Method for preparing carbon fiber guide wheel for cutting silicon chips and carbon fiber guide wheel

A carbon fiber and carbon fiber tube technology, applied in the field of carbon fiber guide wheels, can solve the problems of shortening the production cycle, complicated production process, and low strength of the guide wheel, and achieve the effects of shortening the production cycle, simplifying the manufacturing process, and promoting flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing a carbon fiber guide wheel for cutting silicon wafers in this embodiment comprises the following steps:

[0040] (1) Preparation of resin: place the resin in an oven and heat it for 1 to 2 hours in advance, then add the curing agent, then pour the resin into a vacuum tank to evacuate, and stir evenly at a high speed to ensure that the resin and the curing agent are fully mixed, and the internal There are no air bubbles to ensure that the carbon fiber guide wheel has sufficient strength and service life; the above-mentioned resin is epoxy resin, and the heating temperature is 80-120°C; the curing agent is an acid anhydride curing agent.

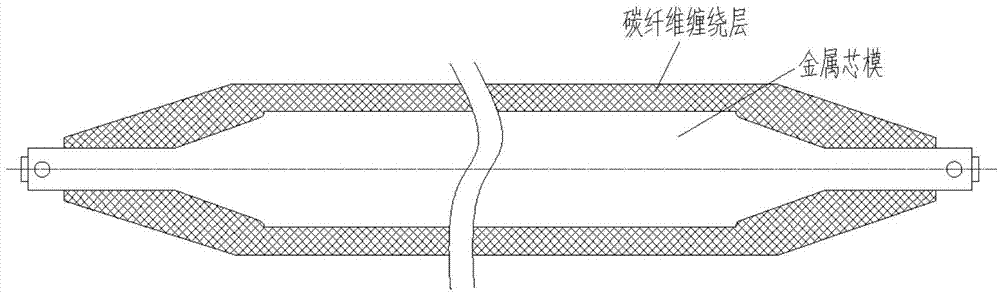

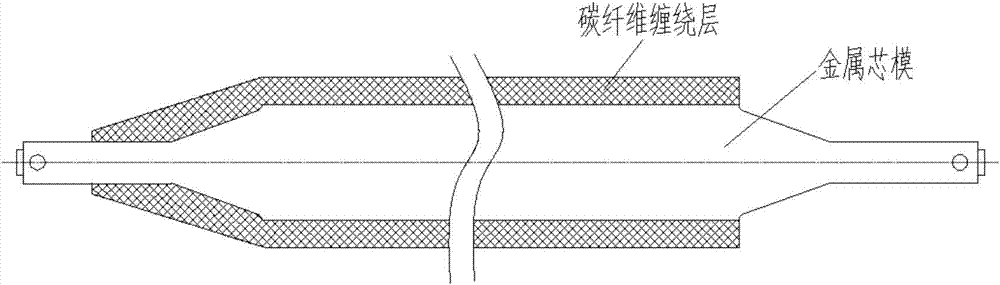

[0041](2) Mandrel preheating: place the metal mandrel in an oven, keep the temperature at 30°C for 1 to 2 hours, then hoist the mandrel on the winding station of the three-dimensional winding machine and fix it, and prepare for winding and preheating The purpose of the mandrel is to promote the flow of the resin a...

