Liquid crystal screen protective film and preparation method thereof

A technology of screen protective film and protective film, which is applied in the direction of chemical instruments and methods, instruments, and layered products. The bonding process is cumbersome, the printing effect is full, and the effect of easy bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

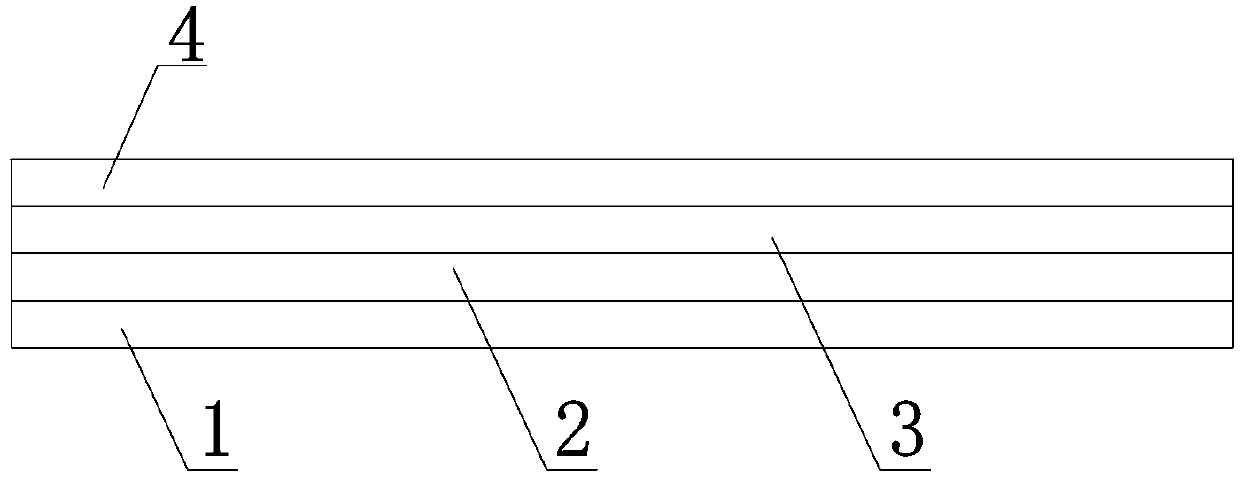

[0026] The thickness of the white PET film is 0.03mm, the thickness of the transparent double-sided adhesive layer is 0.03mm, and the thickness of the PE film is 0.0475mm.

Embodiment 2

[0028] The thickness of the white PET film is 0.07mm, the thickness of the transparent double-sided adhesive layer is 0.07mm, and the thickness of the PE film is 0.0725mm.

Embodiment 3

[0030] The thickness of the white PET film is 0.05mm, the thickness of the transparent double-sided adhesive layer is 0.05mm, and the thickness of the PE film is 0.06mm.

[0031] The liquid crystal screen protective film of the present invention, because the screen display part does not contain any adhesive components, such as glue, only the non-display window area is glued for bonding with the screen, and no air bubbles will be generated when it is in contact with the screen, so it is very easy to bond ; The edge decoration part uses the color of the raw material itself as the background color, the printing effect is fuller and the color is more gorgeous. It can be applied to LCD screen protection films and decorative products of various high-end smart phones, handheld computers, tablet computers and other digital products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com