Flow battery

A liquid flow battery and reaction solution technology, applied in fuel cells, regenerative fuel cells, circuits, etc., can solve the problems of reduced circulation flow efficiency, strong corrosion and toxicity, and low battery energy density, and achieve improved cycle efficiency and no Toxic and corrosive, abundant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Positive electrode reaction solution:

[0089] Add 32 parts by volume of positive electrode active material α-manganese dioxide (average particle size is 5 μm), 3 parts by volume of positive electrode conductive agent Ketjen black (average particle size is 5 μm) into the positive electrode electrolyte (1mol / L sulfuric acid zinc solution), stir evenly to make a positive electrode reaction solution (the volume fraction of the positive electrode active material and the positive electrode conductive agent in the positive electrode reaction solution is 35%).

[0090] Negative electrode reaction solution:

[0091] Prepare the negative electrode electrolyte (4mol / L zinc sulfate solution) to make the negative electrode reaction solution.

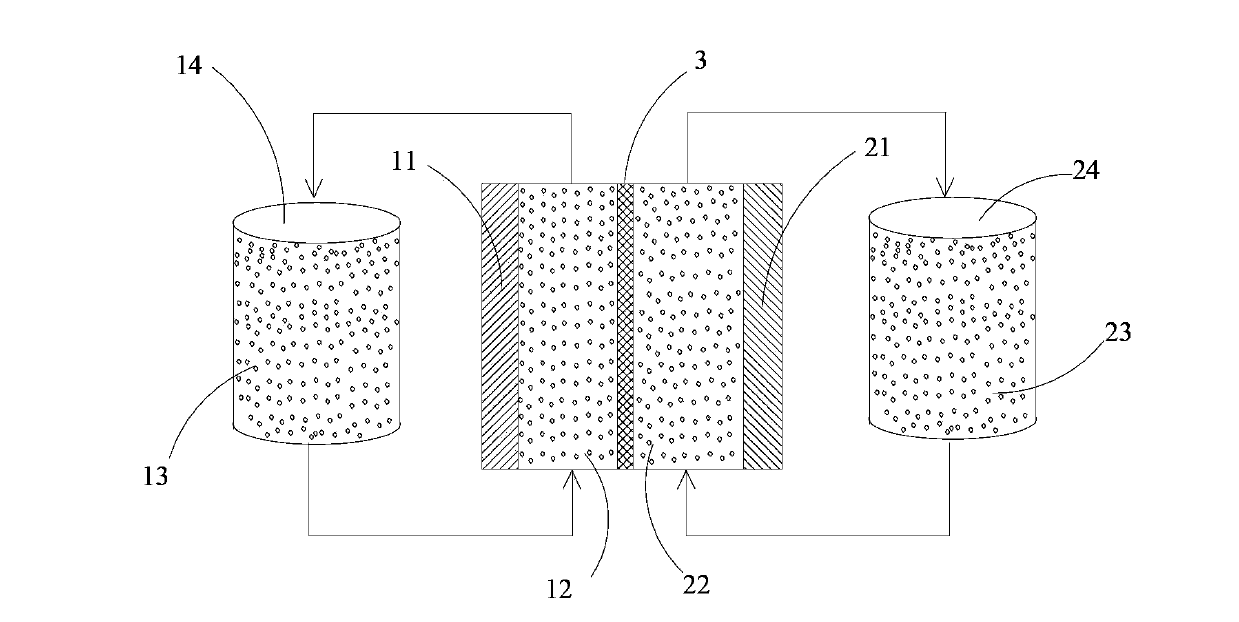

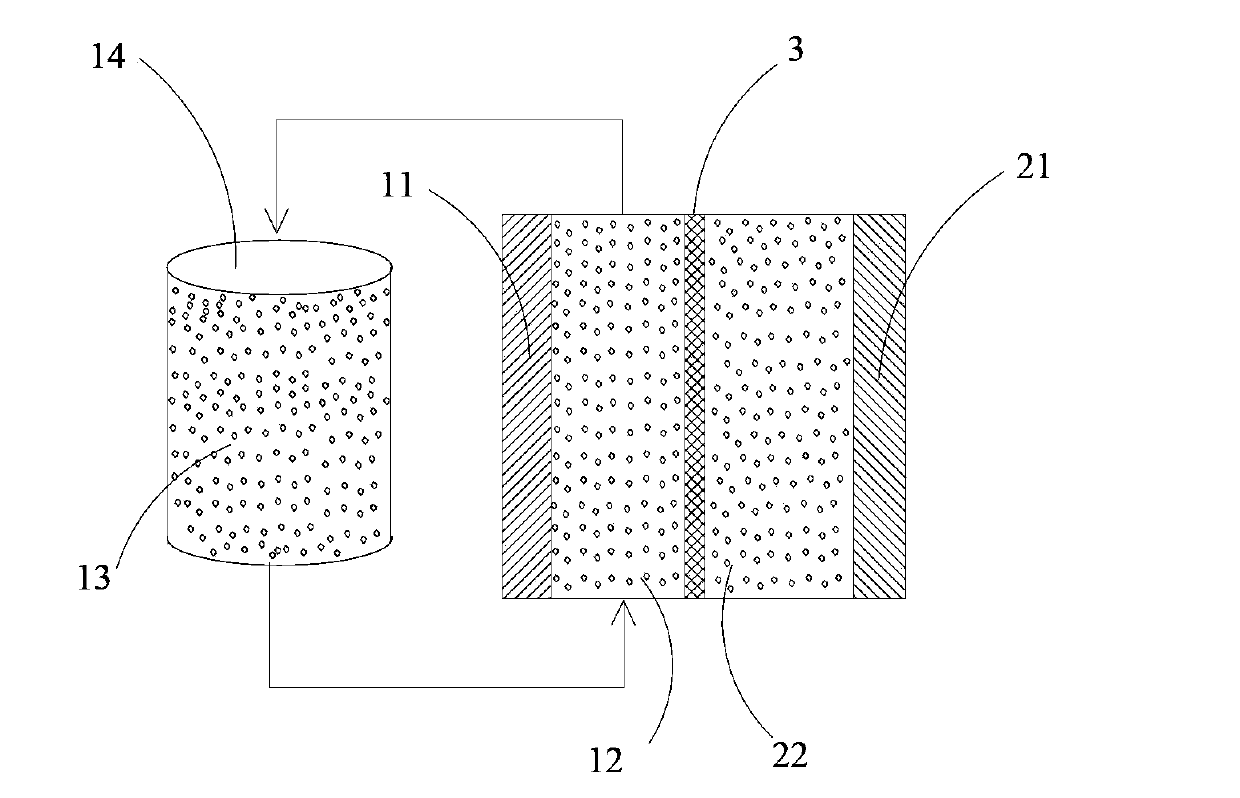

[0092] Assemble the battery:

[0093] Assemble the positive and negative electrode collectors and diaphragms to form the positive and negative electrode reaction areas, and then use pipes to connect the positive and negative electrode react...

Embodiment 2

[0095] Positive electrode reaction solution:

