Magnesium-aluminum multilayer composite plate and machining method thereof

A multi-layer composite and aluminum alloy sheet technology, which is applied in the direction of chemical instruments and methods, lamination, lamination equipment, etc., can solve the problems of increasing processing workload, being vulnerable to corrosion, and difficult to achieve the ideal shape of the product plate, etc. Achieve the effect of easy control, good binding force and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

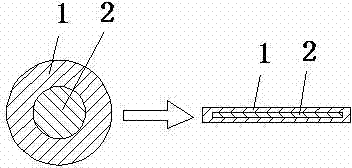

[0039] The original size of the outer ingot billet (that is, the cladding substrate 1) is Φ80x110mm, which is 6082 alloy. at 560 0 C Homogenization treatment for 6 hours, dig a hole of Φ40x110mm in the round ingot, prepare AZ31 ingot of Φ40x110mm (ie core material 2), at 400 0 After C homogenization treatment for 10 hours, the steel balls on the surface are washed and then put into 6082 ingots. 0 C for 1h at 460°C in a mold measuring 3x56mm 0 C extruded to obtain the plate. Extruded products are relatively stable in size, the actual size is 3x58mm see figure 1 .

example 2

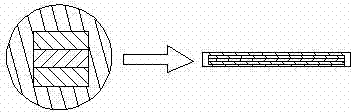

[0041] The original size of the outer ingot billet (that is, the cladding substrate 1) is a Φ80x110mm round ingot with an inner square hole of 42x42x110mm, which is a 6082 alloy. And a 110x42x14mm aluminum alloy plate 6082, at 560 0 C homogenization treatment for 6 hours, two 110x42x14mm magnesium alloy plates AZ31, 400 0 C. Homogenize for 10 hours, use mechanical processing to remove obvious defects, and then use a wire brush to polish the surface, and cross-stack them into the square holes of 6082 ingots. 400 in the furnace 0 C after 1.5h of heat preservation, in a mold with a size of 3x56mm at 400 0 C extruded to obtain the plate. The size of the extruded product is relatively stable, and the actual size is 2.8x60.2mm. See figure 2 .

example 3

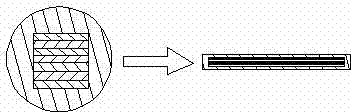

[0043] The original size of the outer ingot billet (that is, the cladding substrate) is a Φ80x110mm round ingot with an inner square hole of 42x42x110mm, which is 6082 alloy. And three 110x42x6mm aluminum alloy plates 6082, at 560 0 C homogenization treatment for 6 hours, four 110x42x6mm magnesium alloy plates AZ31, 400 0C. Homogenize for 10 hours, use mechanical processing to remove obvious defects, and then use a wire brush to polish the surface, and cross-stack them into the square holes of 6082 ingots. 400 in the furnace 0 C after 1.5h of heat preservation, in a mold with a size of 3x56mm at 400 0 C extruded to obtain the plate. The size of the extruded product is relatively stable, and the actual size is 2.8x60.8mm. See image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com