Zirconium-based alloy ingot and preparation method thereof as well as prepared zirconium-based amorphous alloy

A technology for zirconium-based alloys and alloy ingots, which is applied in the field of alloy ingots, and can solve the problems of unintroduced zirconium-based alloy ingot preparation methods and inability to obtain zirconium-based alloy ingots, etc., and achieve the effect of cooling speed suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

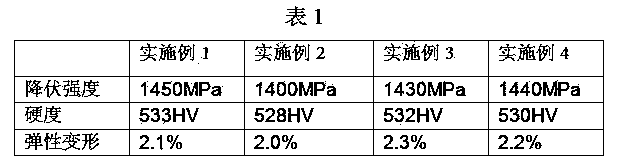

Examples

Embodiment 1

[0043] A zirconium-based alloy ingot, the zirconium-based alloy ingot is composed of the following atomic percent atoms:

[0044] Zr 65%

[0045] Cu 15%

[0046] Ni 8%

[0047] Al 9%

[0048] Nb 3%.

[0049] A method for preparing a zirconium-based alloy ingot, comprising the following steps:

[0050] Step A, preparation of the master alloy: Melting the Nb metal and part of the Ni metal required for the zirconium-based alloy ingot by vacuum arc melting method to obtain the master alloy. The preparation of the master alloy in the step A specifically includes the following steps:

[0051] Step A1, before melting: pump the melting chamber of the vacuum arc melting furnace to 10 -4 torr vacuum degree, then pour high-purity argon into the melting chamber, and the amount of high-purity argon is 60% of the volume of the melting chamber;

[0052]Step A2, during melting: mix the Nb metal and Ni metal required for the zirconium-based alloy ingot at a weight ratio of 51:49, and m...

Embodiment 2

[0062] A zirconium-based alloy ingot, the zirconium-based alloy ingot is composed of the following atomic percent atoms:

[0063] Zr 50%

[0064] Cu 20%

[0065] Ni 17%

[0066] Al 5%

[0067] Nb 8%.

[0068] A method for preparing a zirconium-based alloy ingot, comprising the following steps:

[0069] Step A, preparation of the master alloy: Melting the Nb metal and part of the Ni metal required for the zirconium-based alloy ingot by vacuum arc melting method to obtain the master alloy. The preparation of the master alloy in the step A specifically includes the following steps:

[0070] Step A1, before melting: pump the melting chamber of the vacuum arc melting furnace to 10 -4 torr vacuum, then pour high-purity argon into the melting chamber, the amount of high-purity argon is 80% of the volume of the melting chamber;

[0071] Step A2, when melting: mix the Nb metal and Ni metal required for the zirconium-based alloy ingot at a weight ratio of 51:49, and melt at a te...

Embodiment 3

[0081] A zirconium-based alloy ingot, the zirconium-based alloy ingot is composed of the following atomic percent atoms:

[0082] Zr 57%

[0083] Cu 15.4%

[0084] Ni 12.6%

[0085] Al 10%

[0086] Nb 5%.

[0087] A method for preparing a zirconium-based alloy ingot, comprising the following steps:

[0088] Step A, preparation of the master alloy: Melting the Nb metal and part of the Ni metal required for the zirconium-based alloy ingot by vacuum arc melting method to obtain the master alloy. The preparation of the master alloy in the step A specifically includes the following steps:

[0089] Step A1, before melting: pump the melting chamber of the vacuum arc melting furnace to 10 -4 torr vacuum degree, then pour high-purity argon into the melting chamber, and the amount of high-purity argon is 70% of the volume of the melting chamber;

[0090] Step A2, when melting: mix the Nb metal and Ni metal required by the zirconium-based alloy ingot at a weight ratio of 51:49, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com