Method for continuously producing dimethyl disulfide

A technology of dimethyl disulfide and dimethyl trisulfide, which is applied in the field of petroleum fine chemical industry and can solve problems such as difficult recovery of methyl mercaptan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

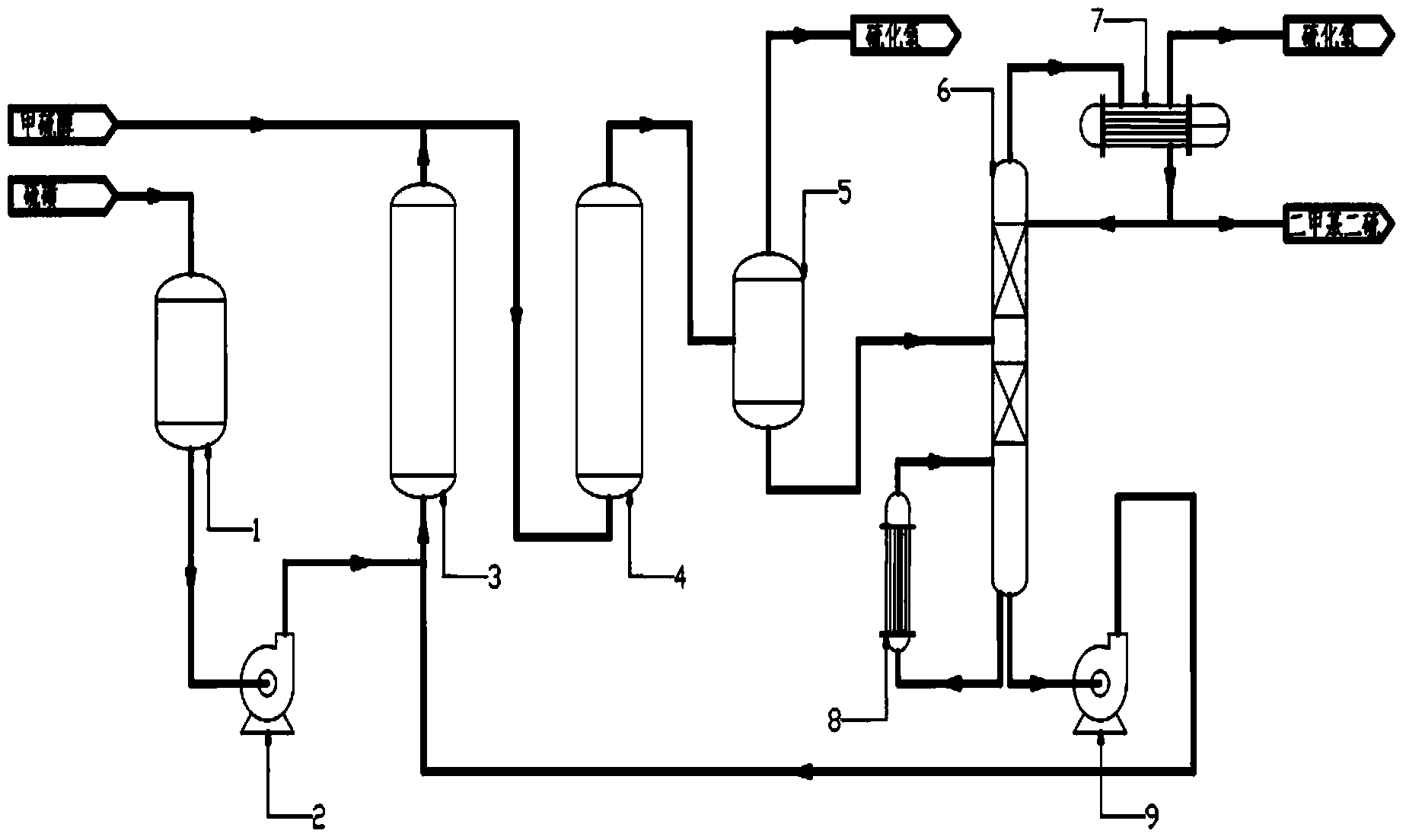

Method used

Image

Examples

Embodiment 1

[0030] 433.2kg / h sulfur is melted and pumped to a tubular reactor with a diameter of 1m and a length of 10m, made of 304 stainless steel, and circulating 2999.9kg / h dimethyl disulfide (88.5wt% dimethyl disulfide, Dimethyl trisulfide 11.5wt%) mixed, by adjusting the circulating flow rate of dimethyl disulfide to control the reactor inlet temperature is 20 ℃, the stoichiometric ratio of dimethyl disulfide and sulfur (calculated as sulfur element) is 2.1, The reaction pressure is 0.2MPaA, the outlet temperature of the reactor is 30°C, the excess dimethyl disulfide makes the sulfur completely converted, and basically no dimethyl polysulfide is generated during the reaction.

[0031] 3433.1kg / h of reaction products (40.3wt% dimethyl disulfide and 59.7wt% dimethyl trisulfide) are mixed with 1298.9kg / h methyl mercaptan, and enter a tubular reactor with a diameter of 1.2m and a length of 12m , The material is 304 stainless steel, the stoichiometric ratio of dimethyl trisulfide to meth...

Embodiment 2

[0035] 434.2kg / h sulfur is melted and pumped to a tubular reactor with a diameter of 1m and a length of 10m, made of 304 stainless steel, and circulating 4500.3kg / h dimethyl disulfide (composed of dimethyl disulfide 75.9wt%, Dimethyl trisulfide 24.1wt%) mixed, by adjusting the circulating flow rate of dimethyl disulfide to control the reactor inlet temperature is 30 ℃, the stoichiometric ratio of dimethyl disulfide and sulfur (calculated as sulfur element) is 2.7, The reaction pressure is 0.4MPaA, the outlet temperature of the reactor is 35°C, the excess dimethyl disulfide makes the sulfur completely converted, and basically no dimethyl polysulfide is generated during the reaction.

[0036] 4934.5kg / h of reaction products (43.4wt% dimethyl disulfide and 56.6wt% dimethyl trisulfide) are mixed with 1298.9kg / h methyl mercaptan, and enter a tubular reactor with a diameter of 1.2m and a length of 12m , The material is 304 stainless steel, the stoichiometric ratio of dimethyl trisul...

Embodiment 3

[0040] 433.7kg / h of sulfur is melted and pumped to a tubular reactor with a diameter of 1m and a length of 10m, made of 304 stainless steel, and circulating 5000.3kg / h dimethyl disulfide (87.1wt% dimethyl disulfide, Dimethyl trisulfide 12.9wt%) mixed, by adjusting the circulating flow rate of dimethyl disulfide to control the reactor inlet temperature is 35 ° C, the stoichiometric ratio of dimethyl disulfide and sulfur (calculated as sulfur element) is 3.4, The reaction pressure is 0.6MPaA, the outlet temperature of the reactor is 40°C, the excess dimethyl disulfide makes the sulfur completely converted, and basically no dimethyl polysulfide is generated during the reaction.

[0041] 5434kg / h of reaction products (56.7wt% dimethyl disulfide and 43.3wt% dimethyl trisulfide) are mixed with 1298.9kg / h methyl mercaptan, and enter a tubular reactor with a diameter of 1.2m and a length of 12m. The material is 304 stainless steel, the stoichiometric ratio of dimethyl trisulfide to me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com