Cereal bionic rubbing threshing test bed

A test bench and grain technology, applied in the field of agricultural machinery, can solve the problems of inability to move and speed, accurate testing of mechanical properties of kneading and threshing, imperfect testing methods of bionic kneading and threshing microscopic process, and complicated design of motion mechanism, etc. Analyze, reduce disassembly time, and facilitate the effect of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

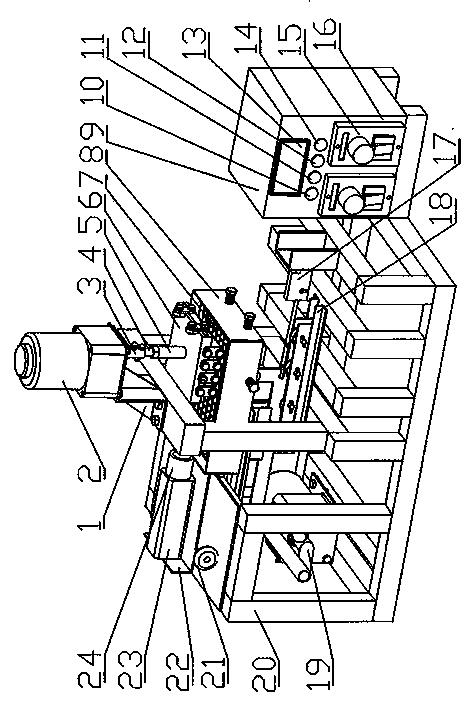

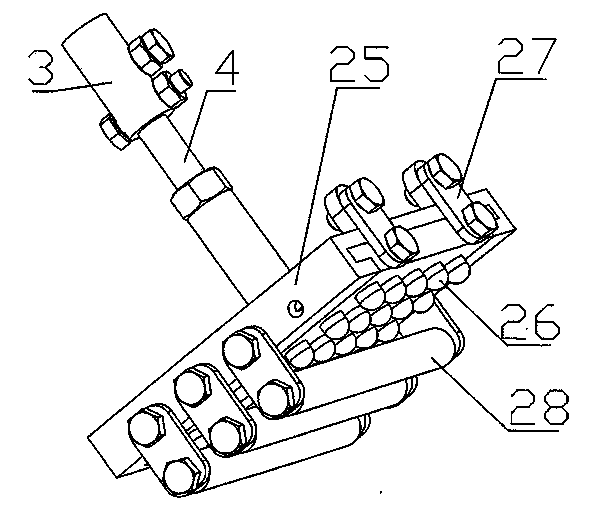

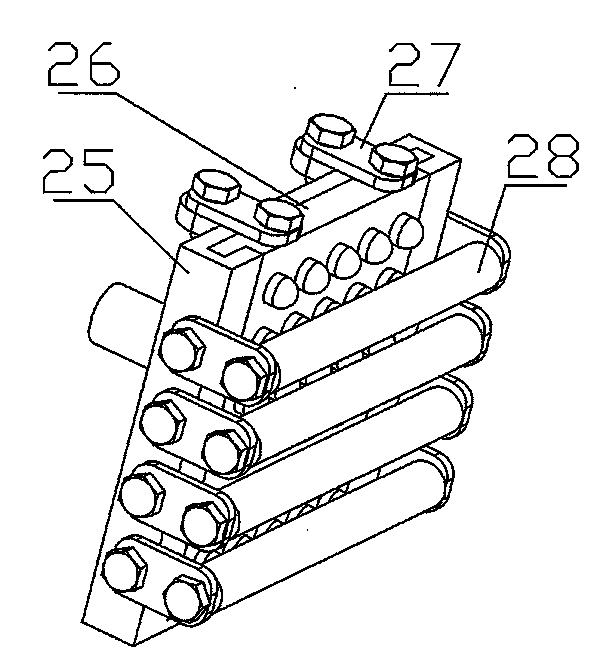

[0028] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6As shown, the present embodiment includes an upper take-off device 5, a lower take-off device 8, a tracking observation device 24, an instrument device 9 and a frame 20, and the upper take-off device 5 includes an upper take-off motor 2, an upper take-off support 1, a coupling sleeve 3. Adjust the stud 4 and the lifting platform 6, the lifting motor 2 is fixed on the frame 20 through the lifting bracket 1, the upper end of the coupling sleeve 3 is fixed on the output shaft of the lifting motor 2 by bolts, and the adjusting stud 4 The upper part is fixed on the lower end of the coupling sleeve 3 by bolts, and the rotation of the upper and lower motor 2 realizes the rotation of the adjustment stud 4. When the adjustment stud 4 rotates, it drives the upper and lower platform 6 fixed on its lower end to rotate. The screw connection of the upper take-off platform 6 realizes the vertical lifting of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com