Alginate fibre metal complex photocatalyst and preparation method thereof

A metal complex, seaweed fiber technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of not easily biodegradable synthetic fibers, catalyst preparation process Complications, unfavorable protection of the ecological environment, etc., achieve the effects of excellent repeated use performance, conducive to industrialization, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Pretreatment process: at room temperature and under stirring conditions, first use a non-ionic surfactant aqueous solution with a concentration of 2.0g / L to wash and treat the seaweed fiber for 10 minutes, then take it out, then use distilled water to wash it 5 times, and finally put the It can be dried under vacuum at 50°C;

[0034] 2. Preparation of iron-copper metal ion mixed solution: use copper sulfate and ferric chloride to prepare a mixed metal ion aqueous solution with a molar concentration of 0.10 mol / L, and the molar concentration ratio of iron ions and copper ions in the mixed aqueous solution is required to be 1: 0.33, that is, the volume concentration of ferric chloride aqueous solution and copper sulfate aqueous solution is 0.075mol / L and 0.025mol / L respectively. Then the resulting mixed aqueous solution was left to stand for 2-5 hours, and filtered for subsequent use;

[0035] 3. Coordination reaction between seaweed fiber and metal ion: the seaweed f...

Embodiment 2

[0039] 1. The process is the same as Step 1 in Example 1 respectively.

[0040] 2. The molar concentration ratio of iron ion and copper ion in the mixed aqueous solution of metal ions is adjusted to 1: 1, that is, the volume concentration of ferric chloride aqueous solution and copper sulfate aqueous solution is 0.05mol / L and 0.05mol / L respectively. All the other are with 2 in embodiment 1.

[0041] 3. The process is the same as step 3 in Example 1 respectively.

