positive displacement pump

A technology of positive displacement pump and pump assembly, applied in the direction of pump, rotary piston pump, pump element, etc., can solve the problems of cracking of lubricating film, end-side wear, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

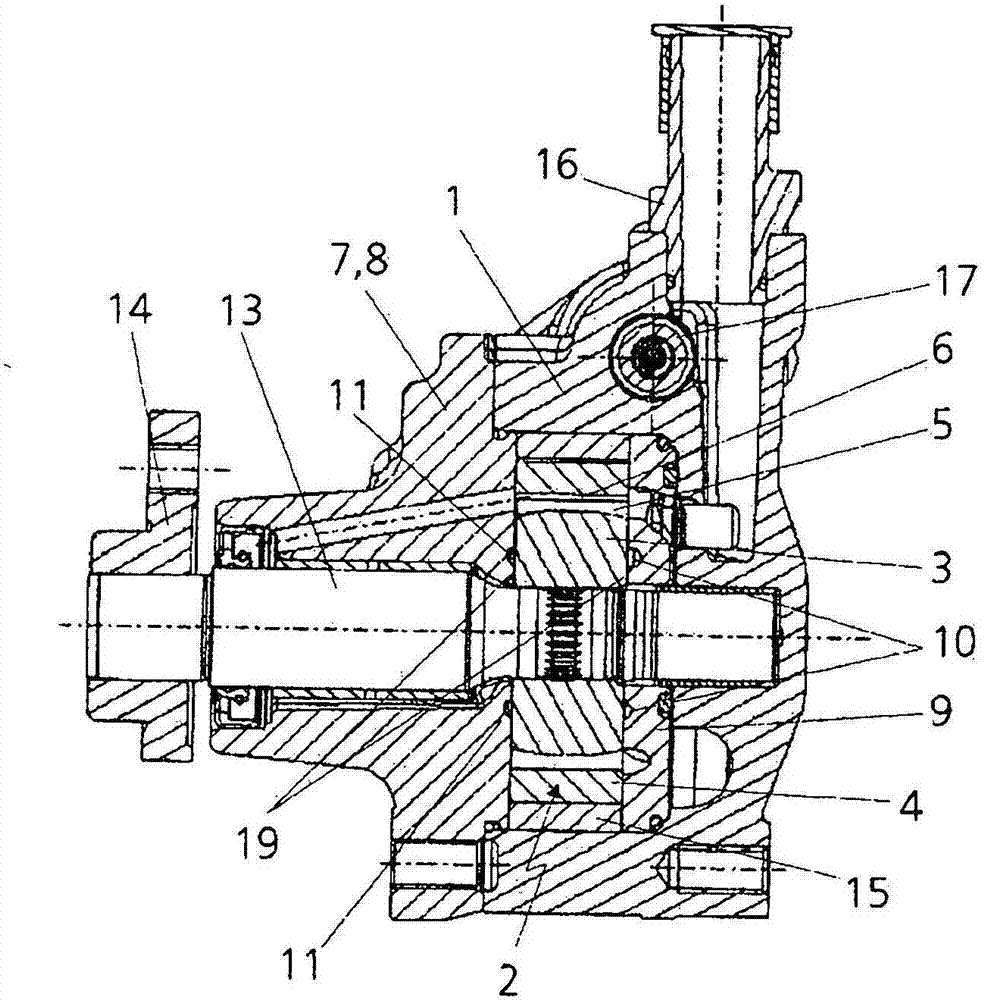

[0031] The invention will be described below on the basis of a vane pump. However, the solution according to the invention is of course also suitable for roller pumps.

[0032] Vane pumps are widely known, for which reference is made to the documents mentioned at the outset, so only the components that are relevant to the invention will be discussed in detail below.

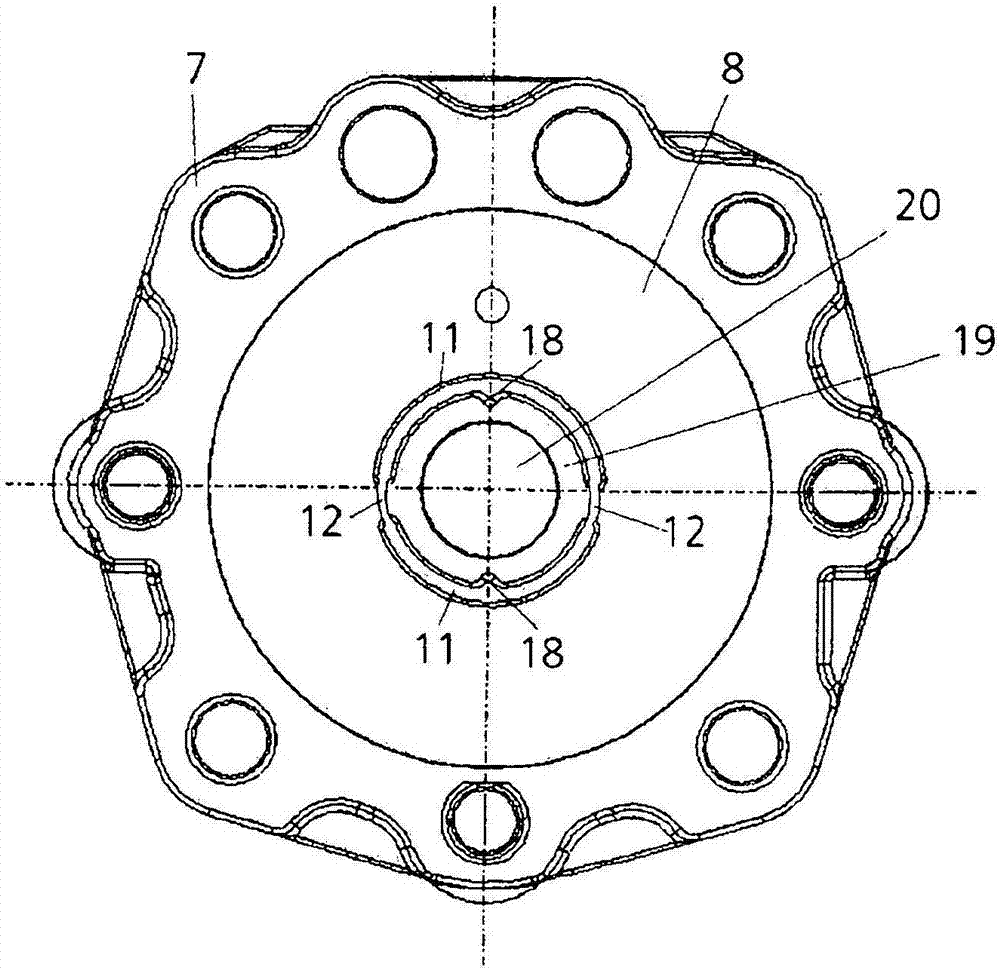

[0033] A pump assembly 2 is installed inside the housing 1 , which includes a rotor 3 , a cam ring 4 surrounding the rotor and a plurality of working slides 5 distributed on the circumference of the rotor 3 . A working chamber 6 separated by a working slide 5 is formed between the cam ring 4 and the rotor 3 . Control discs 8 and 9 are arranged on both end faces of the rotor. The control panel 8 is integrated into the housing cover 7 or the housing cover.

[0034] Two opposing kidney-shaped supply channels 10 are arranged in the control disk 9 . In the same way, the control disk 8 as housing cover 7 has two bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com