inkjet recording device

An inkjet recording and inkjet head technology, which is applied to printing devices, printing, etc., can solve the problems of mixed dust and poor ejection, avoid the influence of pressure, protect the negative pressure forming part, and shorten the time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

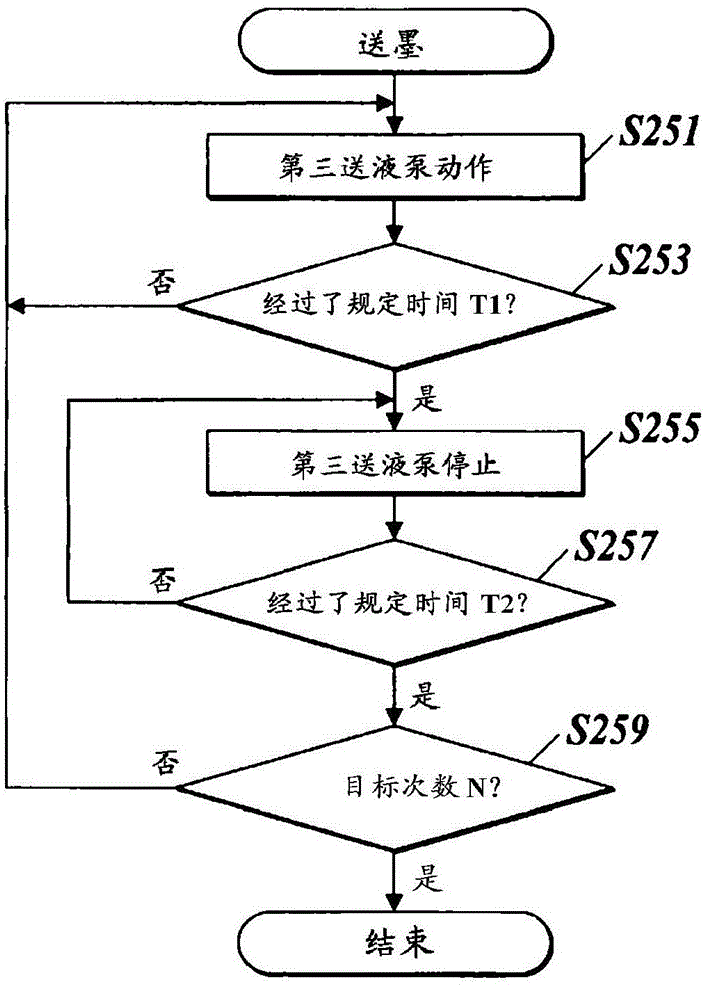

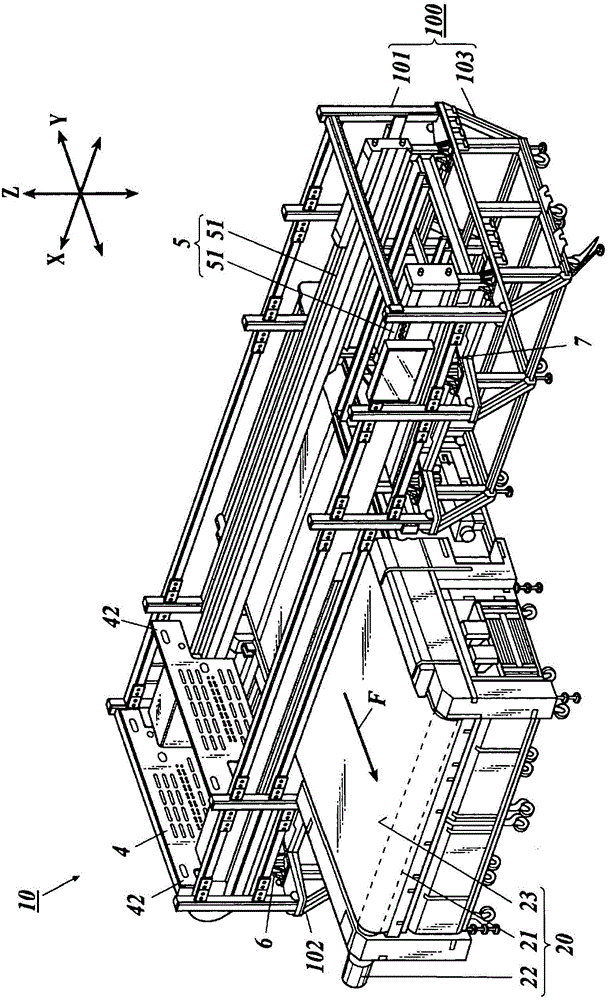

[0049] based on Figure 1 to Figure 13 An inkjet recording device 10 equipped with an ink supply device according to an embodiment of the present invention will be described. figure 1 It is a perspective view showing the entire inkjet recording device 10 .

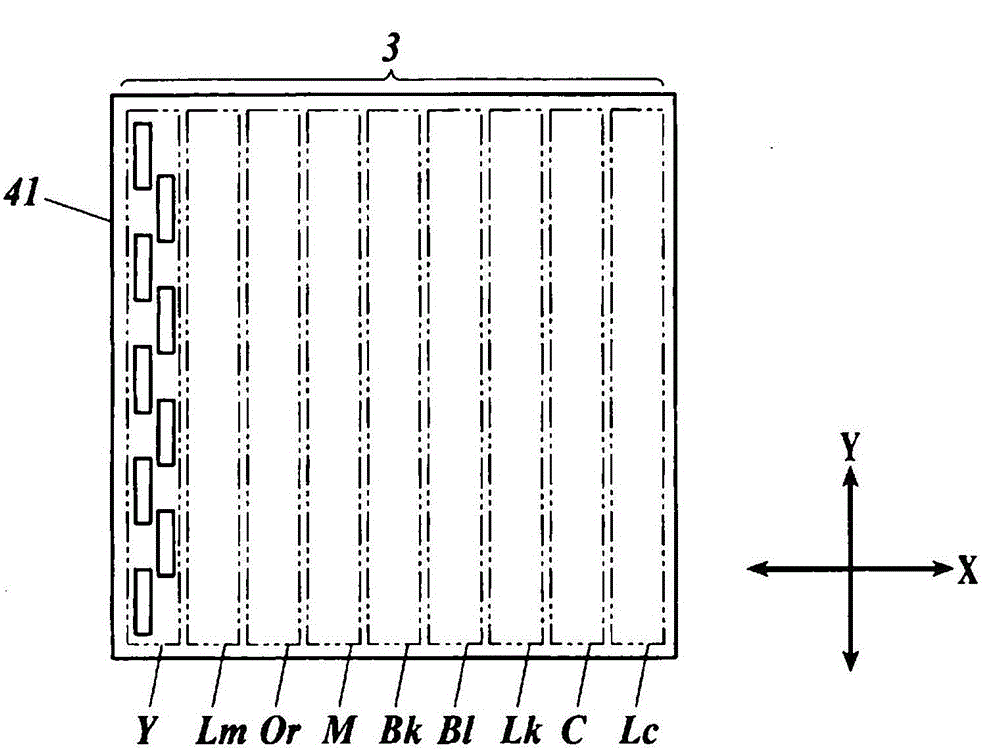

[0050] The inkjet recording device 10 mainly has a conveying device 20 that conveys a recording medium in the horizontal direction, and a plurality of inkjet heads 3 that eject ink from the conveyed recording medium from above (refer to figure 2), the main scanning device 5 that transports the carriage 4 along the horizontal direction perpendicular to the conveying direction of the recording medium, the maintenance unit 7 that performs maintenance on each inkjet head 3 mounted on the carriage 4, and the The nozzle moisturizing unit 6 for moisturizing the nozzles 311 of each inkjet head 3 on the carriage 4, and the ink supply device 8 for supplying ink to each inkjet head 3 mounted on the carriage 4 (refer to Figure 4 )...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com