Full-automatic continuous type secondary heating device for semisolid metal blanks

A semi-solid metal, secondary heating technology, applied in coil devices, induction heating, etc., can solve the unfavorable promotion and large-scale application of semi-solid processing technology, the inability to realize the complete automation of the heating process, and the difficulty in achieving consistent temperature distribution. Achieve the effect of meeting the requirements of mass production, avoiding uneven temperature in the axial direction, and avoiding coarse grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] specific implementation

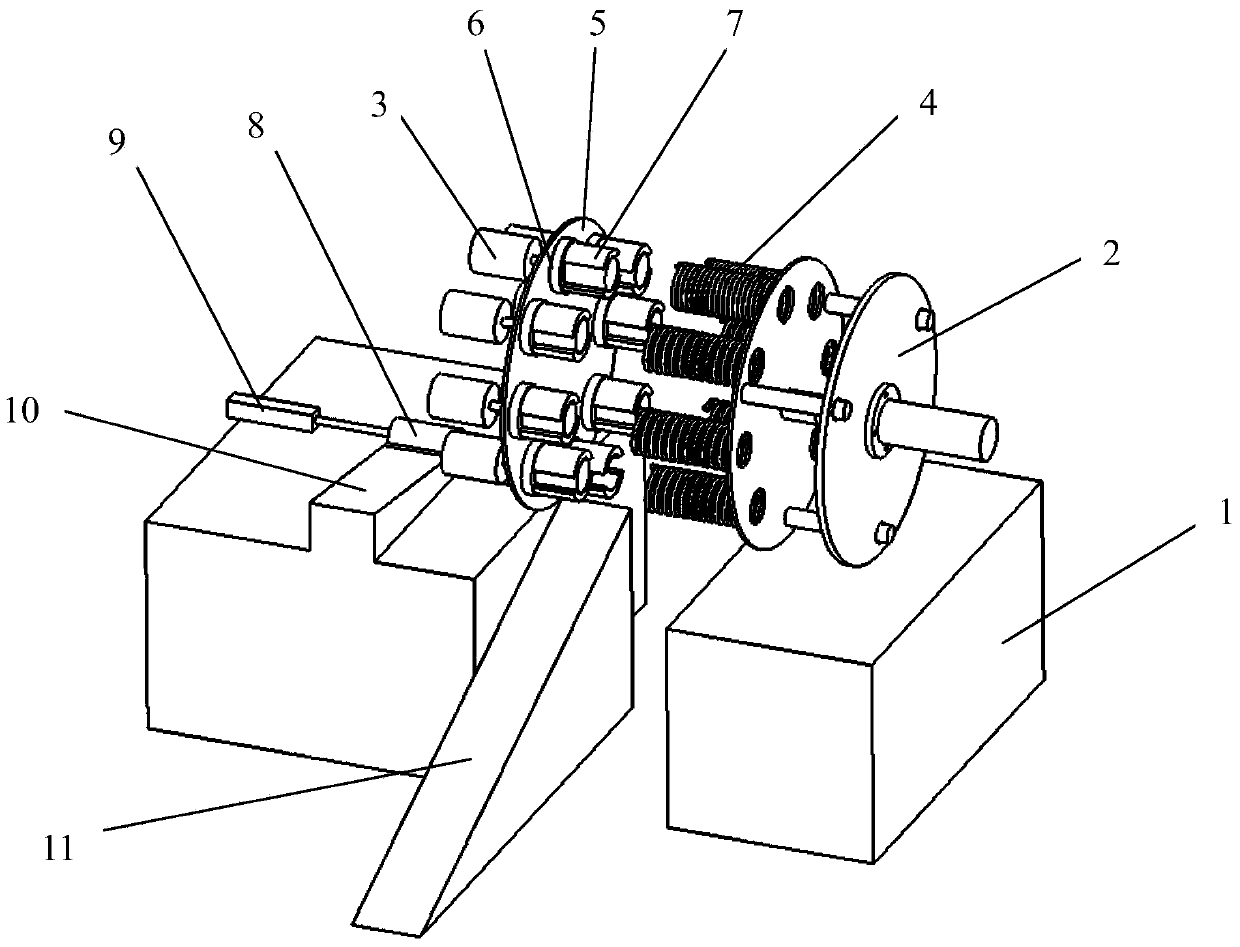

[0032] like figure 1 Shown is a fully automatic continuous secondary heating device for semi-solid processing of alloy blanks. etc. composition. The induction heating mechanism includes 7 induction heating coils 4 and a driving device 2. The induction heating coils 4 are installed on the driving device 2. The 7 induction heating coils 4 and a vacancy are evenly distributed along the circumferential direction at 45°, and the coils are connected in series with each other. The induction heating power supply is connected, and the induction heating coil 4 can reciprocate forward and backward through the driving device 2. The blank is placed on the supporting material carrying mechanism through the automatic feeding mechanism. There are 7 heating stations and 7 induction heating coils on the supporting material carrying mechanism. Corresponding positions, the blank completes the heating process of 7 stations, and the blank rotation mechanism is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com