Manufacturing method of anti-counterfeiting paper

A manufacturing method and technology of anti-counterfeiting paper, which is applied in papermaking, textiles and papermaking, fiber raw material processing, etc., can solve the problems of not being able to reflect the fineness of the original image and the fineness of the graphics, so as to achieve clear anti-counterfeiting graphics and reduce the possibility of falling off small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

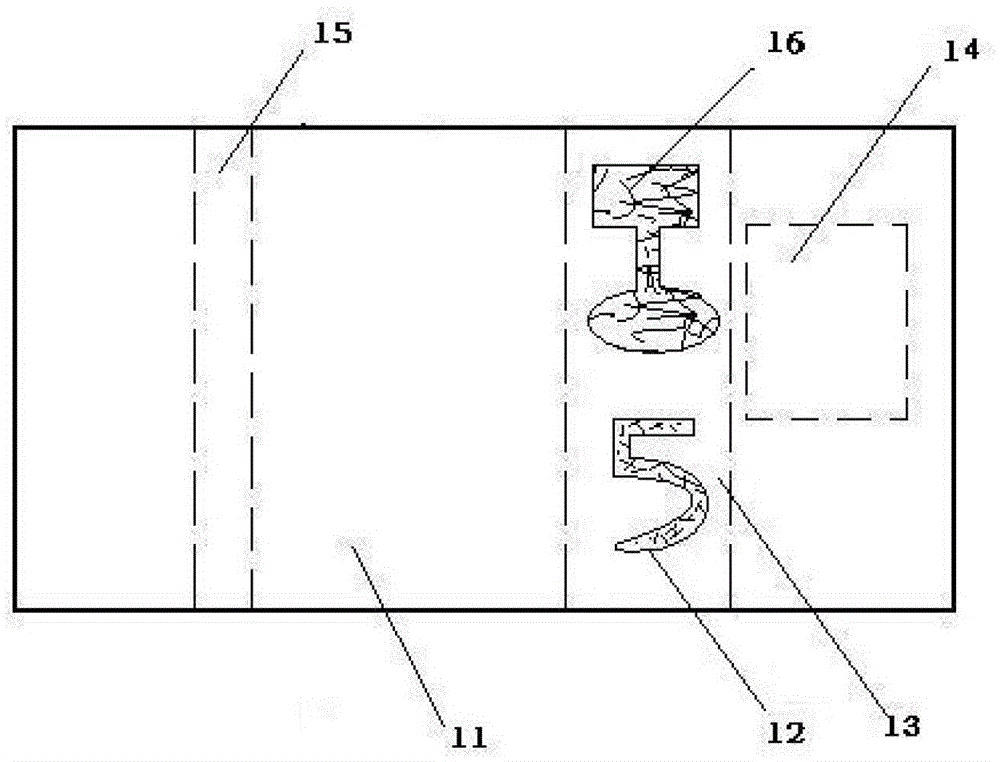

[0031] An anti-counterfeit paper, such as Figure 5 As shown, the surface of the anti-counterfeiting paper contains first, second, third, and fourth strip-shaped areas 13a, 13b, 13c, 13d, and the first, second, third, and fourth strip-shaped areas all contain discontinuous wet paper sheets 4 The discontinuous paper layer 12 of a specific shape is formed after drying. There is no overlap between the discontinuous paper layers of a specific shape. Each paper layer of a specific shape contains an anti-counterfeiting material 16, and the anti-counterfeiting paper in this embodiment The paper layer 12 with a discontinuous pattern contains the following raw materials by absolute dry weight: 4 parts of cotton fiber and 1 part of anti-counterfeiting material; the anti-counterfeiting material 16 used in this embodiment is colorless fluorescent fiber, and the papermaking fiber used is beaten Cotton fiber;

