Anti-counterfeiting fiber and manufacturing method thereof as well as safety paper using anti-counterfeiting fiber and safety article

A technology of anti-counterfeiting fiber and manufacturing method, which is applied in papermaking, non-fiber pulp addition, and other household appliances, etc., can solve the problems of affecting anti-counterfeiting performance, degree of difficulty and fineness of fiber color segments, inconsistent fibers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

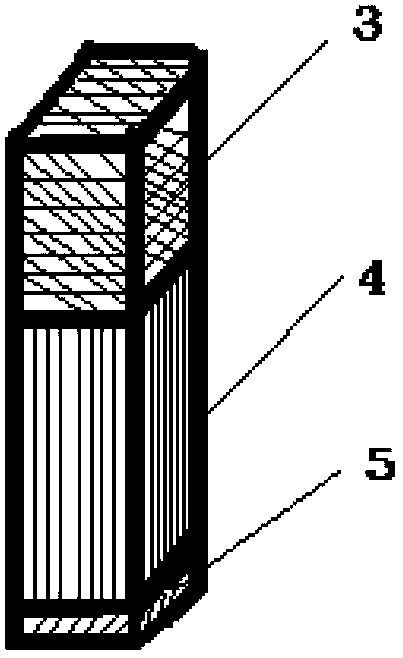

[0041] A kind of anti-counterfeiting fiber (such as figure 2 As shown), the anti-counterfeiting fiber is fixedly connected aluminum thin 3, chromium-zirconium copper foil 4 and titanium nitride thin 5 in the length direction. It is 2um.

[0042] A kind of anti-counterfeit fiber manufacturing method, concrete steps are as follows:

[0043] Step 1: Make a sheet with a multi-layer structure in the thickness direction: first process the aluminum thin and chromium-zirconium copper foil respectively, and then fix the aluminum thin and chromium-zirconium copper foil by ultrasonic welding, and then use ion plating The method is to plate titanium nitride on the outer surface of the chromium-zirconium copper foil;

[0044] Step 2: The sheet is cut into anti-counterfeiting fibers with three metal layers in the length direction by cutting method, the length of the anti-counterfeiting fibers is 3mm, and the thickness of the titanium nitride layer is 2um.

Embodiment 2

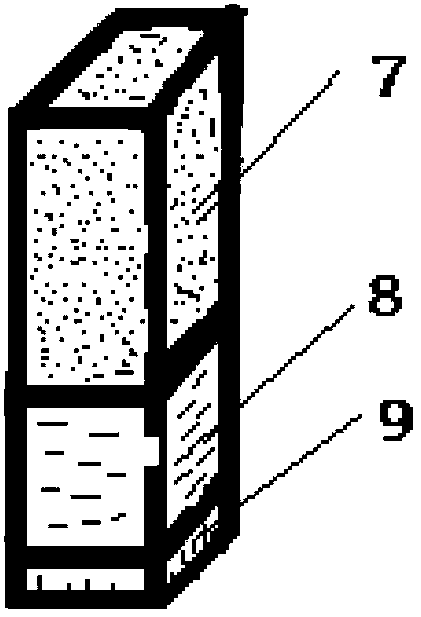

[0046] A kind of anti-counterfeiting fiber (such as image 3 shown), followed by the red PA layer 7 containing colorless fluorescent red material, the blue PA layer 8 of colorless fluorescent blue material and the yellow PA layer 9 of colorless fluorescent yellow material, which are fixedly connected in turn. The anti-counterfeiting fiber The length is 4mm, and the thickness of the yellow PA layer is 2um. The colors of the colorless fluorescent materials in the above three layers are red, blue and yellow respectively when excited by the excitation light.

[0047] A kind of anti-counterfeit fiber manufacturing method, concrete steps are as follows:

[0048] Step 1: Make a sheet with a multi-layer structure in the thickness direction: First, add colorless fluorescent red material, colorless fluorescent blue material and colorless fluorescent yellow material to three parts of molten PA liquid respectively, and wait for each colorless fluorescent The fluorescent material is distr...

Embodiment 3

[0051] A kind of anti-counterfeiting fiber (such as Figure 4 shown), followed by the red PA layer 7 containing colorless fluorescent red material, the blue PE layer 11 of colorless fluorescent blue material, the yellow PA layer 9 of colorless fluorescent yellow material, and the PA layer without any additives. The EVOH layer 10 and the red PE layer 12 containing a colorless fluorescent red material inside, the anti-counterfeiting fiber is 6mm in length, and the thickness of the yellow PA layer is 2um.

[0052] A kind of anti-counterfeit fiber manufacturing method, concrete steps are as follows:

[0053] Step 1: Make a sheet with a multi-layer structure in the thickness direction: first add the colorless fluorescent red material to two molten PA liquids, and add the colorless fluorescent blue material to one molten PE liquid, colorless The fluorescent yellow material is added to a molten PA liquid, and after various colorless fluorescent materials are distributed in the corre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com