A kind of template-free two-step hydrothermal synthesis method of ultrafine type A zeolite

A technology of hydrothermal synthesis and no template agent, applied in the direction of A-type crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of high price and complicated steps, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

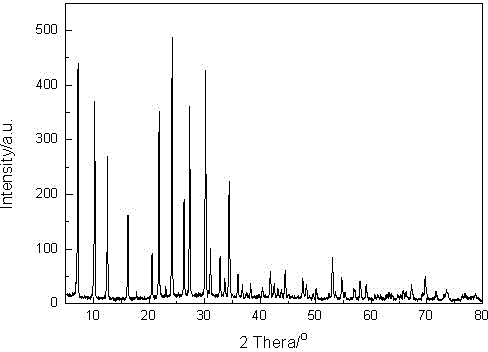

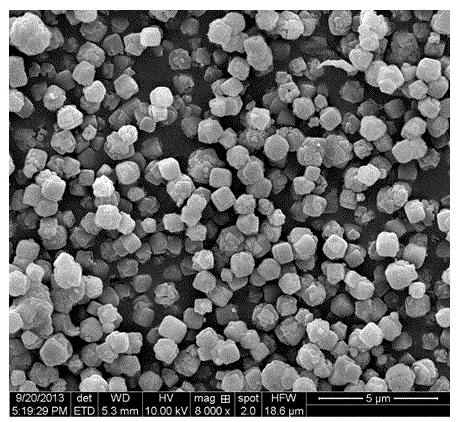

Image

Examples

Embodiment approach 1

[0021] Embodiment 1: The method for the template-free two-step hydrothermal synthesis of ultrafine type A zeolite in this embodiment is:

[0022] (1) According to the molar ratio of 2Na 2 O: 1.5Al 2 O 3 :1SiO 2 :150H 2 O Preparation of aluminum hydroxide, sodium metaaluminate, sodium silicate and distilled water;

[0023] (2) Dissolve the prepared sodium hydroxide into a sodium hydroxide solution with a concentration of 0.5 mol / L, divide it into two equally, put sodium metaaluminate and sodium silicate into two sodium hydroxide solutions, and then record them separately Is solution I and solution II;

[0024] (3) Pour solution I quickly into solution II to get the initial gel, and then put the initial gel at 35 o Under the condition of C, stir and age at a rate of 350r / min for 20h to obtain a mixed solution;

[0025] (4) The mixed solution obtained after the treatment in step (3) was crystallized for 8 hours under the hydrothermal reaction conditions of 80°C in a hydrothermal reactor,...

Embodiment approach 2

[0026] Embodiment 2: The method for the template-free two-step hydrothermal synthesis of ultrafine type A zeolite in this embodiment is:

[0027] (1) According to the molar ratio of 4Na 2 O: 0.5Al 2 O 3 :2.5SiO 2 :100H 2 O Preparation of aluminum hydroxide, sodium metaaluminate, sodium silicate and distilled water;

[0028] (2) Dissolve the prepared sodium hydroxide into a sodium hydroxide solution with a concentration of 2mol / L, divide it into two equally, and divide the sodium metaaluminate and sodium silicate into two sodium hydroxide solutions, and then record them as Solution I and Solution II;

[0029] (3) Pour solution I quickly into solution II to get the initial gel, and then put the initial gel at 45 o Under the condition of C, stir and age for 140h at a rate of 180r / min to obtain a mixed solution;

[0030] (4) The mixed solution obtained after the treatment in step (3) was crystallized for 3 hours under the hydrothermal reaction conditions of 120°C in a hydrothermal reactor...

Embodiment approach 3

[0031] Embodiment 3: The method for the template-free two-step hydrothermal synthesis of ultrafine type A zeolite in this embodiment is:

[0032] (1) According to the molar ratio of 4Na 2 O: 1Al 2 O 3 :2SiO 2 :120H 2 O Preparation of aluminum hydroxide, sodium metaaluminate, sodium silicate and distilled water;

[0033] (2) Dissolve the prepared sodium hydroxide into a sodium hydroxide solution with a concentration of 1mol / L, divide it into two equally, and divide the sodium metaaluminate and sodium silicate into two sodium hydroxide solutions, and then record them as Solution I and Solution II;

[0034] (3) Pour solution I quickly into solution II to get the initial gel, and then put the initial gel at 40 o Under the condition of C, stir and age at a rate of 300r / min for 110h to obtain a mixed solution;

[0035] (4) The mixed solution obtained after the treatment in step (3) is crystallized for 6 hours under hydrothermal reaction conditions at 100°C in a hydrothermal reactor, ultraso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com