Sequencing batch reactor, method for culturing biological membrane on sequencing batch reactor and method for treating sewage by utilizing sequencing batch reactor

A sequencing batch reactor and the technology of the reactor are applied in the field of culturing biofilms in the reactor and sequencing batch reactors, which can solve the problems of complicated control of the reactor, and achieve compact structure, small diameter, nitrogen, phosphorus and organic matter. low content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

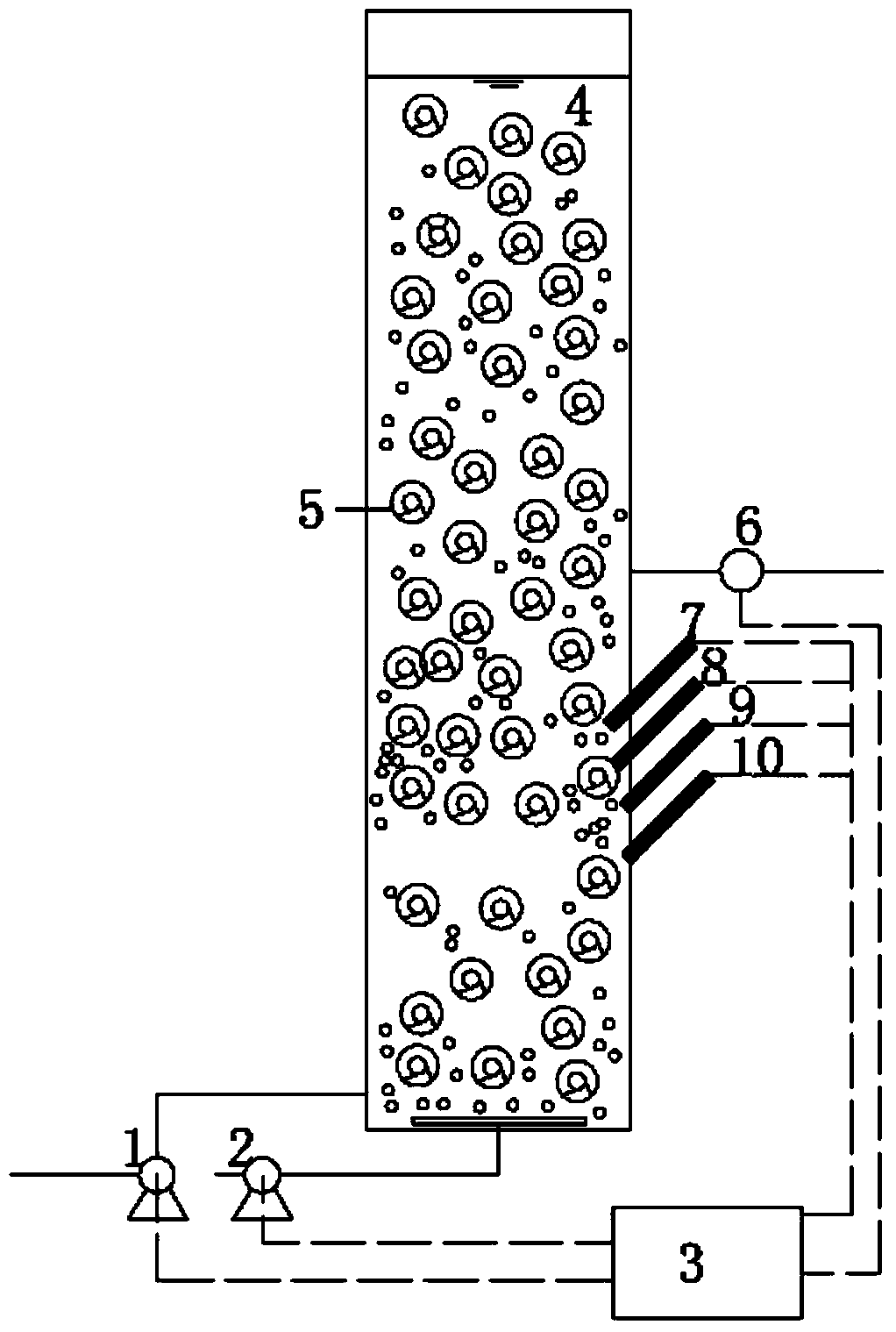

[0026] Such as figure 1 As shown, the sequencing batch reactor of this embodiment includes a reactor body 4 with an effective volume of 4L, an inlet pump 1, an inlet pump 2, a control system 3, a packing 5, a drain valve 6 and a dissolved oxygen concentration detector 7, A nitrate concentration detector 8, an organic matter concentration detector 9, and a phosphate concentration detector 10, the inlet pump 1, the inlet pump 2, and the drain valve 6 are connected to the reactor body 4 respectively, and the control system 3 analyzes dissolved oxygen The signals of the concentration detector 7, the nitrate concentration detector 8, the organic matter concentration detector 9 and the phosphate concentration detector 10 adjust the working conditions of the water inlet pump 1, the inlet pump 2 and the drain valve 6, and the diameter of the filler 5 is 3cm. The specific surface area is 200m 2 / m 3 , its volume is 80% of the reactor body 4.

[0027] As an improvement of the sequenc...

Embodiment 2

[0043] The difference between the sequencing batch reactor of this embodiment and embodiment 1 is that in this embodiment, the filler 5 has a diameter of 5 cm and a specific surface area of 220 m 2 / m 3 , whose volume is 50% of the reactor body 4. In the batch reactor of this embodiment, the filler 5 is made by 3D printing method, and its shape is a three-dimensional honeycomb spherical shape with 35 planes, and the material is polyamide fiber .

[0044] In the present embodiment, the method for cultivating biofilm in the sequencing batch reactor comprises the following steps:

[0045] 1) Select the sequencing batch reactor and inoculate with aerobic activated sludge, the concentration of the inoculated sludge is 3g / L;

[0046] 2) Under the anaerobic state, pump sewage containing organic matter and nitrogen and phosphorus into the reactor. The pH of the sewage is 7.5, the temperature is 8°C, and the water injection time is 60 minutes. The anaerobic state refers to the sewa...

Embodiment 3

[0059] The difference between the sequencing batch reactor of this embodiment and embodiment 1 is that in this embodiment, the filler 5 has a diameter of 2 cm and a specific surface area of 250 m 2 / m 3 , whose volume is 35% of the reactor body 4. In the batch reactor of this embodiment, the filler 5 is made by 3D printing method, and its shape is a three-dimensional honeycomb spherical shape with 40 planes, and the material is polyamide fiber .

[0060] In the present embodiment, the method for cultivating biofilm in the sequencing batch reactor comprises the following steps:

[0061] 1), select the sequencing batch reactor and inoculate aerobic activated sludge, the concentration of the inoculated sludge is 2g / L;

[0062] 2) Under the anaerobic state, pump sewage containing organic matter and nitrogen and phosphorus into the reactor. The pH of the sewage introduced is 6.5, the temperature is 25°C, and the water injection time is 45 minutes. The anaerobic state refers to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com