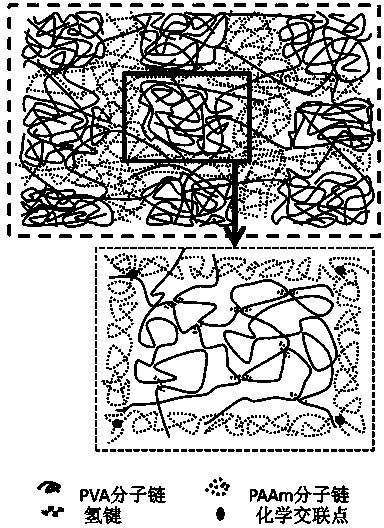

Preparation method of high-strength double-layer network hydrogel capable of being subjected to fatigue repair

A double-layer network, high-strength technology, applied in the field of polymer materials, can solve the problems of Young's modulus reduction, loss of high-strength hydrogel, and chemical cross-linking structure cannot be restored, and achieves simple preparation methods and a wide range of choices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a fatigue-repairable high-strength double-layer network hydrogel, the preparation steps of which are as follows:

[0030] Step (1): Weigh 64g of DMSO and 21g of deionized water into a conical flask, and mix well.

[0031] Step (2): Weigh 7.6g of PVA particles into a three-necked bottle, add 55g of the mixed solvent of DMSO and water prepared in advance, and place the remaining 30g of mixed solvent of DMSO and water at 3°C to 5°C for later use. Connect the water bath device and the stirring device, the temperature of the water bath is 95°C, and stir rapidly for 2.5 hours with nitrogen gas.

[0032] Step (3): Weigh 12.32g of acrylamide (AAm), 0.0025g of 2-ketoglutaric acid (KA), 0.0080g of N.N'-methylenebisacrylamide (MBAA) and dissolve in the remaining 30g of DMSO and In the mixed solvent of water, keep away from light.

[0033] Step (4): After the PVA particles are completely dissolved, remove the water bath, continue stirring for about 30 min...

Embodiment 2

[0039] A method for preparing a low-temperature self-repairing high-strength double-layer network hydrogel, the preparation steps of which are as follows:

[0040] Step (1): Weigh 64g of DMSO and 21g of deionized water into a conical flask, and mix well.

[0041] Step (2): Weigh 4.5g of PVA granules into a three-neck bottle, add 45g of a mixed solvent of DMSO and water prepared in advance, and store the remaining mixed solvent of DMSO and water at 3°C to 5°C for later use. A water bath device and a stirring device were connected to the three-necked bottle, the temperature of the water bath was 95° C., and the nitrogen gas was passed through and stirred rapidly for about 2 hours.

[0042] Step (3): Weigh 12.32g of AAm, 0.0025g of KA, and 0.0080g of MBAA and dissolve them in the remaining mixed solvent of 40g of DMSO and water, and store in the dark.

[0043] Step (4): After the PVA particles are completely dissolved, remove the water bath, continue stirring with nitrogen gas t...

Embodiment 3

[0048] A method for preparing a low-temperature self-repairing high-strength double-layer network hydrogel, the preparation steps of which are as follows:

[0049] Step (1): Weigh 64g of DMSO and 21g of deionized water into a conical flask, and mix well.

[0050] Step (2): Weigh 7.6g of PVA granules into a three-necked bottle, add 55g of mixed solvent of DMSO and water, and place the remaining mixed solvent at 3-5°C for later use. Connect the water bath device and the stirring device, the temperature of the water bath is 95°C, and stir rapidly for about 2.5 hours with nitrogen gas.

[0051] Step (3): Weigh 12.32g of AAm, 0.0025g of KA, and 0.0080g of MBAA and dissolve them in the remaining 30g of DMSO aqueous solution.

[0052] Step (4): After the PVA particles are completely dissolved, remove the water bath, continue stirring for about 30 minutes with nitrogen gas to cool the solution to about 50°C, add the mixed solution of AAm, KA, and MBAA, and stir rapidly for 5 minutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com