A kind of cationic nano particle surface modifier for cotton

A surface modifier and nanoparticle technology, applied in the field of textile printing and dyeing, can solve the problems of long modification time, affecting the moisture absorption and air permeability of cotton fabrics, and high energy consumption, and achieve the effect of simple preparation method and improved dyeing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

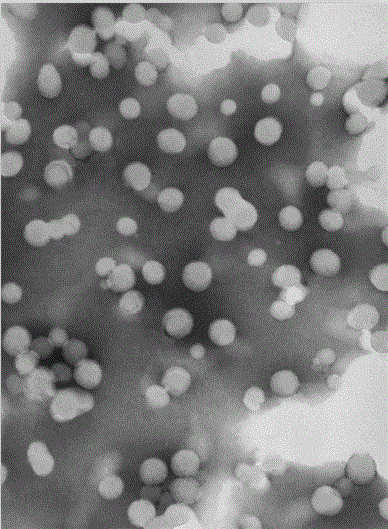

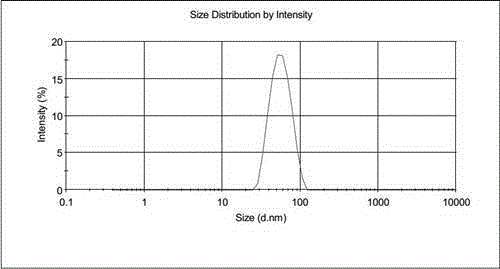

[0019] Nitrogen was passed into a four-necked flask with a stirring device, a condenser, and a nitrogen gas introduction device for 15 minutes, and a certain amount of deionized water and cetyltrimethylammonium chloride with a weight percentage of 1.2% were added to emulsify agent, stirred at a rotating speed of 300r / min for 5min to make the emulsifier evenly distributed in water; adding weight percentages were respectively 7.5% and 12.5%, 9.5% and 10.5%, 12% and 8%, 15% and 5%, 17.5% and 2.5%, 19.2% and 0.8% of styrene and butyl acrylate as comonomers, pre-emulsified for 30min; the reaction temperature was raised from room temperature to (80±1)°C, and 0.01% by weight of Azobisisobutylamidine hydrochloride (AIBA) initiator; heat preservation reaction at (80±1)°C for 3 hours, and naturally cool down to 40-50°C to make polymers with positively charged particles on the surface and a particle size of 20-200nm matter nanoparticles.

Embodiment 2

[0021] Nitrogen was passed into a four-necked flask equipped with a stirring device, a condenser, and a nitrogen gas introduction device for 15 minutes, and a certain amount of deionized water was added and the weight percentages were 0.2%, 0.4%, 0.6%, 0.8%, and 1.0% respectively. , 1.2% cetyl trimethyl ammonium chloride (bromide), ethylene bis (hexadecyl dimethyl chloride (bromide) ammonium), methacryloxyethyl hexadecyl di One of methyl ammonium chloride (bromide) and maleic acid diethylenyl bis(hexadecyl dimethyl bromide (chlor) ammonium) is an emulsifier, at a speed of 300r / min Stir for 5 minutes to make the emulsifier evenly distributed in water; add 19.2% and 0.8% by weight of styrene and butyl acrylate as comonomers, and pre-emulsify for 30 minutes; the reaction temperature rises from room temperature to (80±1)°C , add 0.01% by weight of azobisisobutylamidine hydrochloride (AIBA) initiator; keep the reaction at (80±1)°C for 3 hours, and naturally cool down to 40-50°C to ...

Embodiment 3

[0023] Nitrogen was passed into a four-necked flask with a stirring device, a condenser, and a nitrogen gas introduction device for 15 minutes, and a certain amount of deionized water and cetyltrimethylammonium chloride with a weight percentage of 1.2% were added to emulsify Stir for 5min at a rotating speed of 300r / min to make the emulsifier evenly distributed in water; add 19.2% and 0.8% styrene and butyl acrylate as comonomers, and pre-emulsify for 30min; When the temperature rises to (80±1)°C, add azobisisobutylamidine hydrochloride (AIBA ), azobisisobutylimidazoline hydrochloride (AIBA), azobiscyanovaleric acid (ACVA), azobisisopropylimidazoline (AIP) as the initiator; at (80± 1) Insulate and react at ℃ for 3 hours, then cool down naturally to 40-50 ℃ to make polymer nanoparticles with a positively charged surface and a particle size of 20-200nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com