Crystallization method for p-xylene

A p-xylene and crystallization technology, applied in the field of p-xylene crystallization, can solve the problems of serious fouling of the precooler, difficulty in crystal washing, high energy consumption, etc., achieve refrigeration energy saving, good technical effect, and solve the problem Severe effect of scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A crystallization method for separating p-xylene according to the present invention.

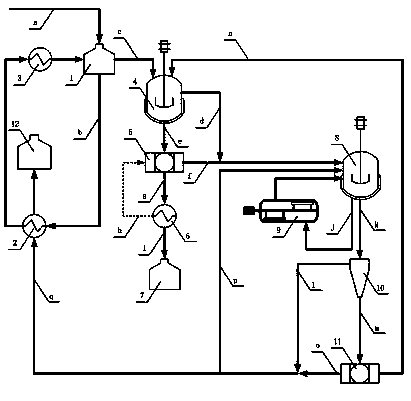

[0027] like figure 1 Said, the mixed xylene raw material a enters the raw material tundish 1, the temperature is 30°C, the flow rate is 1075kg / h, the p-xylene content is 80wt%, a part of the raw material b is pre-cooled by the mother liquid heat exchanger 2 and the precooler 3 After returning to the raw material tundish 1, the flow rate is 5375 kg / h, a part of raw material c enters the crystal slurry tank 4 to heat up the crystal, the flow rate is 1075 kg / h, and the temperature is 15°C. The operating temperature of the magma tank 4 is 3.5° C. The overflow mother liquor d flows out from the top into the tank crystallizer 8 for crystallization, and the concentrated magma e is separated by the solid-liquid separator 5 to obtain the filtered mother liquor f and p-xylene crystals g. The filtered mother liquor f enters the kettle crystallizer 8 for crystallization, the crystallization temp...

Embodiment 2

[0030] The crystallization method of producing p-xylene described in the present invention.

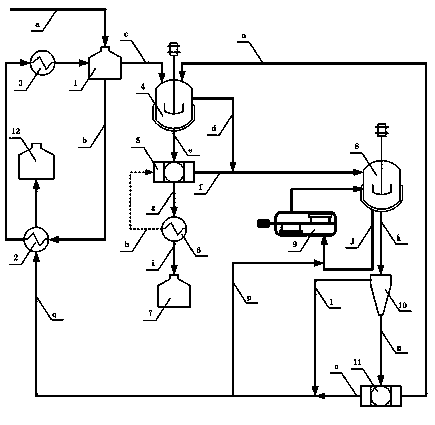

[0031] According to the operating condition of embodiment 1, adopt as figure 2 In the crystallization method for producing p-xylene, the flow rate of mixed xylene raw material b is 10750 kg / h.

[0032]

Embodiment 3

[0034] The crystallization method of producing p-xylene described in the present invention.

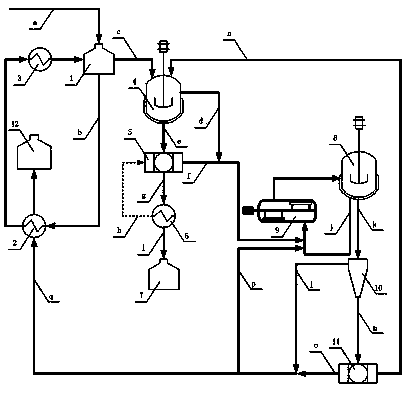

[0035] According to the operating condition of embodiment 1, adopt as image 3 In the crystallization method for producing p-xylene, the flow rate of mixed xylene raw material b is 16125kg / h.

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com