A continuous casting tundish breathable upper nozzle seat brick and its installation method

A technology for continuous casting tundish and nozzle seat bricks, which is applied in casting equipment, casting molten material containers, metal processing equipment, etc., and can solve problems such as poor production and application effects, no capture, removal of inclusions, and increased resistance, and achieve Facilitates flotation and removal, eases over-eye problems, and eases the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

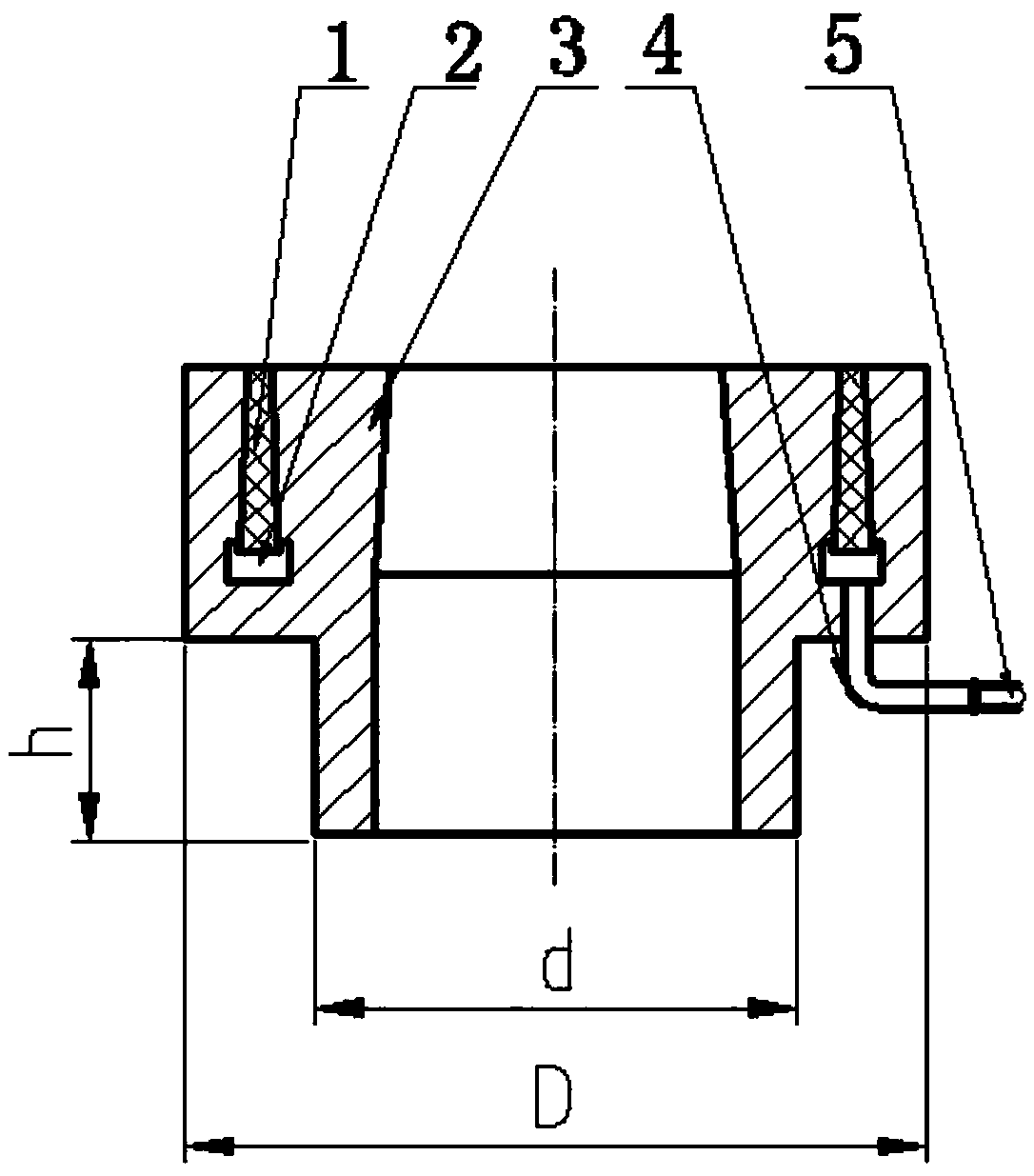

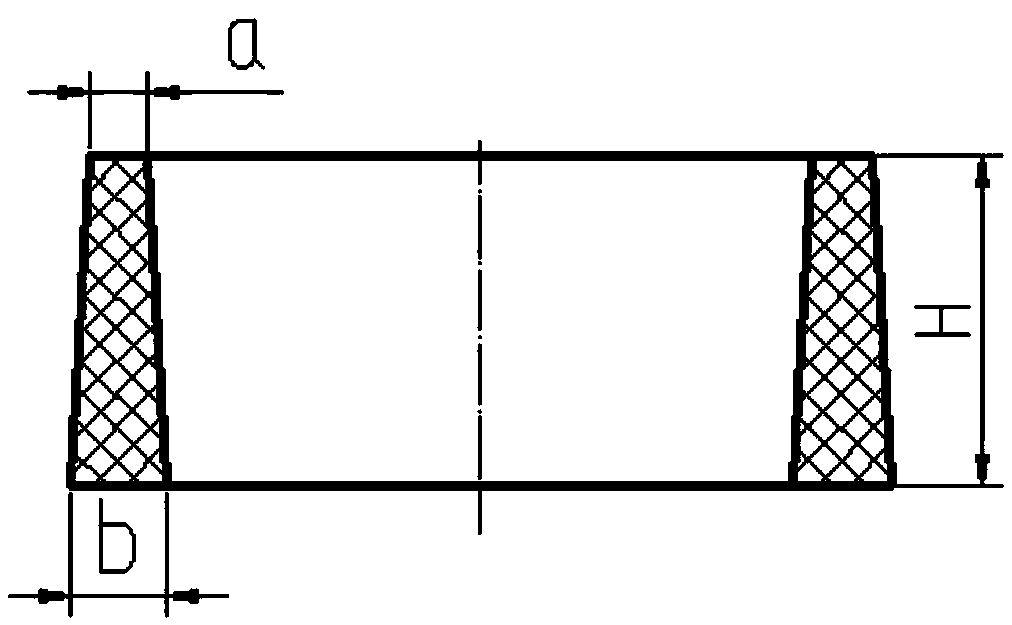

[0057] A continuous casting tundish breathable upper nozzle seat brick, such as figure 1 , figure 2 , image 3 As shown, including the upper nozzle block body 3, the upper nozzle block body 3 is casted with corundum castable, the refractoriness of the corundum castable is ≥1790°C, and the bulk density is ≥2.9g / cm 3 , normal temperature compressive strength ≥ 80Mpa, Al in corundum castable 2 o 3 Content ≥ 93%, the middle part of the upper nozzle block body is provided with an upper nozzle installation hole that penetrates up and down, and the upper nozzle block body 3 is provided with a circular breathable ring 1 and an annular air chamber box 2, the air chamber box 2 Located at the bottom of the breathable ring 1 and communicated with the breathable ring 1, the bottom of the air chamber box 2 is connected with an air intake pipe 4, and the upper nozzle block body 3 includes an integrally formed upper boss and a lower boss, and the outer diameter of the lower boss is less t...

Embodiment 2

[0060] The continuous casting tundish breathable upper nozzle block as described in Example 1, the difference lies in:

