A new numerical control wire electric discharge cutting method and device

A technology of electric discharge wire and cutting device, which is applied in the direction of electrode manufacturing, electric processing equipment, metal processing equipment, etc., can solve the problems of increasing the secondary clamping process, positioning error, etc., achieve convenient processing operation, reduce costs, and improve processing The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

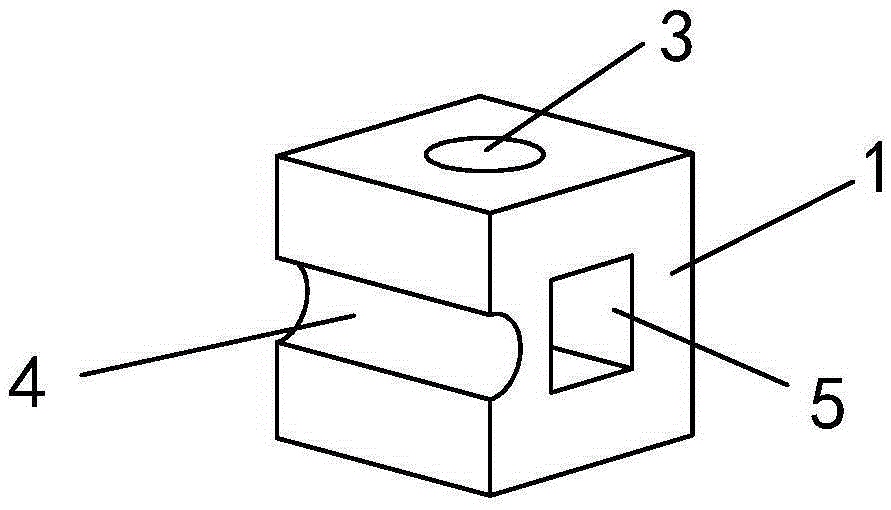

[0052] Embodiment one: see Figure 4 Shown:

[0053] A new type of CNC wire-cutting method, designing and developing a reciprocating wire-cutting (commonly known as fast wire) CNC wire-cutting device, the CNC wire-cutting device is equipped with at least a CNC X-axis, a CNC Y-axis and a CNC Z-axis shaft, and the wire electrode 2 for discharge cutting in its wire-feeding system is provided with a horizontal cutting section 6 and a vertical cutting section 7 . The horizontal cutting section 6 is formed by supporting the electrode wire 2 through a guide wheel 8. In the initial state, the electrode wire in the horizontal cutting section 6 is in a horizontal plane and parallel to the X axis; the vertical cutting section 7 is formed by The electrode wire 2 is formed by being supported by guide wheels 8. In an initial state, the electrode wire in the vertical cutting section 7 is in a vertical plane and parallel to the Z axis. The horizontal cutting section 6 and the vertical cutti...

Embodiment 2

[0057] Embodiment two: see Figure 5 Shown:

[0058] A new CNC wire electric discharge method, design and development of a reciprocating wire electric discharge (commonly known as fast wire) CNC wire electric discharge device, the difference from the first embodiment is: in the initial state, the horizontal cutting section 6 The electrode wire is in the horizontal plane and parallel to the Y axis; when the workpiece 1 is clamped once, when the workpiece 1 is processed by the vertical cutting section 7, the workpiece 1 is cut through the linkage of the numerically controlled X axis and the numerically controlled Y axis A ruled surface around the Z axis; when using the horizontal cutting section 6 to process the workpiece 1, the ruled surface on the workpiece around the Y axis is cut through the linkage of the numerically controlled X axis and the numerically controlled Z axis. The ruled surface around the Y axis is a through hole 5 along the horizontal direction.

[0059] Oth...

Embodiment 3

[0060] Embodiment three: see Image 6 Shown:

[0061] A new numerically controlled wire electric discharge method, the difference from the first embodiment is that it is a numerically controlled wire electric discharge device with one-way wire walking (commonly known as slow wire) designed and developed, and the horizontal cutting section 6 Both the vertical cutting section 7 and the vertical cutting section 7 are formed by the support of the electrode wire 2 through the guide 9, and the electrode wire 2 runs unidirectionally along its own axial direction.

[0062] Others are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com