Automatic anti-dazzle electrochromic rearview mirror and manufacturing method thereof

An electrochromic and electrochromic material technology, applied in the field of rearview mirrors, can solve the problems of stimulating human eyes, troublesome use of rearview mirrors, and blindness of the eyes, so as to reduce mirror reflection, simple and feasible manufacturing process, and eliminate safety hazards. hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

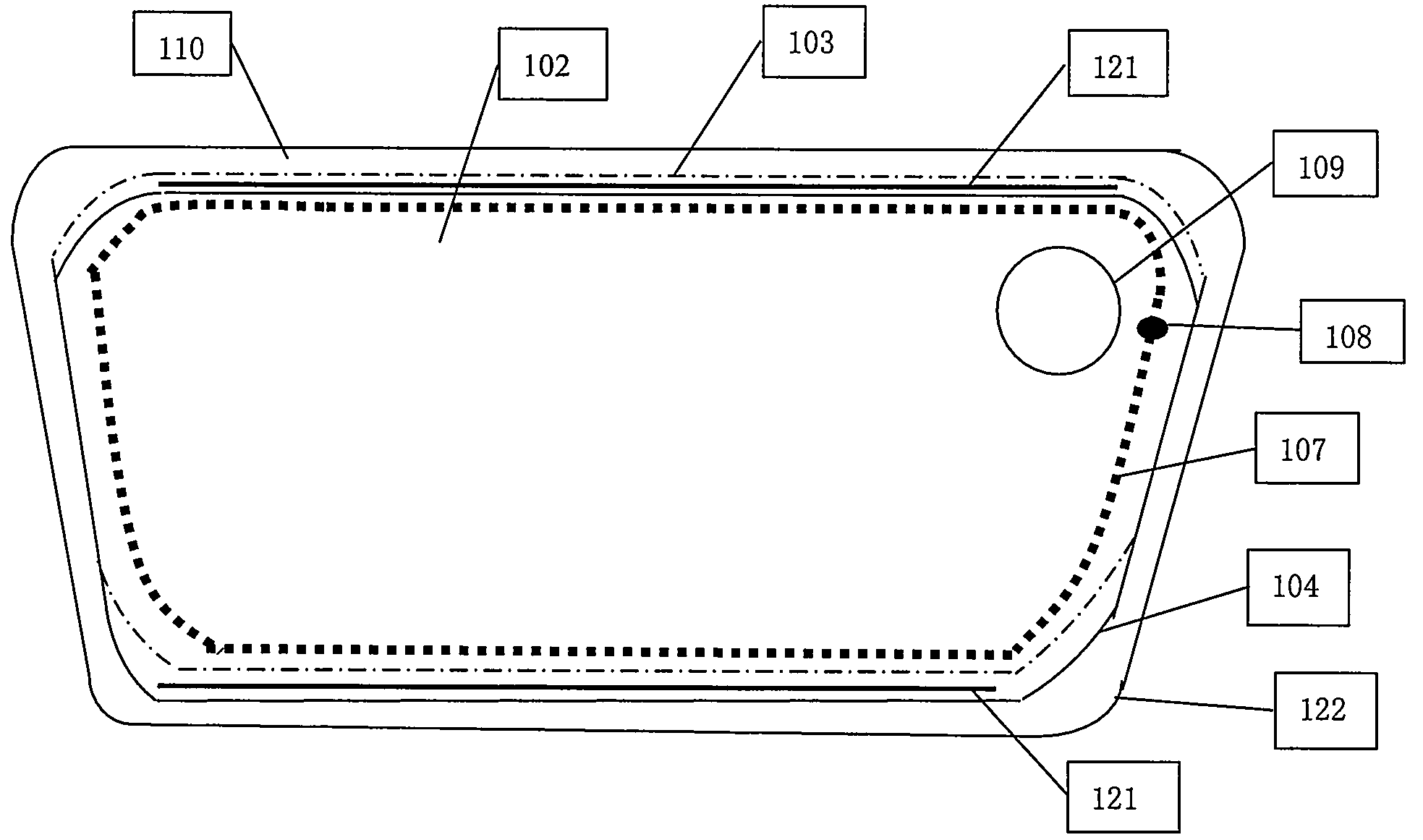

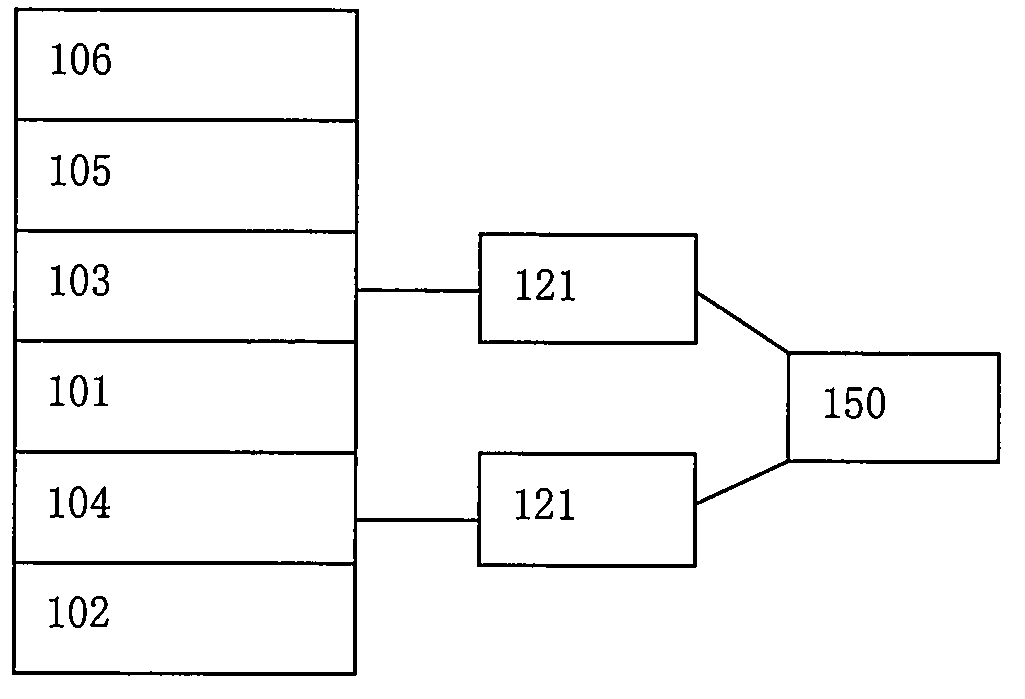

[0035] Such as image 3, first cut the IT0 glass with a thickness of 2mm and a square resistance of 10Ω into 2 pieces of trapezoidal glass with a long side of 260mm, a short side of 220mm, a width of 68mm, and four corners R=100mm, respectively as automatic anti-glare electric The cathode 103 and anode 104 substrates of the color-changing mirror; clean the cathode and anode substrates in an ultrasonic cleaning system; take them out, and then coat the conductive surfaces of the cathode and anode respectively at a position 2mm away from the surrounding edges. Adhesive with a width of 2.3mm Adhesive 107, forming an unclosed "C" shape, glass beads with a particle size of 20um are mixed in the adhesive, the conductive surfaces of the cathode 103 and the anode 104 are opposed, and pre-packaged to form a reserved filling port 208 The housing, the width of the reserved filling port 208 is 1mm; configure the electrochromic material system 101; in the vacuum environment of -0.05Pa, fill...

Embodiment 2

[0037] Such as Figure 5 , first cut the ZTO glass with a thickness of 0.2mm and a square resistance of 500Ω into two pieces of rectangular parallelepiped glass with a thickness of 280mm and a width of 66mm, respectively as the cathode 103 and anode 104 substrates of the automatic anti-glare electrochromic mirror; 1. The anode substrate is cleaned in an ultrasonic cleaning system; take it out, and then apply an adhesive 107 with a width of 0.1mm on the cathode conductive surface at a position 1.5mm away from the surrounding edge to form an open "C" shape, and bond Ceramic beads with a particle size of 2000um are mixed in the agent, and the conductive surfaces of the cathode 103 and the anode 104 are opposed to each other, and pre-packaged to form a shell with a reserved filling port 108, and the width of the reserved filling port 108 is 0.05mm ; configure the electrochromic material system 101; in a vacuum environment of -0.05Pa, fill the electrochromic material 101 into the p...

