Multipoint compression high-temperature-resistant dynamic sealing device

A technology of high temperature resistance and dynamic sealing, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as unsatisfactory sealing effect, achieve radial flexible dynamic sealing, good high temperature resistance performance, and good market prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

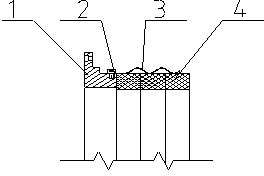

[0032] Embodiment 1 (emphasis illustrates the application of the present invention in the rotary kiln pyrolysis furnace)

[0033] A multi-point compression high-temperature resistant dynamic sealing device is applied in a rotary kiln pyrolysis furnace, where pyrolysis reaction occurs, the reaction temperature is 400°C-450°C, and at the same time, the temperature is 6-8 rad / min speed rotation.

[0034] The present invention seals between the two ends of the pyrolysis furnace of the rotary kiln and the fixed body 6, (the sealing surface of the rotating equipment and the inner contact surface of the graphite packing group are in flexible contact, when the outer surface of the rotating equipment is caused by processing When the roughness of the rotating equipment is uneven, it can also keep the sealing surface of the rotating equipment in good sealing contact with the inner contact surface of the graphite packing group, and can also ensure the normal rotation of the rotating equip...

Embodiment 2

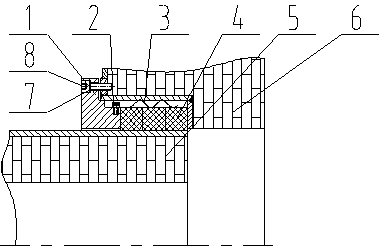

[0037] Embodiment 2 (focusing on the application of the present invention in the heating and stirring tank equipment of the sludge treatment system)

[0038] The reaction temperature in the heating and stirring tank is 400°C to 500°C, the tank body is a fixed body, and the drive shaft is a rotating device. The drive shaft rotates at a constant speed of 14-16 rad / min.

[0039] The invention seals between the drive shaft of the heating and stirring tank and the tank body, and the sealing surface of the drive shaft and the inner contact surface of the graphite packing group are in flexible contact. When the roughness of the outer surface of the drive shaft due to processing When it is uneven, it can also keep the sealing surface of the drive shaft in good sealing contact with the inner contact surface of the graphite packing group, and can also ensure the normal rotation of the drive shaft. The axial circumference of the sealing pressure ring 1 has a stepped circular hole, and a...

Embodiment 3

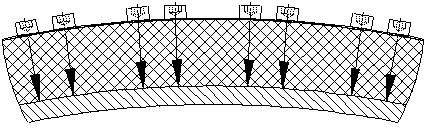

[0041] Embodiment 3 (focusing on the application of the present invention in the aggregate drying drum equipment in the asphalt mixing system)

[0042] The reaction temperature in the heating and stirring tank is 450°C to 480°C, the cylinder body is a rotating device, and the inlet and outlet cylinder covers on both sides of the cylinder are fixed bodies. The cylinder rotates at a constant speed of 7-9rad / min.

[0043] The invention seals the two ends of the aggregate drying cylinder and the inlet cylinder cover and the outlet cylinder cover, and the sealing surface of the cylinder body and the inner contact surface of the graphite packing group are in flexible contact. When the outer surface of the cylinder body is processed When the resulting roughness is uneven, it can also keep the sealing surface of the cylinder and the inner contact surface of the graphite packing group in good sealing contact, and can also ensure the normal rotation of the cylinder. The axial circumfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com