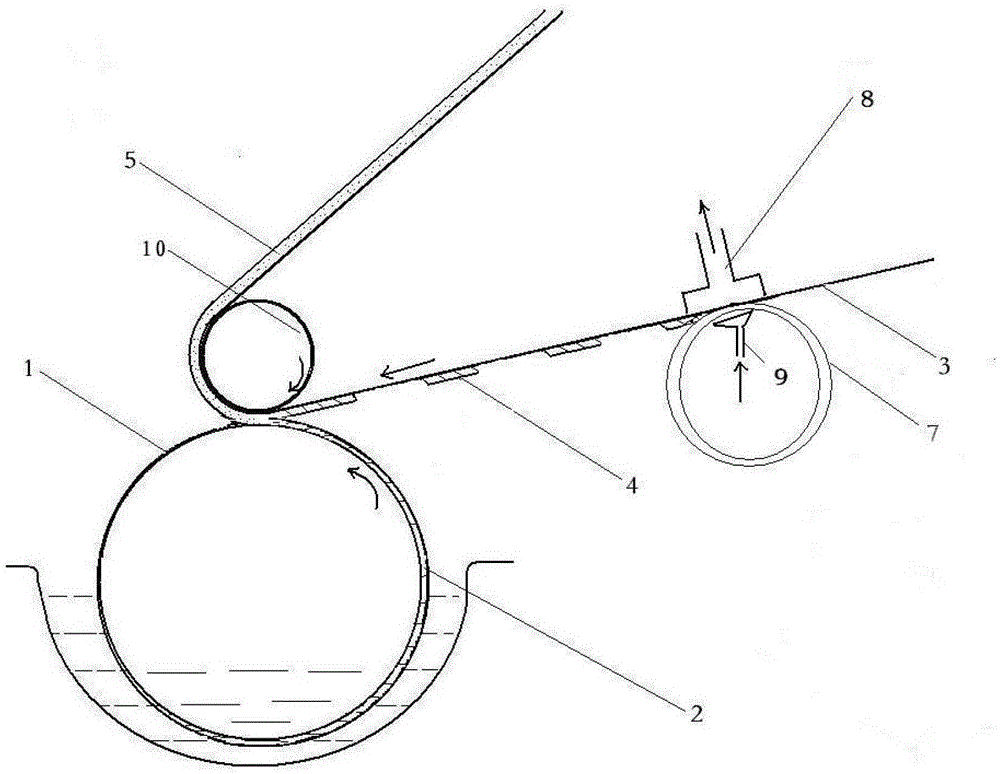

[0032] The manufacturing method of the aforementioned anti-counterfeiting paper is...

Embodiment 2

[0042] Step 1: Copy discontinuous wet paper 4:

[0043] (1) Add 1 part of anti-counterfeiting material and 4 parts of cotton fiber to water, stir and disperse, and mix into a suspension containing anti-counterfeit material;

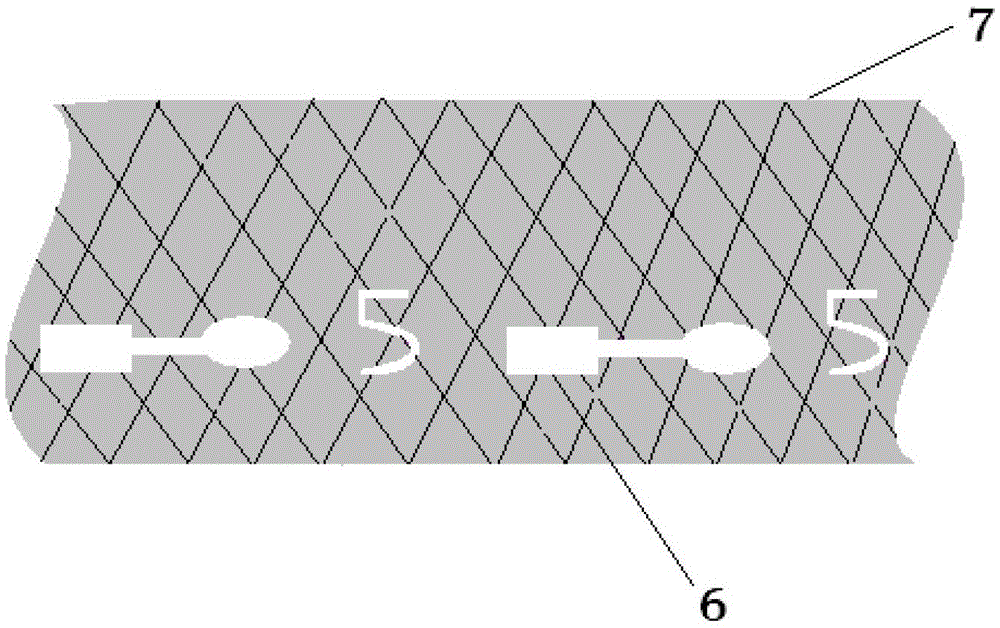

[0044] (2). Design and process the sheet-like article 7 containing the hollowed-out area 6, and fit the side of the sheet-like article 7 with the hollowed-out area 6 to the Fourdrinier;

[0045] (3) Install the duct 9 on the cylinder paper machine. The outlet of the duct 9 is close to the other side of the sheet 7 containing the hollow area 6 and at the corresponding position on the other side of the fourdrinier 3 of the cylinder paper machine. Install vacuum suction device 8;

[0046] (4) The suspension containing the anti-counterfeiting material 16 is continuously flowed through the conduit 9 to the other side of the moving sheet 7 containing the hollow area 6, and under the action of the vacuum suction 8, the suspension containing the anti-counterfeiting mater...

Embodiment 3

[0052] Step 1: Copy discontinuous wet paper 4:

[0053] (1). Add 1 part of anti-counterfeiting material and 10 parts of flax fiber into water, stir and disperse, and mix into a suspension containing anti-counterfeit material;

[0054] (2). Design and process the sheet-like article 7 containing the hollowed-out area 6. The side of the sheet-like article 7 with the hollowed-out area 6 is attached to the Fourdrinier. The shape of the hollowed-out area 6 on the side surface is irregular Geometric figures and regular geometric figures, there is no overlap between irregular geometric figures and regular geometric figures;

[0055] (3) According to the width and spacing of the hollow area 6, five ducts 9 with appropriate outlet widths are used. The duct outlets are rectangular, and the length direction is the same as the movement direction of the cylinder paper machine, and the width is 8mm. The ducts 9 are arranged at the appropriate spacing. And the position is installed on the cylinder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com