[0096] 24 parts by volume of positive electrode active material ZnMn 2 o 4 (the average particle size is 10 μm), 1 volume part of the positive electrode conductive agent carbon nanotube (the average particle size is 5 μm) is added in the positive electrode electrolyte (1mol / L zinc sulfate solution), stir evenly, make the positive electrode reaction solution ( The volume fraction of the positive electrode active material and the positive electrode conductive agent in the positive electrode reaction solution is 25%).

[0097] Negative electrode reaction solution:

[0098] Add 24 parts by volume of negative electrode active material zinc powder (average particle size of 5 μm) and 1 volume part of negative electrode conductive agent Ketjen black (average particle size of 10 μm) into the negative electrode electrolyte (2mol / L zinc sulfate solution) , stir evenly to make a negative electrode reaction solution (the volume fraction of ...

Embodiment 3

[0102] Positive electrode reaction solution:

[0103] 16 parts by volume of positive electrode active material ZnMn 2 o 4 (average particle size of 5 μm), 1 volume part of the positive electrode conductive agent Ketjen black (average particle size of 20 μm) was added to the positive electrode electrolyte (3mol / L zinc nitrate solution), and stirred evenly to make the positive electrode reaction solution (the volume fraction of the positive electrode active material and the positive electrode conductive agent in the positive electrode reaction solution is 17%).

[0104] Negative electrode reaction solution:

[0105] Prepare the negative electrode electrolyte (4mol / L zinc sulfate solution) to make the negative electrode reaction solution.

[0106] Assemble the battery:

[0107] Assemble the positive and negative electrode current collectors and diaphragms to form the positive and negative electrode reaction areas; then connect the positive electrode reaction area with the pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com