Recycle hydrogen desulfurization system and method

A desulfurization system and a technology for circulating hydrogen, applied in the field of circulating hydrogen desulfurization system, can solve the problems of complex process, high energy consumption and high equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

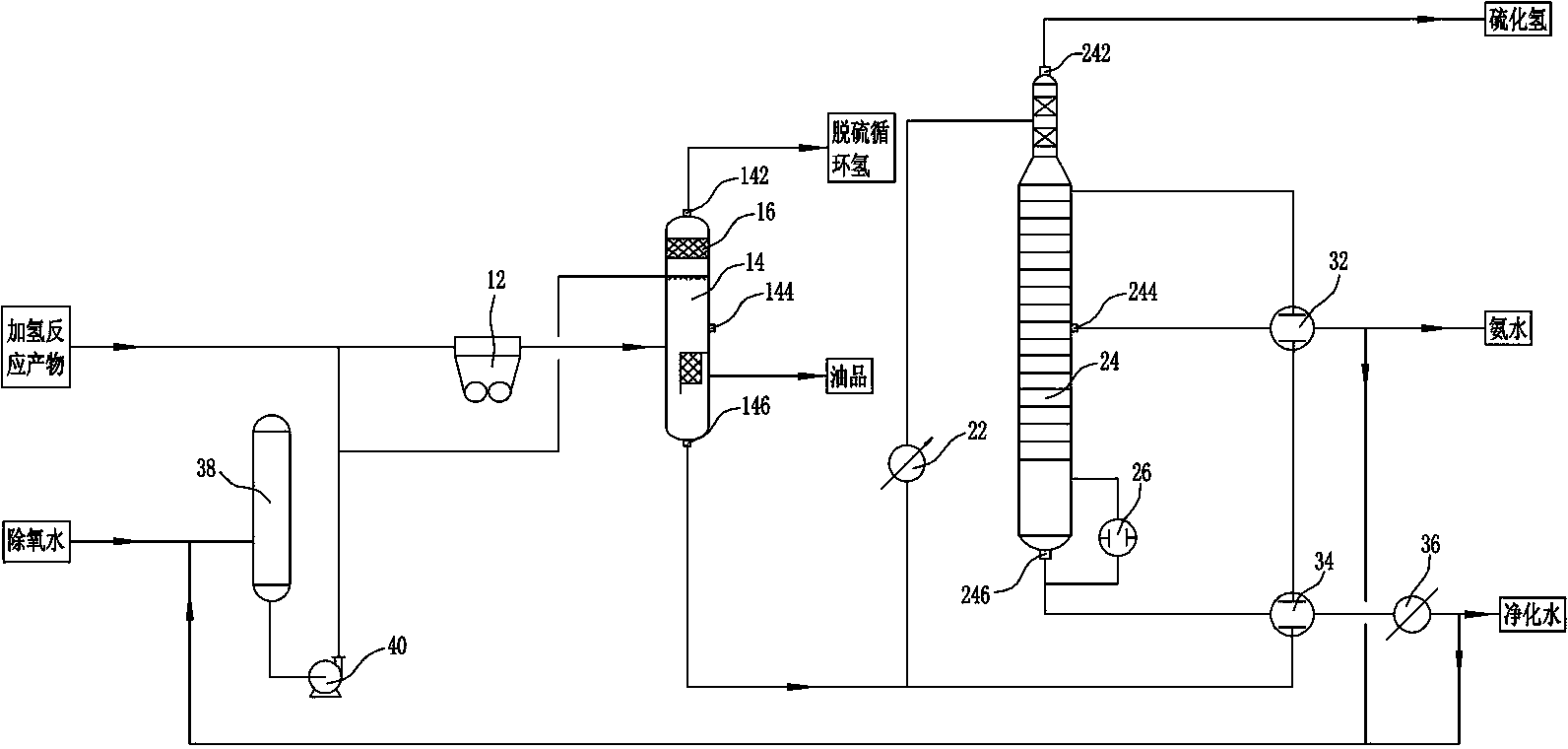

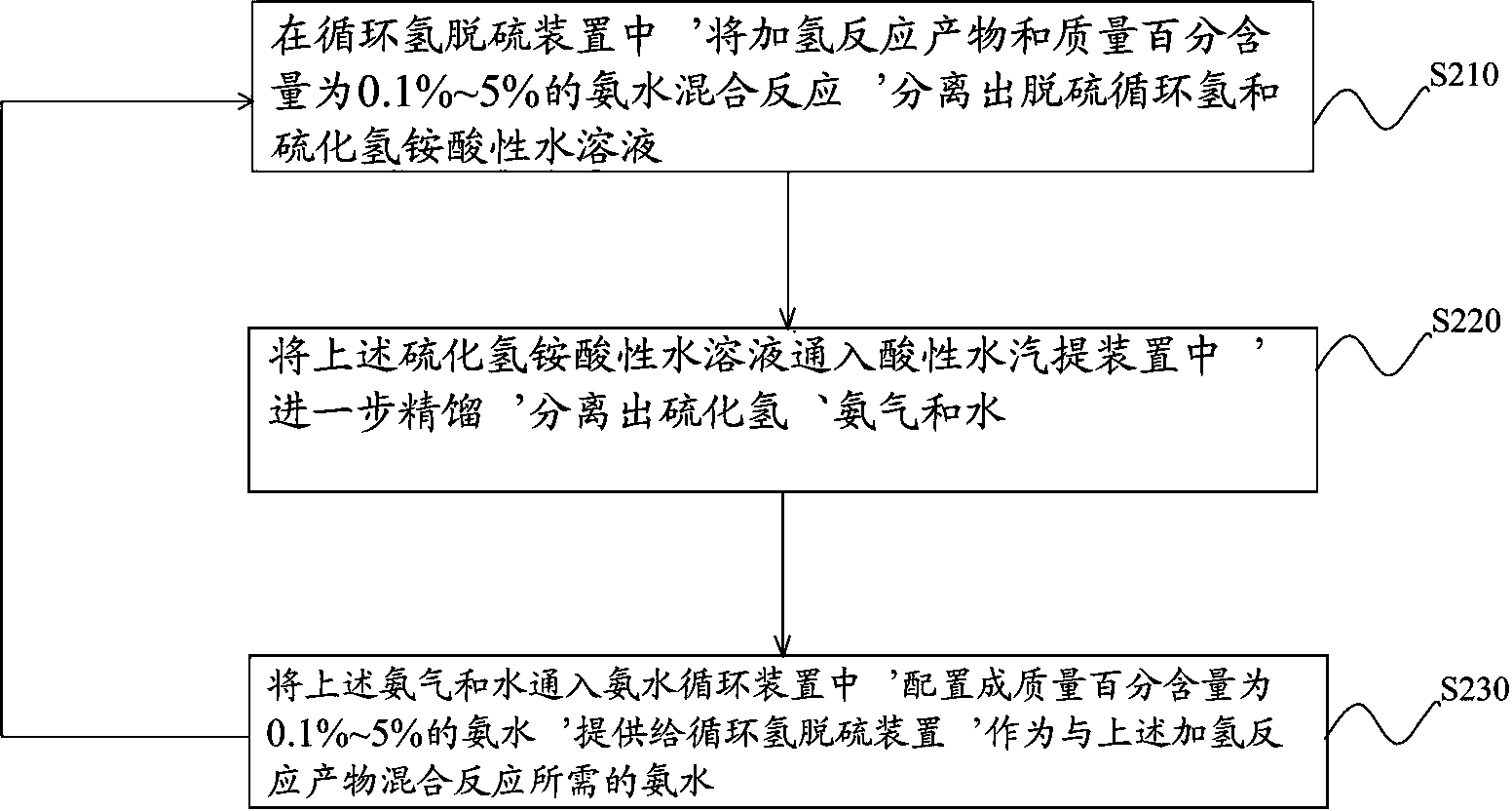

[0086] Mix the hydrogenation reaction product from the hydrogenation reaction with 1% (mass percentage) ammonia water and enter the air cooler to cool to 55°C, then send it to the cold high-pressure separator, and perform gas-liquid phase separation in the cold high-pressure separator , the top opening of the cold high-pressure separator discharges the desulfurization circulating hydrogen, the middle opening discharges the oil product, and the bottom opening discharges the acidic aqueous solution of ammonium hydrogen sulfide, in which the desulfurization circulating hydrogen contains H 2 S content <500ppm.

[0087] Pass the above-mentioned ammonium hydrogen sulfide acidic aqueous solution into the cold feed cooler to cool to 40°C, and transport it to the stripping tower. A reboiler is installed at the bottom of the stripping tower to provide heat source, and it is discharged from the top outlet of the stripping tower through rectification. Hydrogen sulfide, ammonia gas is disc...

Embodiment 2

[0091] Mix the hydrogenation reaction product from the hydrogenation reaction with 5% (mass percent) ammonia water and enter the air cooler to cool to 45°C, then transport it to the cold high-pressure separator, and perform gas-liquid phase separation in the cold high-pressure separator , the top opening of the cold