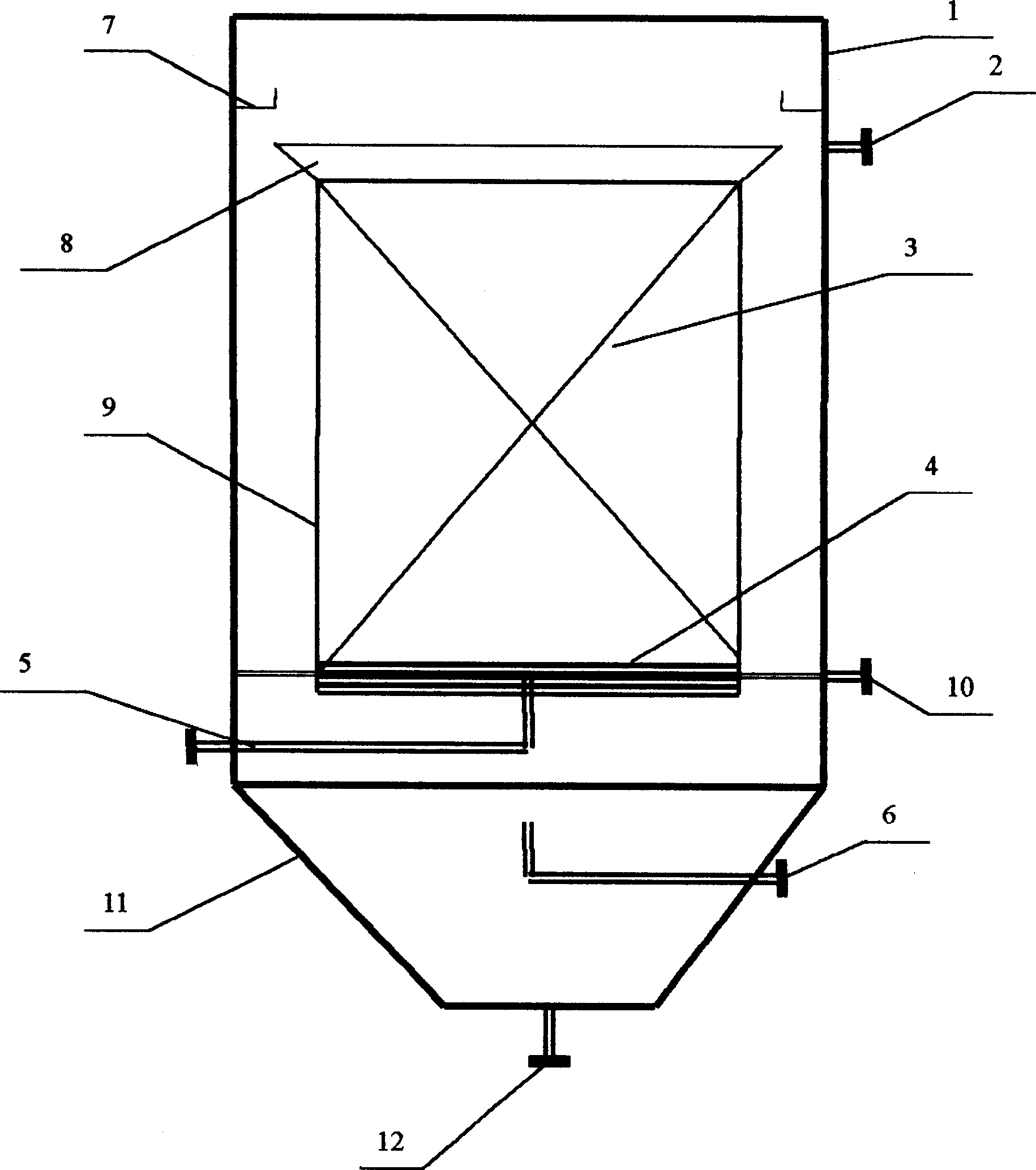

[0013] Example 2: see figure 2 , as mentioned above, increase the central cylinder 9, place the iron filler 3 in the central cylinder, and the outlet of the central cylinder has a balanced diversion bell mouth 8. The iron filler preferably adopts a cross structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com