Thickening agent, jam containing thickening agent and preparation methods of thickening agent and jam

A thickener and jam technology, which is applied in food ingredients as thickeners, food preparation, food science, etc., can solve the problems of reducing jam layering or water separation, uneven filling of jam, affecting the taste of jam, etc., to achieve Strong marketing value, good water retention performance, easy to produce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Part 1: Preparing the Thickener

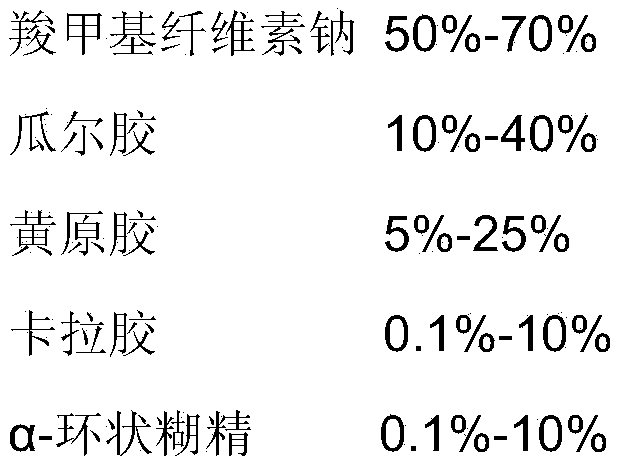

[0045] Prepare a thickener for jam, comprising the following components:

[0046]

[0047] After the above raw materials were sieved and mixed evenly, 1000 g of thickener was obtained.

[0048] Second part, utilize the thickener that makes in the present embodiment to produce pineapple fruit jam as the thickener of jam, and component is as follows:

[0049]

[0050] Concrete preparation steps are as follows:

[0051] Step 1, Prepare Thickener Solution

[0052] Mix the thickener and a certain proportion of white sugar evenly to obtain a mixture of thickener and edible sugar, add it to hot water above 90°C, stir until the thickener is completely dissolved, continue heating, and keep at 90°C for 10 minutes; , the mixing ratio of the thickener to white sugar is 1:5, and the ratio of the thickener to the edible sugar mixture to hot water is 1:5;

[0053] Step 2, prepare the pigment solution

[0054] Add β-carotene to warm water at...

Embodiment 2

[0063] Part 1: Preparing the Thickener

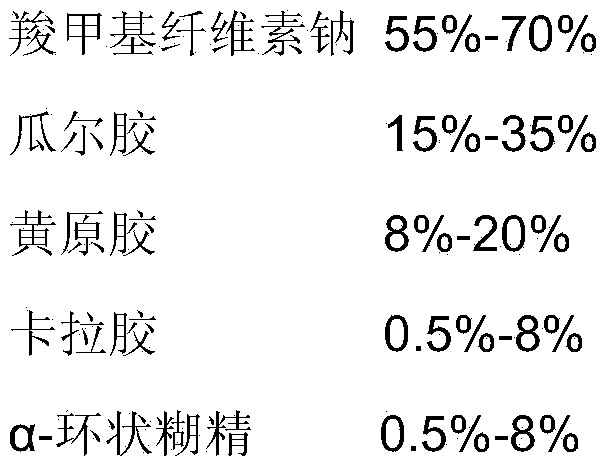

[0064] Prepare a thickener for jam, comprising the following components:

[0065]

[0066] After the above raw materials were sieved and mixed evenly, 1000 g of thickener was obtained.

[0067] Second part, utilize the thickener that embodiment 2 makes to produce strawberry fruit jam as the thickener of jam, and component is as follows:

[0068]

[0069]

[0070] Concrete preparation steps are as follows:

[0071] Step 1, thickener solution preparation

[0072] Mix the thickener and a certain proportion of white sugar evenly, add it to hot water above 90°C, stir until the thickener is completely dissolved, continue heating, and keep at 90°C for 10 minutes; wherein, the thickener and white sugar The mixing ratio is 1:5, and the ratio of the thickener to the edible sugar mixture to hot water is 1:5;

[0073] Step 2, prepare the pigment solution

[0074] Monascus red pigment was first added to warm water at 50°C at a ratio of...

Embodiment 3

[0083] Prepare a thickener for jam, comprising the following components:

[0084]

[0085]

[0086] After the above raw materials were sieved and mixed evenly, 1000 g of thickener was obtained.

[0087] Second part, utilize the thickener that embodiment 3 makes to produce peach fruit jam as the thickener of jam, and component is as follows:

[0088]

[0089] Concrete preparation steps are as follows:

[0090] Step 1, thickener solution preparation

[0091] Mix the thickener and a certain proportion of white sugar evenly, add it to hot water above 90°C, stir until the thickener is completely dissolved, continue heating, and keep at 90°C for 10 minutes; wherein, the thickener and white sugar The mixing ratio is 1:5, and the ratio of the thickener and white sugar mixture to hot water is 1:5;

[0092] Step 2, prepare the pigment solution

[0093] Add β-carotene to warm water at 45°C at a ratio of 1:10, stir until completely dissolved, and obtain a pigment solution for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com