[0061] The upper ring width a of the breathable ring 1 is 25 mm, the lower ring width b is 7 mm larger than the upper ring width a, and the height H of the breathable ring 1 is 90 mm.

[0062] The air chamber box 2 is circular as a whole, and the inner air chamber is integrally formed by a metal box. The cross section of the metal box is rectangular, the width m of the rectangle is 35mm, and the height n is 20mm.

[0063] The outer diameter D of the upper boss of the upper nozzle block body 3 is 380mm, the outer diameter d of the lower boss is 300mm, and the height h of the lower boss is 100mm. The upper end of the boss on the upper nozzle block body 3 is 10mm higher than the upper surface Z of the working lining 15 at the bottom of the tundish.

Embodiment 3

[0065] The continuous casting tundish breathable upper nozzle block as described in Example 1, the difference lies in:

[0066] The upper ring width a of the breathable ring 1 is 23 mm, the lower ring width b is 6 mm larger than the upper ring width a, and the height H of the breathable ring 1 is 75 mm.

[0067] The air chamber box 2 is in the shape of a ring as a whole, and the inner air chamber is formed integrally with a metal box. The cross section of the metal box is rectangular, the width m of the rectangle is 30mm, and the height n is 18mm.

[0068]The outer diameter D of the upper boss of the upper nozzle block body 3 is 370 mm, the outer diameter d of the lower boss is 290 mm, and the height h of the lower boss is 120 mm. The upper end of the boss on the upper nozzle block body 3 is 8mm higher than the upper surface Z of the working lining 15 at the bottom of the tundish.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com