Capacitive element, capacitor array, and a/d converter

A technology of capacitive elements and capacitors, applied in electrical components, tubular capacitors, analog-to-digital converters, etc., can solve problems such as increasing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

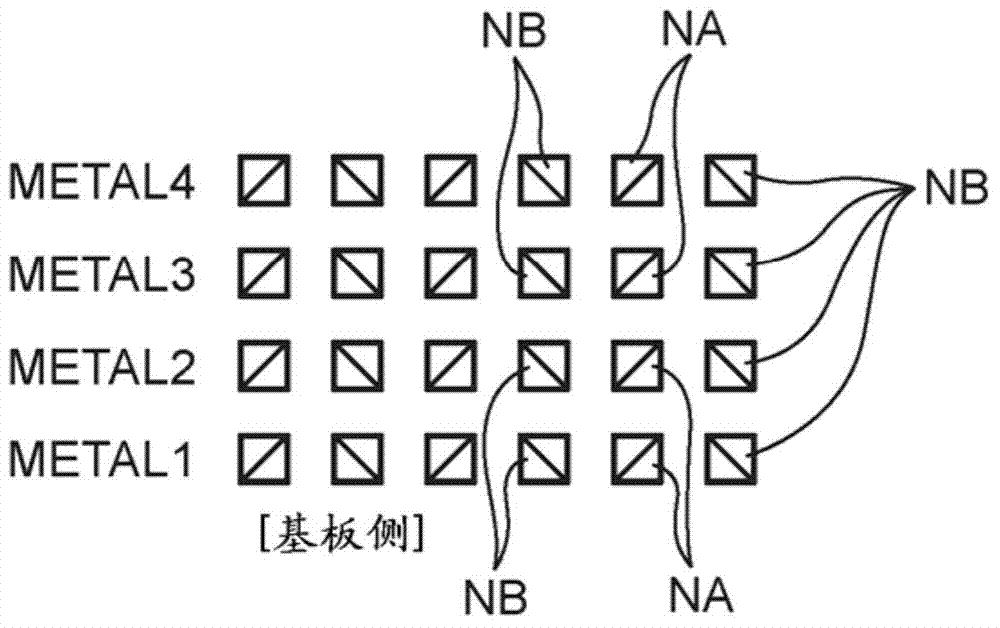

[0070] Before describing in detail embodiments of capacitive elements, capacitor arrays, and A / D converters, reference will be made to Figure 1A to Figure 5 Examples detailing capacitive elements, capacitor arrays, A / D converters and their problems.

[0071] Figure 1A with Figure 1B is a diagram showing an example of a comb-shaped capacitive element. Figure 1A shows a top view, and Figure 1B A cross-sectional view is shown. exist Figure 1A with Figure 1B , reference numeral NA denotes a first electrode (first node) of the capacitive element, NB denotes a second electrode (second node) of the capacitive element, and METAL1 to METAL4 denote respective layers of wiring layers (metal wiring layers).

[0072] In other words, if Figure 1A As shown, the first electrodes NA and the second electrodes NB are arranged alternately, and are capacitively coupled to each other to form a capacitive element (comb-shaped capacitive element). In addition, if Figure 1B As shown, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com