Preparation method of high-power ultraviolet intensity detection material

A technology of intensity detection and ultraviolet light, applied in the direction of photometry, luminescent materials, chemical instruments and methods, etc., can solve the problems of high cost, cumbersome detection methods, complicated equipment, etc., to reduce detection costs, save test time, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

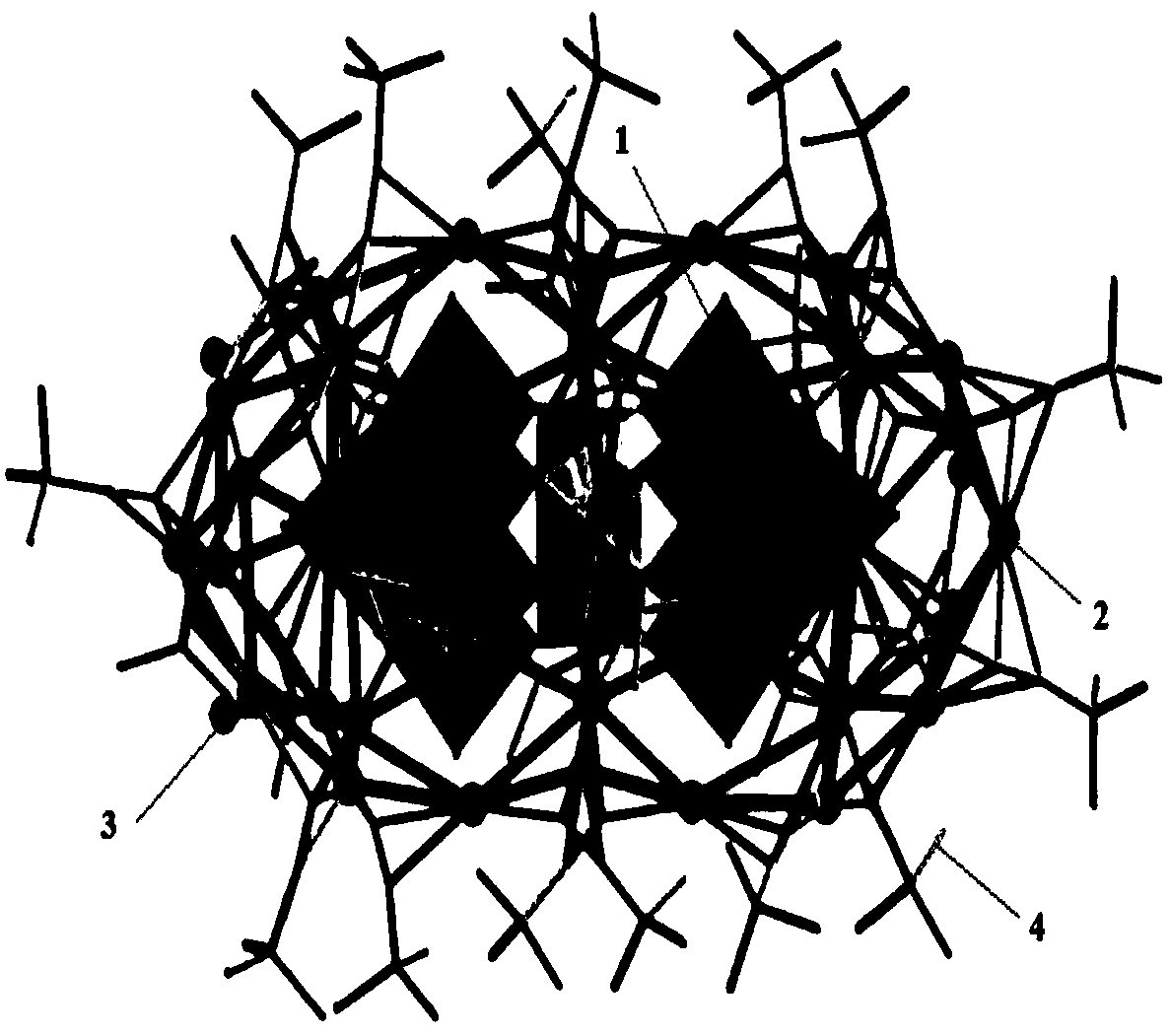

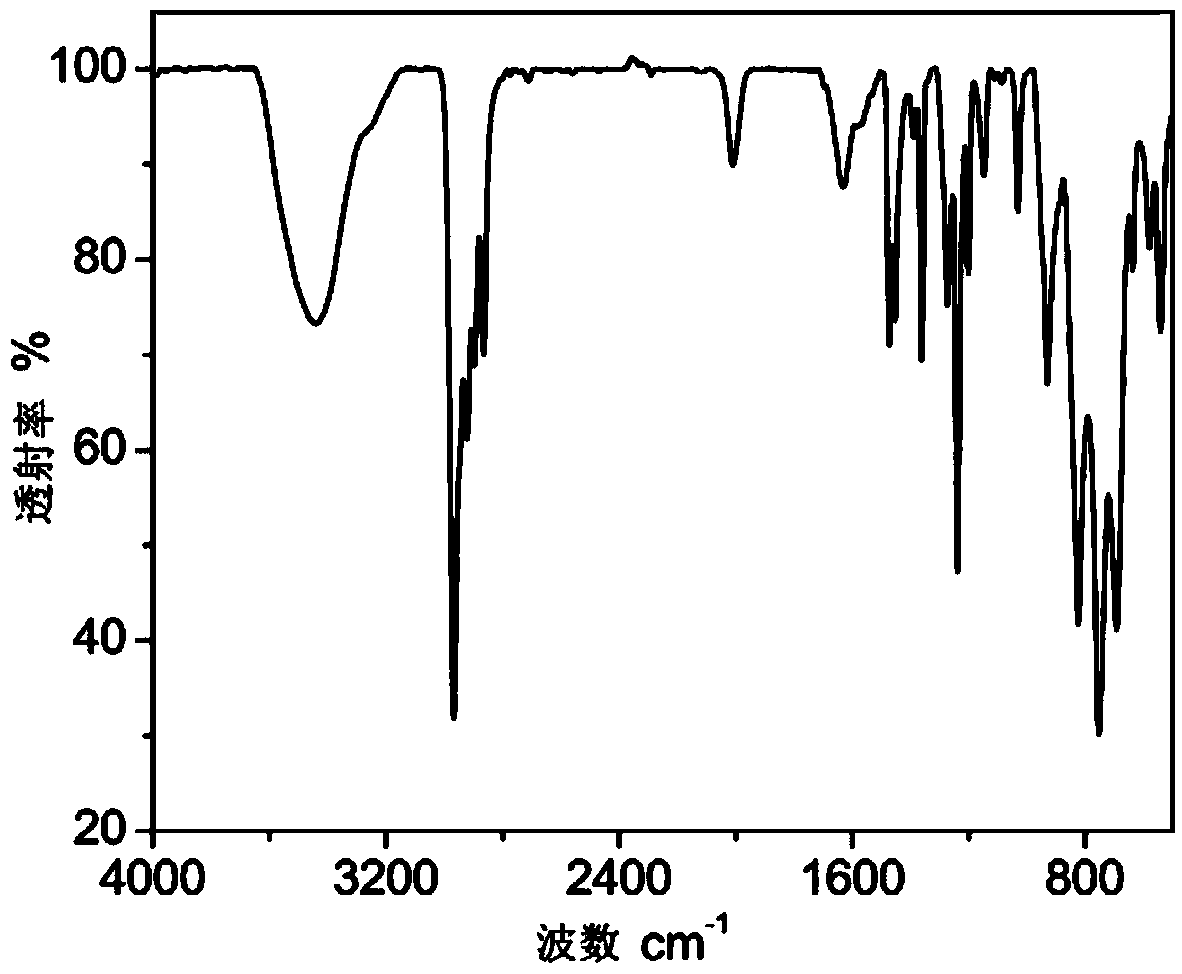

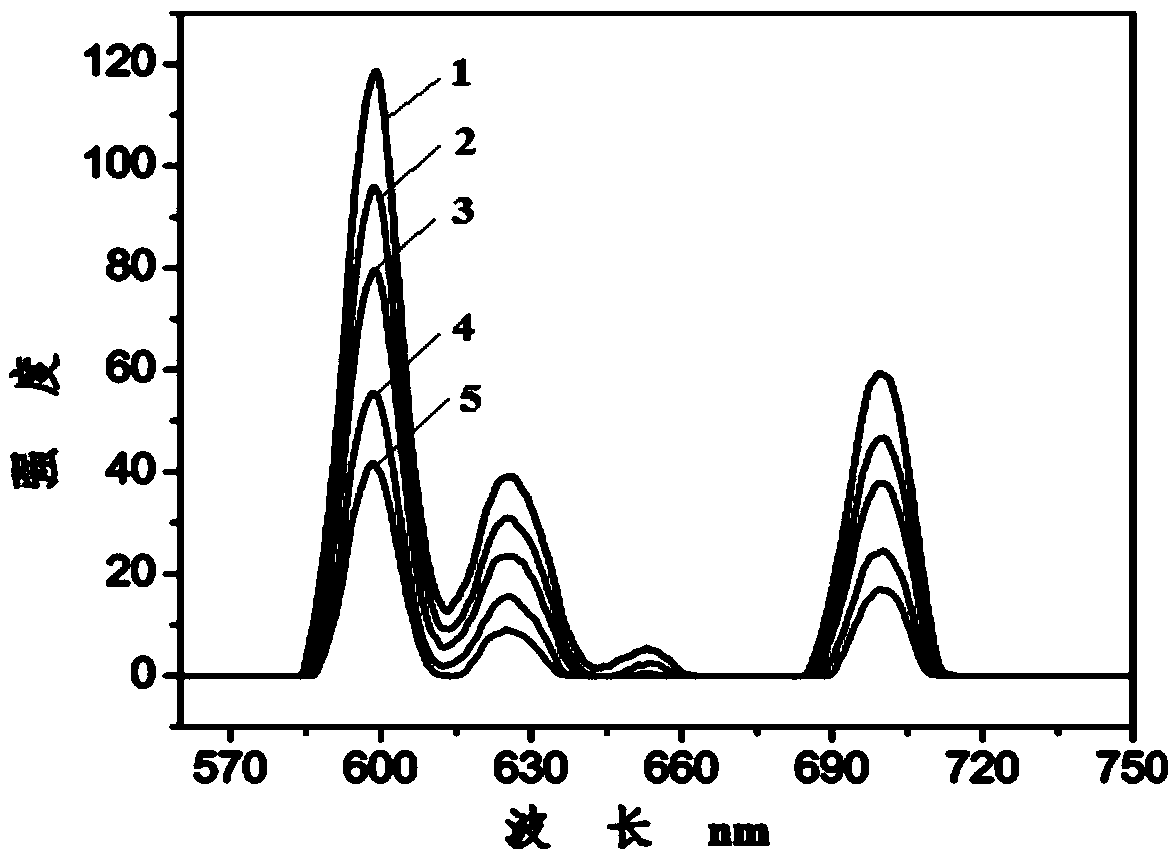

Image

Examples

specific Embodiment approach 1

[0024] Embodiment 1: A method for preparing a high-power ultraviolet intensity detection material in this embodiment is implemented according to the following steps:

