Equipment for producing fuel from domestic waste

A domestic garbage and fuel technology, applied in the field of environmental protection petrochemical equipment, can solve the problems of not reaching the minimum calorific value, low calorific value of gas products, and low utilization rate of resources, so as to reduce processing costs, improve economic benefits, and reduce volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

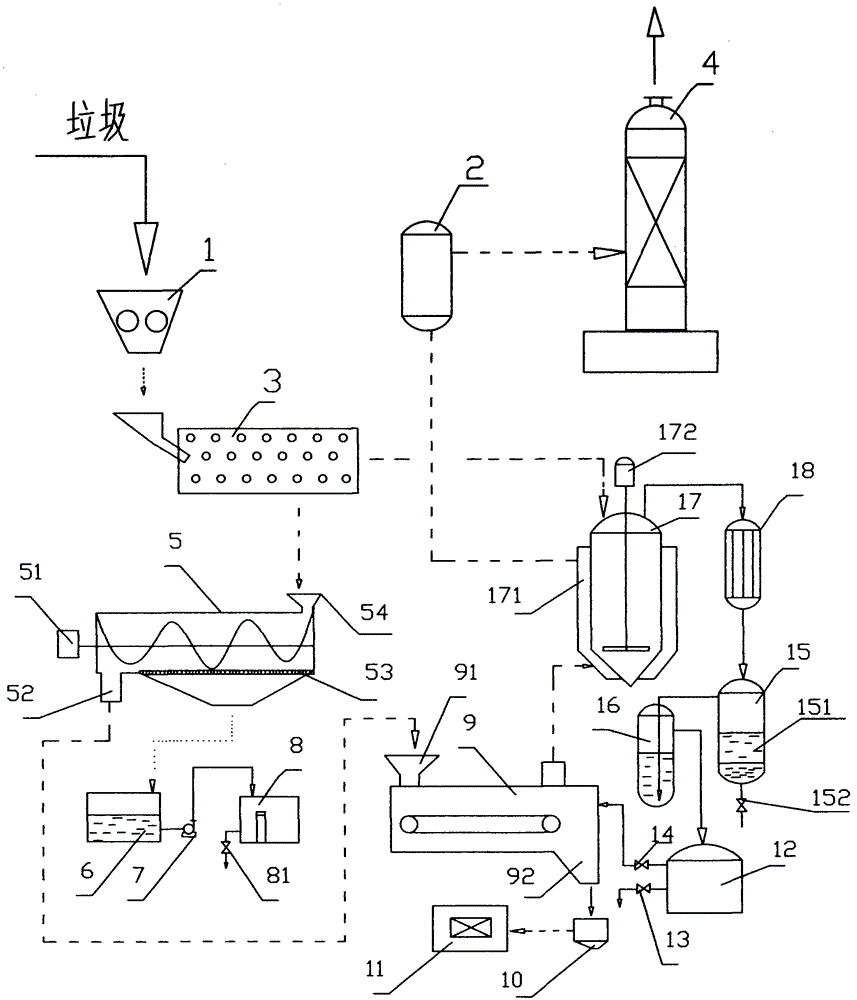

[0022] According to the present invention, a device for producing fuel from domestic waste is provided, including: a waste breaker (1), a flue gas waste heat boiler (2), a sorting machine (3), and flue gas purification treatment equipment (4) , dehydrator (5), sewage collection tank (6), sewage pump (7), sewage purification standard treatment equipment (8), incinerator (9), pyrolysis reactor (17), condenser (18), gas Composed of a liquid separator (15), a water seal tank (16) and a gas storage cabinet (12); it is characterized in that:

[0023]The discharge port of the garbage crusher (1) is connected to the feed port of the sorter (3), and the light material (that is, mainly waste plastics) sorted out by the sorter (3) is connected to the outlet of the sorter (3). The feed port of the pyrolysis reactor (17), the heavy material discharge port selected by the classifier (3) is connected to the feed port (54) of the dehydrator (5), and the dehydrator The fuel charging box (91) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com