Preparation method of fes2 thin film

A thin film, fe2o3 technology, applied in the field of FeS2 thin film and its preparation, can solve the problems of low photoelectric conversion efficiency and poor light absorption performance, and achieve the effect of increasing effective light absorption area, improving photoelectric conversion efficiency, and enhancing light absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

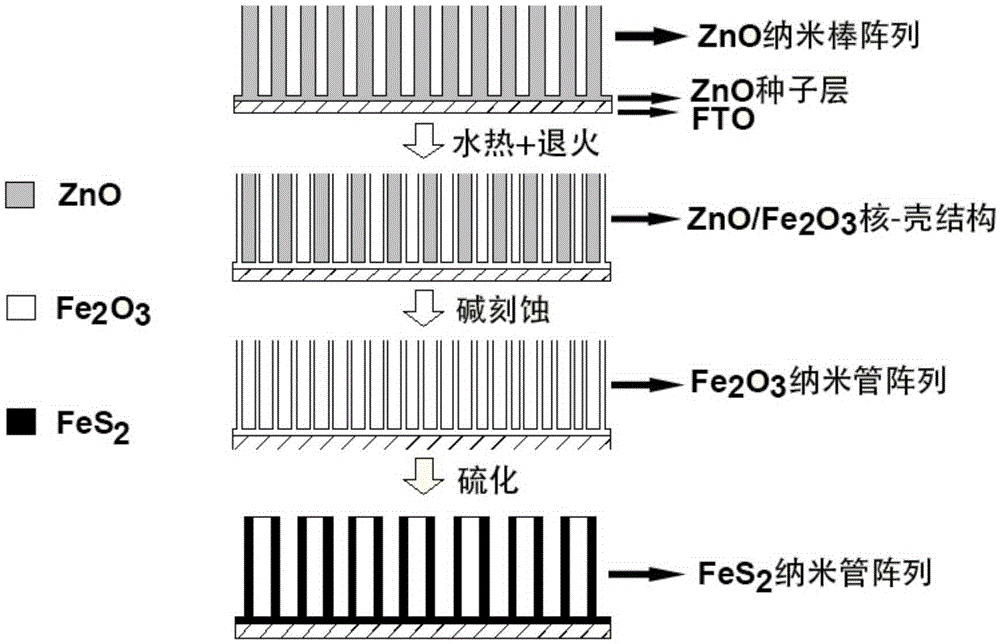

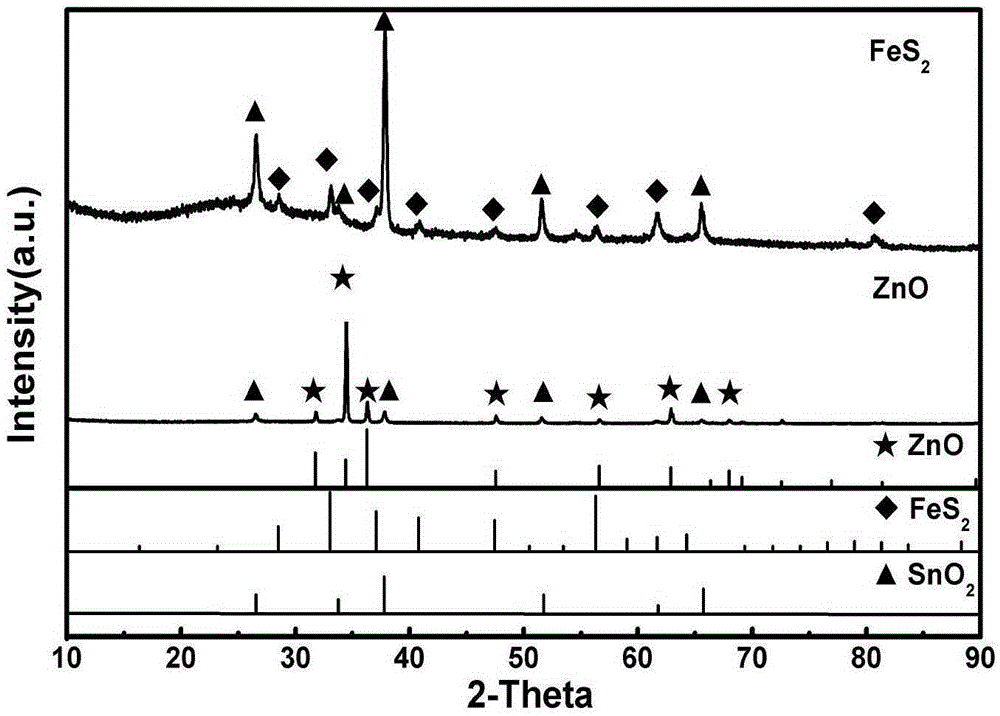

[0037] combined with Figure 1-4 , to further illustrate the present invention:

[0038] a FeS 2 The preparation method of thin film, comprises the following steps:

[0039] 1) Substrate pretreatment: In this example, the size is The conductive glass is used as the substrate, but the size of the substrate is not limited to the example of this embodiment. The substrate was ultrasonically cleaned in acetone solution for 20 minutes, then ultrasonically cleaned in absolute ethanol for 20 minutes, and finally ultrasonically cleaned in deionized water for 20 minutes; the cleaned substrate was dried in a constant temperature drying oven at 100°C, and the dried Base spare;

