Polyester dispersing agent and preparation method thereof

A dispersant and polyester technology, which is applied in the field of polyester dispersant and its preparation, can solve the problems of limited application range and narrow application range of solvent polarity, and achieve the effect of expanding application range and improving anchoring ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

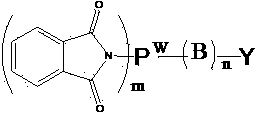

Image

Examples

example 1

[0019] 1) Dissolve 0.4 g of phthalic anhydride in 12 ml of xylene, and slowly drop it into a 250 ml three-necked flask containing 3 g of polyethyleneimine (molecular weight 1800, 99%), and react at 100 ℃ for 5 h 2) Add 40 g of caprolactone, 0.4 g of dibutyltin dilaurate, increase the temperature to 150 ℃ under the protection of nitrogen, and keep it for 6 hours; 3) Add 1.0 g of stearic acid, and react at 170 ℃ under reduced pressure Get the product in 3 h.

example 2

[0021] 1) Dissolve 0.5 g of phthalic anhydride in 20 ml of xylene, and slowly drop it into a 250 ml three-necked flask containing 8 g of polyethyleneimine aqueous solution (molecular weight 3600, 50%), and react at 110 ℃ 4 h and reflux to remove water; 2) Add 36 g of poly-12-hydroxystearic acid with an acid value of 24.5, raise the temperature to 160 ℃ under the protection of nitrogen, and use a water trap to remove the water generated by the reaction while the xylene is refluxed , Continue the reaction for 7 h; add 0.6 g of stearic acid and react at 180 ℃ for 2 h, then perform vacuum distillation at 160 ℃ until no obvious droplets flow out, and cool to obtain the product.

example 3

[0023] 1) Dissolve 0.2 g of phthalic anhydride in 15 ml of xylene, and slowly drop it into a 250 ml three-necked flask containing 3 g of polyethyleneimine (molecular weight 10,000, 99%), and react at 120 ℃ for 4 h Then, distill under reduced pressure to remove xylene; 2) Add 27.8 g of caprolactone, 14.5 g of poly-12-hydroxystearic acid with an acid value of 32.47, and 0.1 g of dibutyltin dilaurate, and raise the temperature to 155 under the protection of nitrogen. Keep it at ℃ for 6 h; 3) Add 1 g of stearic acid and react for 1.5 h at 175 ℃ under reduced pressure to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com