Powdery soil curing agent for curing road base course and subbase course

A technology for soil curing agent and pavement base, applied in soil conditioning materials, chemical instruments and methods, organic fertilizers, etc., can solve problems such as large influence of environmental temperature and environmental pollution, and achieve improved impermeability, final strength, specific surface area, etc. added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

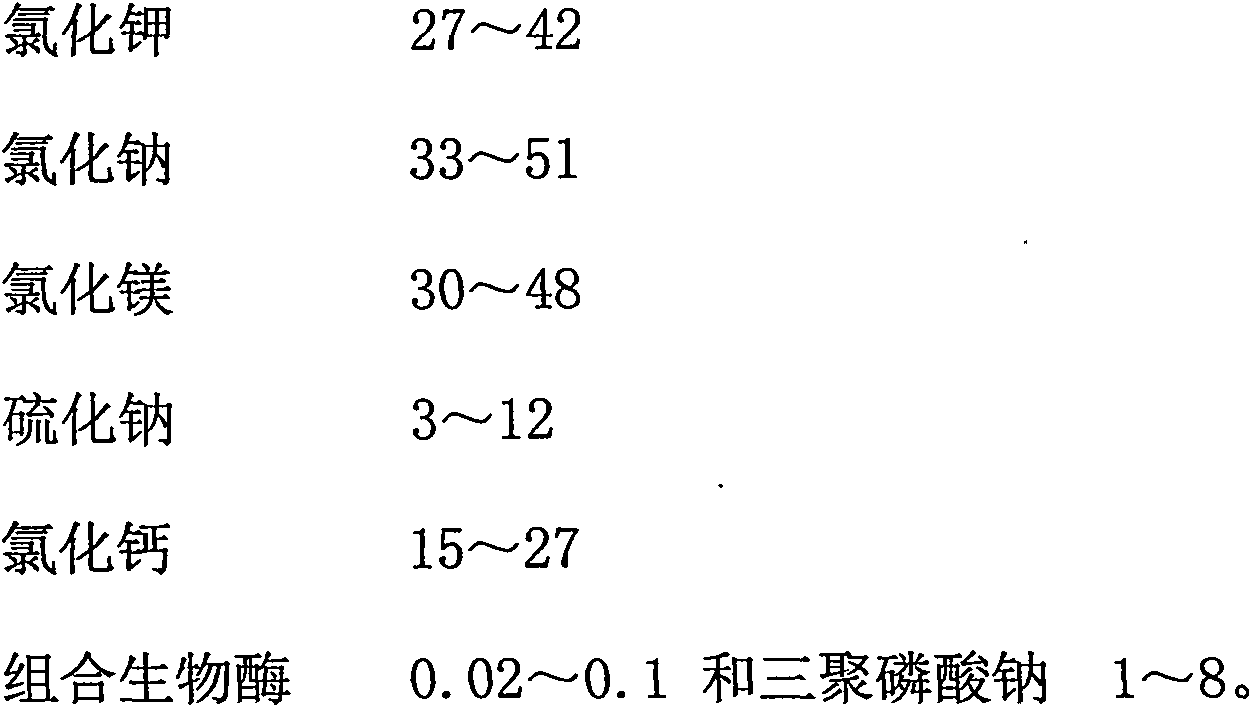

[0036] Example 1: Take 27Kg of potassium chloride, 51Kg of sodium chloride, 30Kg of magnesium chloride, 12Kg of sodium sulfide, 15Kg of calcium chloride, 0.02Kg of combined biological enzyme and 8Kg of sodium tripolyphosphate to obtain the present invention.

Embodiment 2

[0037] Example 2: Take 42Kg of potassium chloride, 33Kg of sodium chloride, 48Kg of magnesium chloride, 3Kg of sodium sulfide, 27Kg of calcium chloride, 0.1Kg of combined biological enzyme and 1Kg of sodium tripolyphosphate to obtain the present invention.

Embodiment 3

[0038] Example 3: Take 30Kg of potassium chloride, 47Kg of sodium chloride, 34Kg of magnesium chloride, 10Kg of sodium sulfide, 18Kg of calcium chloride, 0.08Kg of combined biological enzyme and 3Kg of sodium tripolyphosphate to obtain the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com