On-line microelectrode manufacturing method

A technology of micro-electrode and manufacturing method, which is applied in the direction of electrode manufacturing, manufacturing tools, electric processing equipment, etc., can solve problems such as difficulties, and achieve the effect of avoiding influence and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

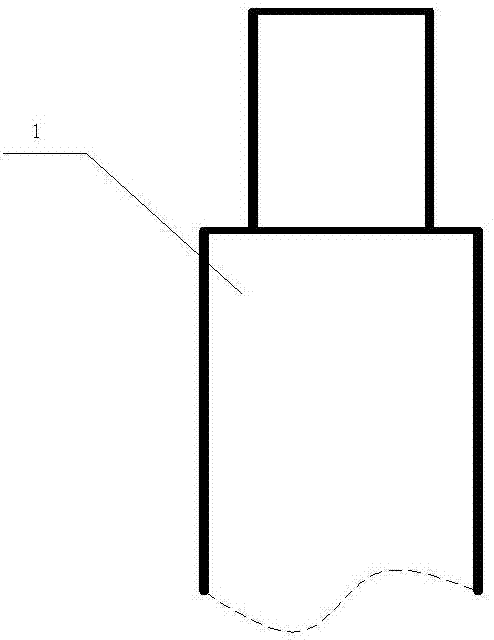

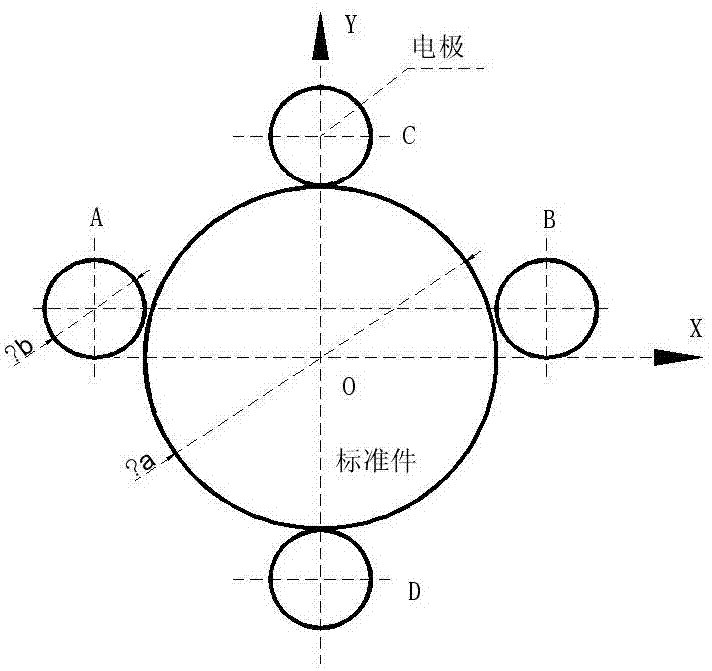

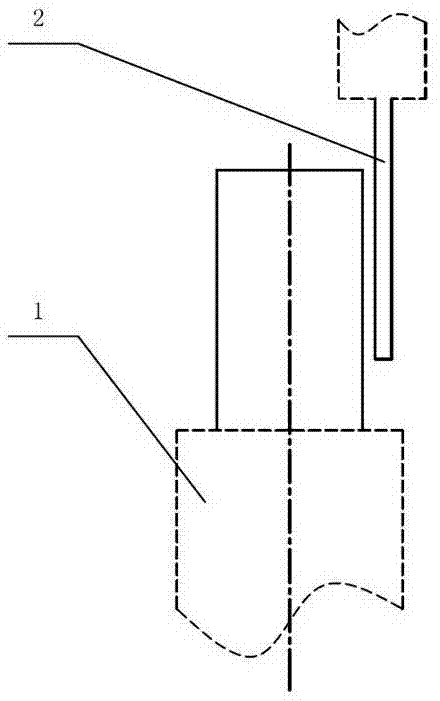

[0021] figure 1 It is a schematic diagram of the structure of the cylindrical reverse copy electrode of the electric discharge milling process in the present invention, figure 2 It is a schematic diagram of the electrode diameter online detection in the present invention;

[0022] The on-line manufacturing method of the micro-electrode of the present invention is used to prepare the micro-electrode with an outer diameter and a length of 200 μm. The preparation process of the fine electrode is as follows:

[0023] (1) The counter-copy electrode is processed by CNC turning, and the counter-copy electrode 1 is cylindrical, such as figure 1 shown;

[0024] (2) Install the anti-copy electrode 1 on the EDM machine tool, and mill the anti-copy electrode by EDM technology. During the processing, the electrode rotates around its own axis to remove the error...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com