Quasi-three dimensional prefabricated member

A prefabricated, quasi-three-dimensional technology, applied in the direction of textiles, papermaking, non-woven fabrics, etc., to achieve the effect of improving carbon residue, good structure distribution performance, and reducing carbonization process links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

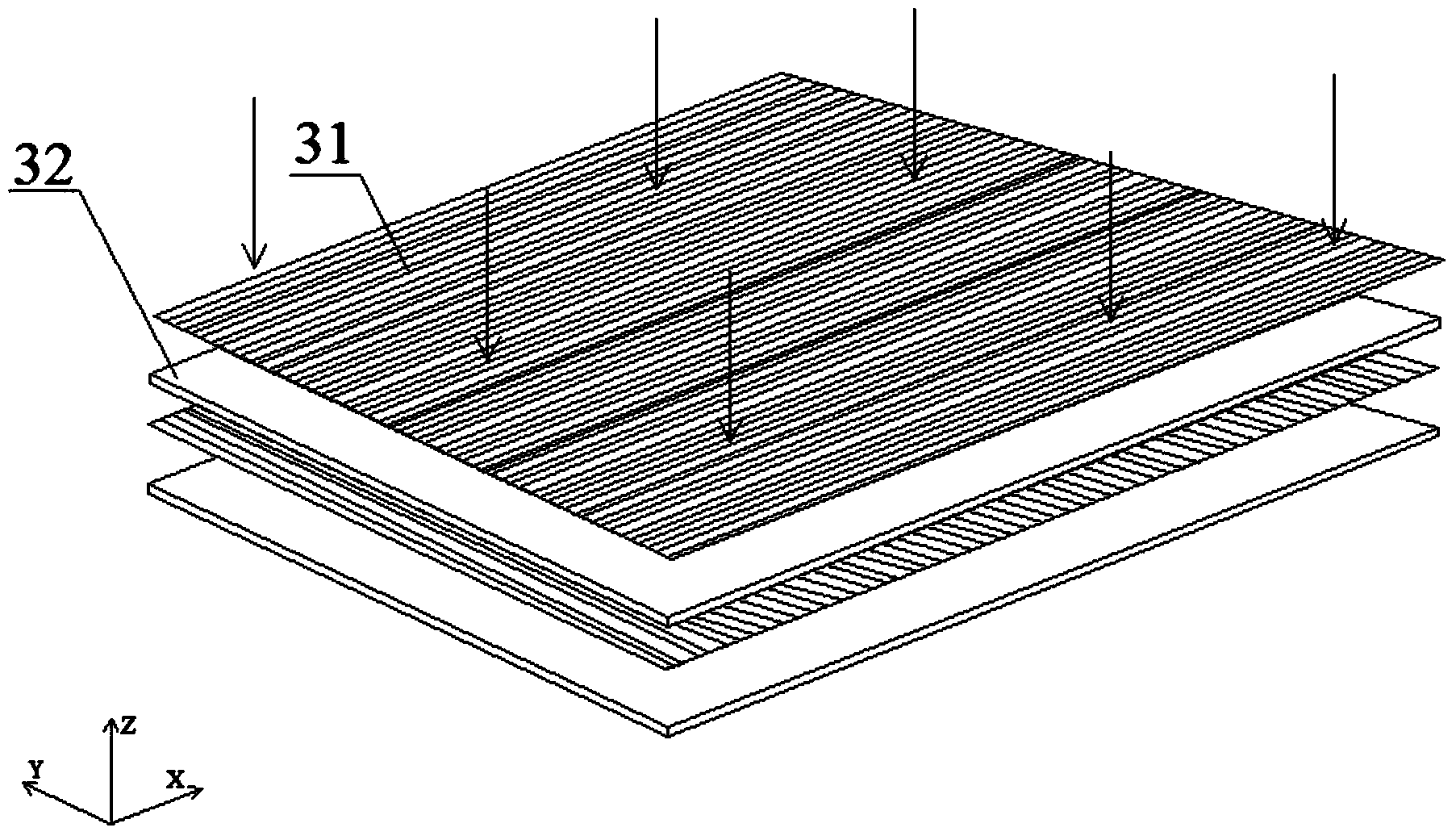

[0037] Cut polyacrylonitrile-based long carbon fibers into polyacrylonitrile-based chopped carbon fibers with a length of 60mm, spray water to keep the chopped carbon fibers at 40% humidity, and keep the temperature at 25°C for 5 hours to soften and modify them, and take out the chopped carbon fibers After the fibers are formed along the direction of the roller axis of the single-roller opening machine, an "S"-shaped needle arrangement is formed, and the flocculent fiber fleece is opened with a 90% looseness, and then combed by a carding machine into a thickness of 0.3mm and an area density of 200g / m 2 Thin mesh felt fabric (net tire). The polyacrylonitrile-based long carbon fiber is radially laminated and needle-punched to a thickness of 0.3mm and a surface density of 250g / m 2 thin layer laid fabric. Such as figure 1 As shown, the latitude-free fabrics and mesh tires are alternately laminated, and the adjacent latitude-free fabric layers are interlaced at an angle of 0° / 90°...

Embodiment 2

[0039] Cut polyacrylonitrile-based long carbon fibers into polyacrylonitrile-based chopped carbon fibers with a length of 70 mm, spray the surface with octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate, and place them in an airtight container for 20 hours. It is softened and modified, taken out, dehydrated and dried at room temperature, chopped fibers along the direction of the roller axis of the single-roller opener, forming an "S"-shaped needle arrangement, and loosened to 90% flocculent fiber fleece, and then It is combed by a carding machine to a thickness of 0.15mm and a surface density of 80g / m 2 Thin mesh felt fabric (net tire). The polyacrylonitrile-based long carbon fiber is oriented and laminated to a thickness of 0.15mm and an area density of 100g / m 2 thin layer laid fabric. Such as figure 1 As shown, the latitude-free fabrics and mesh tires are alternately laminated, and the adjacent latitude-free fabric layers are interlaced at an angle of 0° / 90°, and...

Embodiment 3

[0041] Cut polyacrylonitrile-based long carbon fibers into polyacrylonitrile-based chopped carbon fibers with a length of 80mm, spray water to keep the chopped carbon fibers at 70% humidity, and keep the temperature at 25°C for 3 hours to soften and modify them. After fiber cutting, along the direction of the roller axis of the single-roller opening machine, an "S"-shaped needle layout is formed, and the flocculent fiber fleece is opened to 90% looseness, and then combed by a carding machine into a thickness of 0.2mm and an area density of 125g / m 2 Thin mesh felt fabric (net tire). The polyacrylonitrile-based long carbon fiber is oriented and laminated to a thickness of 0.25mm and a surface density of 200g / m 2 thin layer laid fabric. Such as figure 1 As shown, the latitude-free fabrics and mesh tires are alternately laminated, and the adjacent latitude-free fabric layers are interlaced at an angle of 0° / 90°, and the outermost two layers are all latitude fabrics. According ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com