Lithium ion battery positive pole piece as well as preparation method and lithium ion battery comprising pole piece

A technology for lithium-ion batteries and positive pole pieces, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as low capacity retention, poor structural stability, poor conductivity, etc., to reduce erosion, reduce battery impedance, Improve the effect of electrical contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

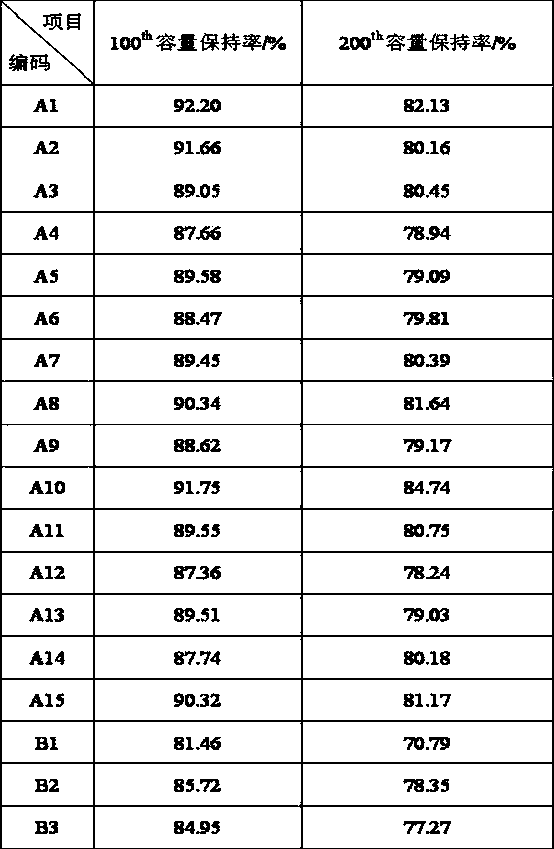

Examples

preparation example Construction

[0027] The present invention also provides a method for preparing the positive pole piece of the present invention, the method comprising the following steps:

[0028] S1, preparing a conductive film layer: preparing a first mixed solution containing a conductive active material, a second binder and a polar solvent and coating it on both sides of the positive current collector, and then vacuum drying to obtain a conductive film coated The positive current collector of the layer;

[0029] S2, preparing the active film layer: preparing a second mixture containing an organic solvent, a first binder, a positive electrode conductive agent, a rare earth oxide and a positive electrode active material and coating it on the positive electrode current collector coated with a conductive film layer On the surface, the positive electrode sheet can be obtained by drying.

[0030] According to the preparation method provided by the present invention, preferably, the mass ratio of the conduc...

Embodiment 1

[0050] The preparation method of the positive pole piece is as follows:

[0051] 1. Add 20 parts of binder PVDF into 80 parts of polar solvent NMP, stir until the viscosity change is less than 3%, and obtain a transparent colloidal binder; then weigh 15 parts of nano-graphite and add it to the above transparent colloid, and add 120 Parts of organic solvent NMP were stirred until the change in viscosity was less than 5%, to obtain a conductive film layer solution, which was left to stand for use.

[0052] 2. Weigh 8 parts of PVDF and add it to 100 parts of NMP, stir until the viscosity change is less than 3%, to obtain a transparent colloidal adhesive; then add 8 parts of conductive agent carbon black, stir until the viscosity change is less than 3%, to obtain an active film layer Conductive colloid; then 2 parts of CeO with a particle size of about 50 nanometers 2 Rare earth oxide additive and 100 parts Li 1.15 Ni 0.2 co 0.1 mn 0.55 o 2 The lithium-rich manganese-based s...

Embodiment 2

[0055] The preparation method of the positive pole piece of the present embodiment is as follows:

[0056] 1. Add 15 parts of binder PVDF to 60 parts of polar solvent NMP, stir until the viscosity change is less than 3%, and obtain a transparent colloidal binder; then weigh 10 parts of nano-graphite and 10 parts of graphene and add them to the above transparent colloid , while adding 140 parts of organic solvent NMP and stirring until the viscosity change is less than 5%, to obtain a conductive film layer solution, which is left to stand for use.

[0057] 2. Weigh 6 parts of PVDF and add it to 100 parts of NMP, stir until the viscosity change is less than 3%, to obtain a transparent colloidal adhesive; then add 6 parts of conductive agent carbon black, stir until the viscosity change is less than 3%, to obtain an active film layer Conductive colloid; then 2 parts of Y with a particle size of about 30 nanometers 2 o 3 Rare earth oxide additive and 100 parts Li 1.15 Ni 0.2 c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com