Embodiment 2

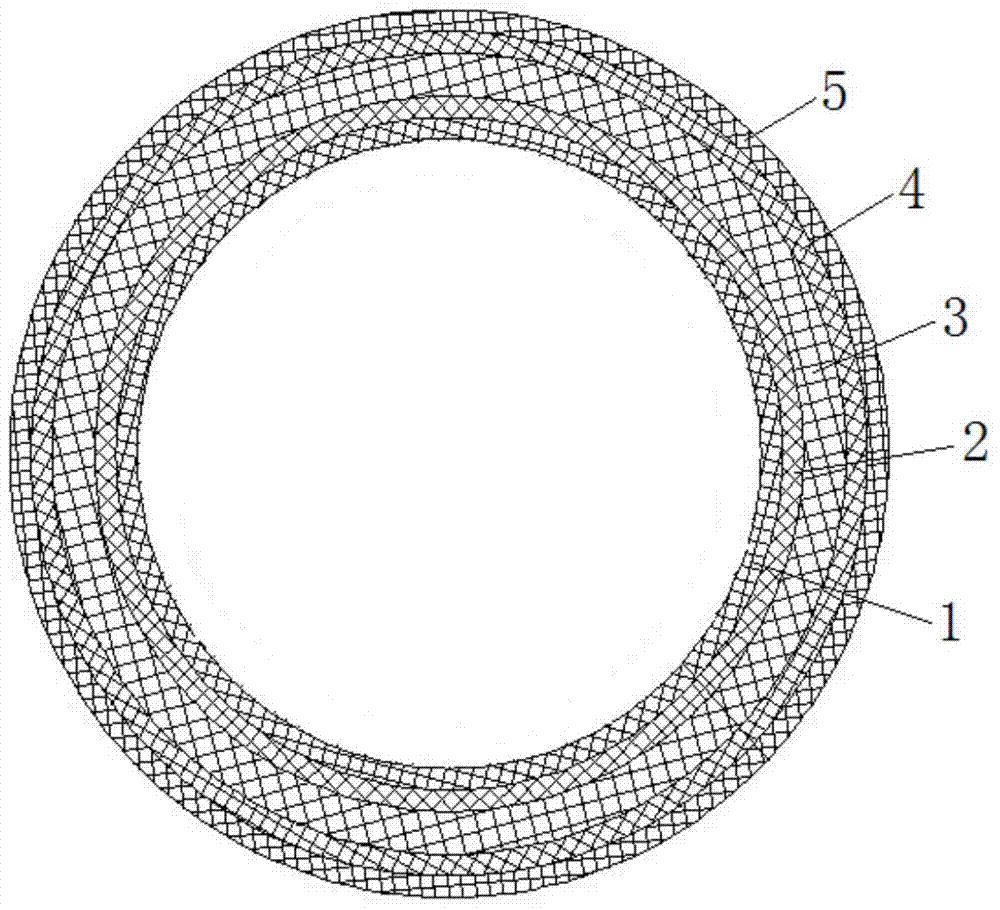

[0049] A method for preparing a carbon fiber guide wheel for cutting silicon wafers in this embodiment and a carbon fiber guide wheel are basically the same as in Example 1, except that the method for preparing a carbon fiber guide wheel for cutting silicon wafers in this embodiment, The layup in step (3) is designed as follows: the winding angles of the carbon fiber yarns are, in order from the inside to the outside, 7mm at 50°, 7mm at 35°, 15mm at 15°, 7mm at 35° and 50° ° Winding 7mm to prepare a medium-sized carbon fiber guide wheel; the above-mentioned winding angle refers to the complementary angle between the carbon fiber yarn and the axis of the metal mandrel; in step (4), control the resin content to 35% for winding. In this embodiment, a carbon fiber guide wheel produced by the above carbon fiber guide wheel preparation method, the winding angle of the first winding layer 1 is 50°, and the winding thickness is 7mm; the winding angle of the second winding layer 2 is 35...

Embodiment 3

[0051] A method for preparing a carbon fiber guide wheel for cutting silicon wafers in this embodiment and a carbon fiber guide wheel are basically the same as in Example 1, except that the method for preparing a carbon fiber guide wheel for cutting silicon wafers in this embodiment, The layup design in step (3) is as follows: the winding angles of the carbon fiber yarns are, in order from inside to outside, 60°winding 8mm, 40°winding 8mm, 20°winding 20mm, 40°winding 8mm and 60° ° Winding 8mm to prepare a larger carbon fiber guide wheel; the above winding angle refers to the residual angle of the angle formed by the carbon fiber yarn and the axis of the metal mandrel; in step (4), control the resin content to 40% for winding. In a carbon fiber guide wheel produced by the above carbon fiber guide wheel preparation method in this embodiment, the winding angle of the first winding layer 1 is 60°, and the winding thickness is 8 mm; the winding angle of the second winding layer 2 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com