[0040] 2) Pour 50ml of ethylene glycol methyl ether solvent into a beaker, add 0.05mol of zinc acetate dihydrate and 3ml of ethanolamine, stir magnetically at a constant temperature of 60°C for 30min until completely dissolved, and form a uniform and transparent seed layer solution; magnetically stir The pur...

Embodiment 2

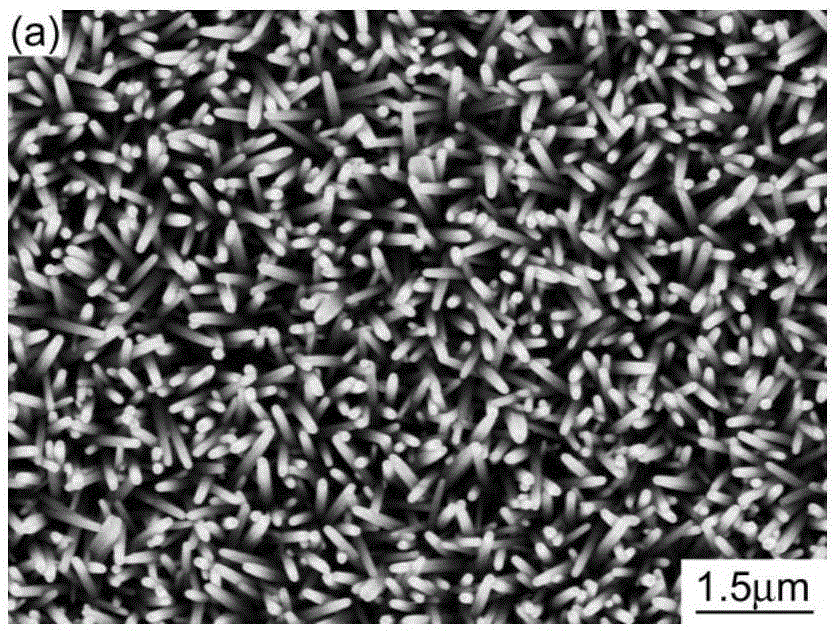

[0049] Such as Figure 4 , 5 As shown, a FeS 2 Thin film, including FTO conductive glass substrate 1, covered with FeS on the substrate 1 2 nanotube array, each FeS 2 Nanotube 2 made of FeS 2 The particles 21 are piled up.

[0050] by FeS 2 One-dimensional ordered FeS composed of nanoparticles 2 The nanotube array structure makes the FeS 2 The film has a three-dimensional structure, which enables the use of FeS 2 The inner and outer surfaces of the nanotubes undergo light absorption, greatly increasing the FeS 2 The light absorption area of the film; compared with conventional FeS 2 Nanoparticle films compared to one-dimensionally ordered FeS 2 Nanotube array structure has enhanced FeS 2 effective light absorption area of the film, increasing the FeS 2 The light-absorbing properties of thin films are improved by FeS 2 Advantages of thin-film photoelectric conversion efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com