Embodiment 3

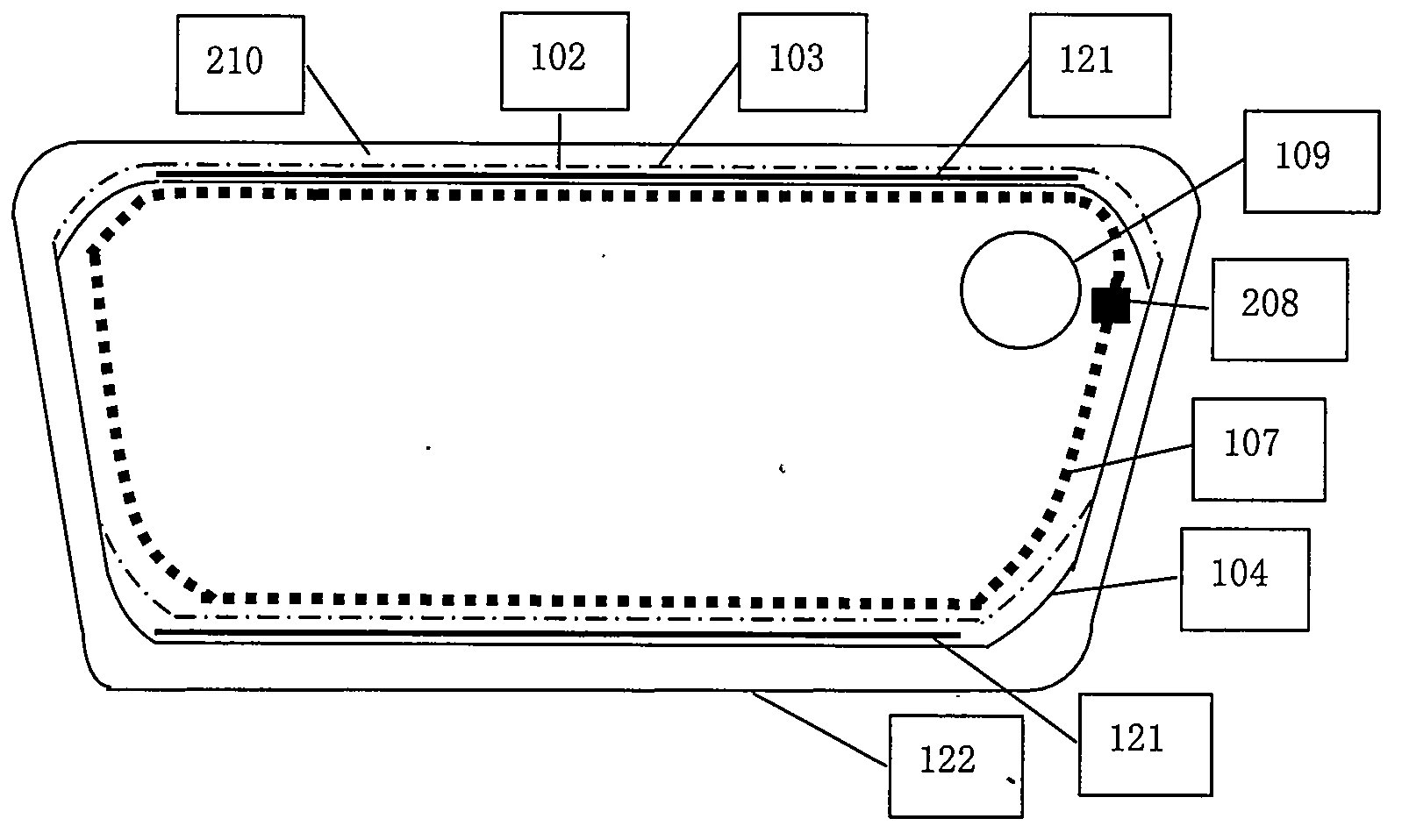

[0039] Such as Figure 7 Firstly, the ZTO glass with a thickness of 5mm and a square resistance of 5Ω is cut into two pieces of rectangular parallelepiped glass with a length of 350mm and a width of 75mm, respectively as the cathode 103 and the anode 104 substrate of the automatic anti-glare electrochromic mirror; 1. Clean the anode substrate in an ultrasonic cleaning system; take it out, and then apply an adhesive 107 with a width of 10mm on the conductive surface of the anode 104 at a position 0.5mm away from the surrounding edges to form an unclosed "C" shape. Metal material microbeads with a particle size of 2000um are mixed in the adhesive 107, and the conductive surfaces of the cathode 103 and the anode 104 are opposed to each other, and pre-packaged to form a shell with a reserved filling port 208, and the width of the filling port 208 is reserved 5mm; configure the electrochromic material system 101; in a vacuum environment of -0.05Pa, fill the electrochromic material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com