high-pressure separator discharges the desulfurization circulating hydrogen, the middle opening discharges the oil product, and the bottom opening discharges the acidic ammonium hydrogen sulfide aqueous solution, in which the desulfurization circulating hydrogen contains H 2 S content <500ppm.

[0092] After passing the above-mentioned acidic ammonium hydrogen sulfide aqueous solution through the second heat exchanger and the first heat exchanger in turn for heat exchange, it is transported to the stripping tower, and a reboiler is provided at the bottom of the stripping tower to provide a heat source, and through rectification in the stripping tower Hydrogen sulfi...

Embodiment 3

[0096] Mix the hydrogenation reaction product from the hydrogenation reaction with 0.1% (mass percentage) ammonia water and enter the air cooler to cool to 50°C, then transport it to the cold high-pressure separator, and perform gas-liquid phase separation in the cold high-pressure separator , the top opening of the cold high-pressure separator discharges the desulfurization circulating hydrogen, the middle opening discharges the oil product, and the bottom opening discharges the acidic ammonium hydrogen sulfide aqueous solution, in which the desulfurization circulating hydrogen contains H 2 S content <500ppm.

[0097] Pass part of the above-mentioned ammonium hydrogen sulfide acidic aqueous solution into the cold feed cooler to cool to 40 ° C, and the other part passes through the second heat exchanger and the first heat exchanger in turn for heat exchange, and then transports it to the stripping tower, and the stripping tower A reboiler is provided at the bottom to provide a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com