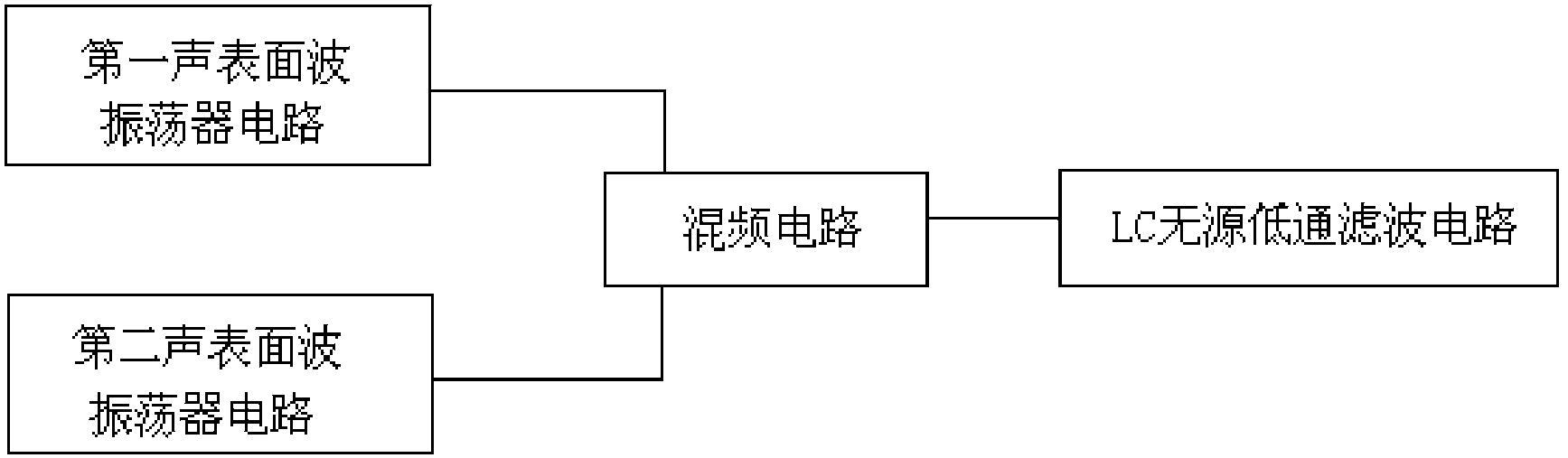

Application circuit of surface acoustic wave transducer

A surface acoustic wave device and surface acoustic wave technology, applied in the field of sensors, can solve problems such as the unsatisfactory output waveform of the surface acoustic wave oscillator, the inability to measure the physical quantity to be measured, and the submersion of the measured signal, so as to achieve small impedance, easy measurement, The effect of high-precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Surface acoustic wave devices SAW1 and SAW2 both use surface acoustic wave devices with multiple couplers with a center frequency of 50.882MHz, capacitor C13=C23=C14=C24=27pF; high-frequency low-power tubes BJT1 and BJT2 have a cut-off frequency of 6.5GHz NPN type C3355 silicon transistor. When winding the inductance coil, for the sake of simple calculation, the diameter D of the coil is taken as 1Cm, and the length L of the coil is N Take 1Cm, then determine L and the number of turns N of the coil according to formulas (1), (2), and (3), and calculate L12=L22=725nH, N=10.

[0052] During the production process of the first surface acoustic wave oscillator and the second surface acoustic wave oscillator, due to the difference in the distribution of the devices and the difference in the parameters of the same device, the first surface acoustic wave oscillator and the second surface acoustic wave oscillator output different frequencies signal of. Pass the test of the ap...

Embodiment 2

[0054] The surface acoustic wave devices SAW1 and SAW2 use multiple couplers with a center frequency of 101.764MHz, and the capacitance value is C13=C23=C14=C24=27pF; the high-frequency low-power tubes BJT1 and BJT2 are NPN with a cut-off frequency of 7GHz Type C3358 silicon triode; inductance coil diameter D=1Cm, length L N =1Cm, calculated according to formula (1), (2), (3) to get L12=L22=188nH, N=5. Observe the signal waveforms of the waveform output port of the first SAW oscillator, the waveform output port of the second SAW oscillator and the difference frequency signal output port of the two oscillators respectively through the Agilent oscilloscope, and the output waveforms are as follows: Figure 6 , Figure 7 , Figure 8 shown. in, Figure 6 The waveform frequency is 101.224MHz, Figure 7 The waveform frequency is 100.712MHz, Figure 8 The waveform frequency is 434.23KHz. The data shows that the application circuit of the surface acoustic wave sensor can output th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrolytic capacitor | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

| Inductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com