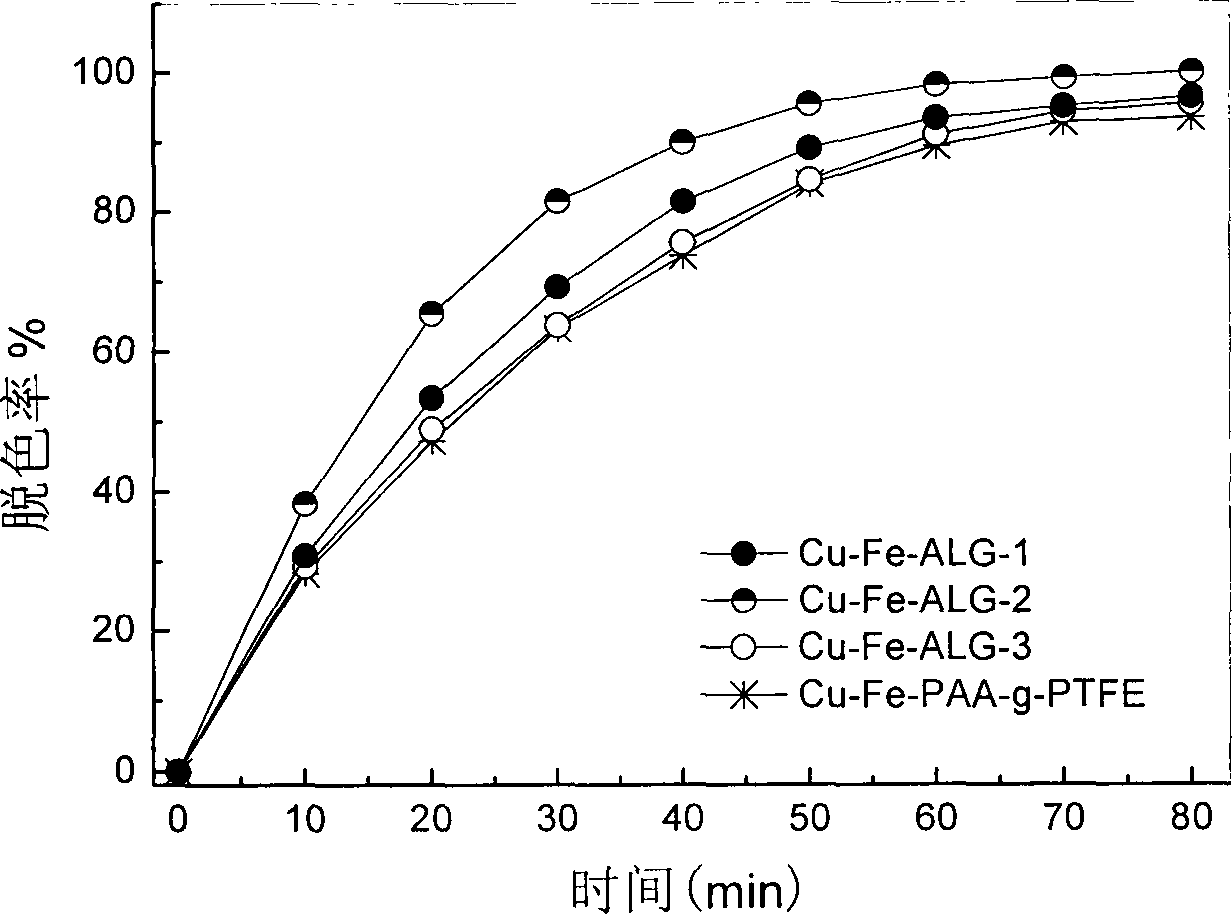

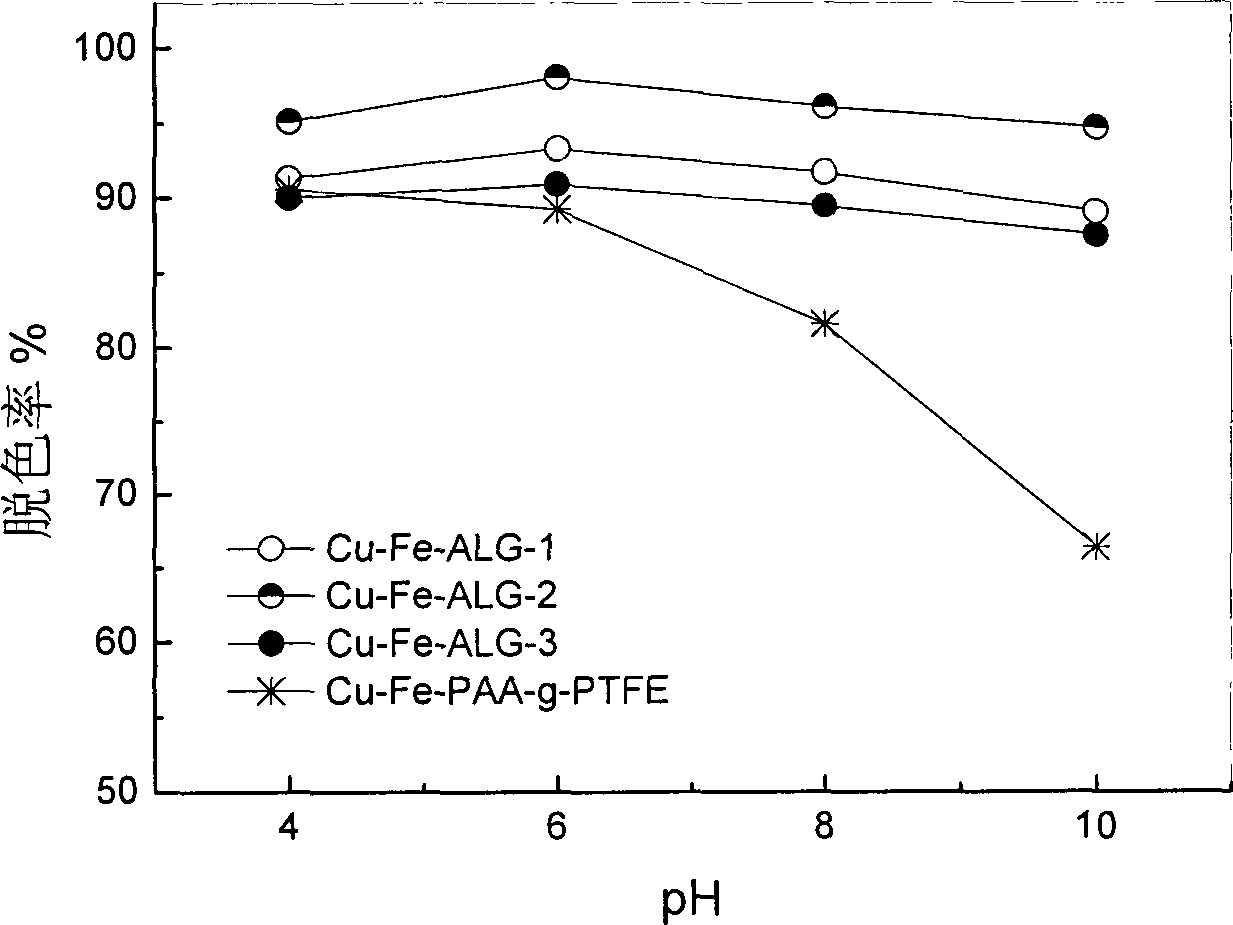

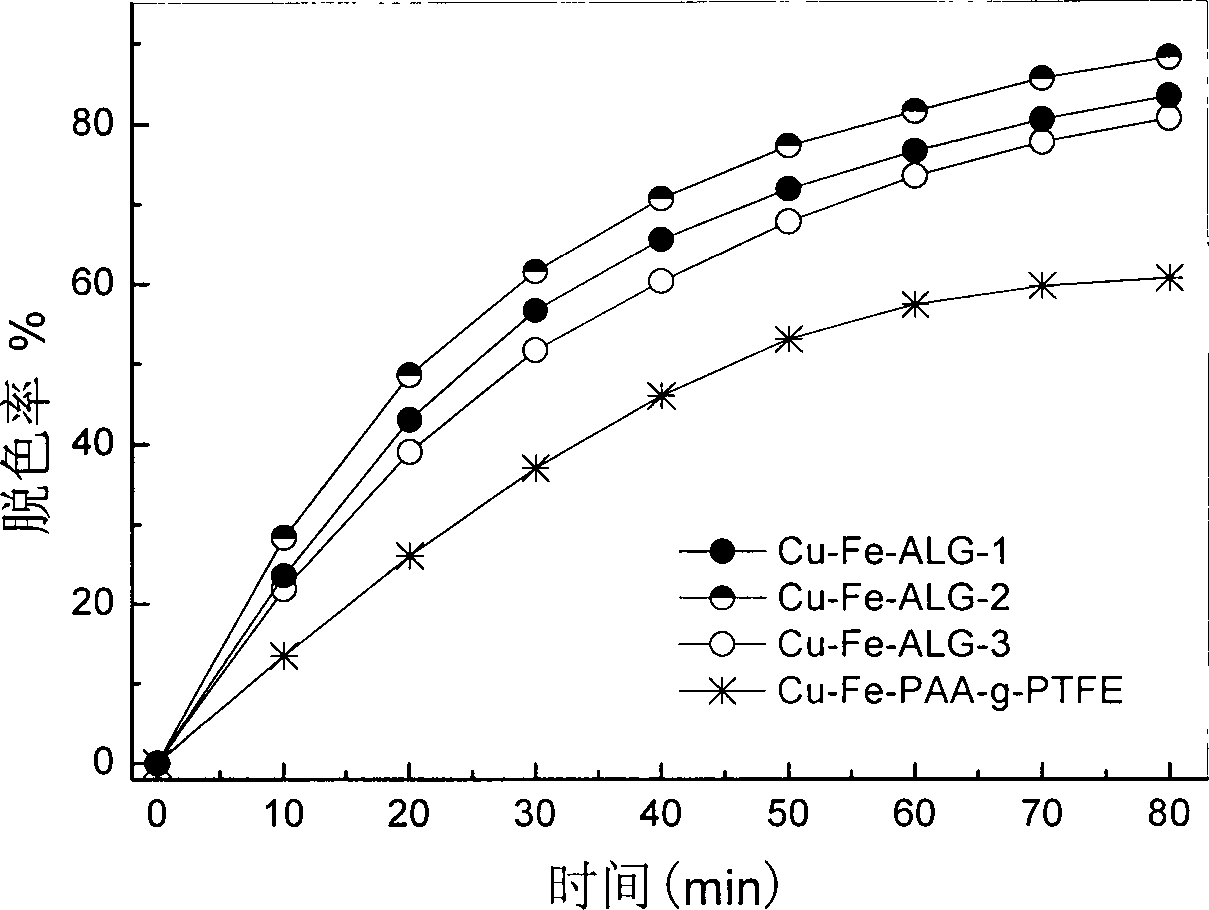

[0042] 4. The process is the same as step 4 in Example 1 respectively. The obtained yellow-green seaweed fiber metal complex catalyst is abbreviated as Cu-Fe-ALG-2. After measurement and calculation: the content of iron ion and copper ion in the catalyst Cu-Fe-ALG-2 is 61.26 mg / g and 73.82 mg / g respectively, and the dry fracture strength of the obtained catalyst is measured, and the obtained value is 220.54 cN.

Embodiment 3

[0044] 1. The process is the same as Step 1 in Example 1 respectively.

[0045] 2. The molar concentration ratio of iron ion and copper ion in the mixed aqueous solution of metal ions is adjusted to 1: 3, that is, the volume concentration of ferric chloride aqueous solution and copper sulfate aqueous solution is 0.025mol / L and 0.075mol / L respectively. All the other are with 2 in embodiment 1.

[0046] 3. The process is the same as step 3 in Example 1 respectively.

[0047] 4. The process is the same as step 4 in Example 1 respectively. The obtained yellow-green seaweed fiber metal complex catalyst is abbreviated as Cu-Fe-ALG-3. After measurement and calculation: the contents of iron ions and copper ions in the catalyst Cu-Fe-ALG-3 were 33.52 mg / g and 105.65 mg / g respectively, and the dry fracture strength of the obtained catalyst was measured, and the obtained value was 221.49 cN.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry breaking strength | aaaaa | aaaaa |

| Volume concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com