[0025] Dissolve the silver-containing reactant in methanol, then add organic ligands, and stir for 20-50 minutes at a stirring speed of 150r / min-200r / min to obtain mixture A; then add rare earth-containing After polyoxometalates of elements and deionized water, stir for 30min to 45min at a stirring speed of 300r / min to 400r / min to obtain mixture B; then transfer mixture B to a hydrothermal kettle, After reacting at 120°C for 72 hours, then cool to room temperature, and after filtration, place the obtained filtrate at room temperature for 20d to 25d to obtain the ultraviolet intensity detection material, that is, the preparation of the high-power ultraviolet intensity detection material is completed;

[0026] Wherein, the reactant containing silver element is composed of one or more of silver nitrate, silver acet...

specific Embodiment approach 2

[0035] Specific embodiment two: The difference between this embodiment and specific embodiment one is that the reactant containing silver element is composed of silver nitrate and silver acetate in a ratio of 1:2 according to the amount of substance, and the multiple The oxometalate is Na 9 wxya 10 o 32 . Others are the same as the first embodiment.

specific Embodiment approach 3

[0036] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the reactant containing silver element is composed of silver nitrate and silver trifluoroacetate in a ratio of 1:2 according to the amount of substance, The polyoxometalates containing rare earth elements are K 9 wxya 10 o 36 . Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com