A kind of manufacturing method of polytetrafluoroethylene small-caliber volumetric flask

A technology of polytetrafluoroethylene and its production method, which is applied to bottles, other household utensils, household utensils, etc., can solve problems such as unfavorable protection of the environment and health, increased losses, and product cracking, so as to reduce processing risks and save processing costs , Reduce the effect of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

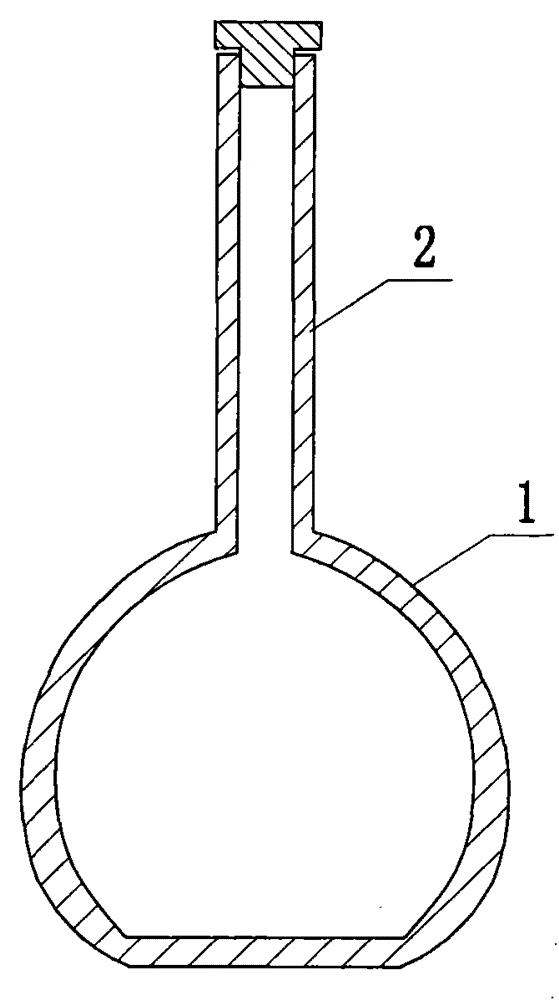

[0040] Such as figure 1 Shown, the structure of the volumetric flask to be processed in the present embodiment is as follows:

[0041] The volumetric flask includes a spherical bottle body 1, and the upper end of the spherical bottle body 1 is provided with a first cylindrical bottleneck of an integrally formed structure, that is, the volumetric flask is changed into a gourd-shaped structure.

[0042] Its processing technology is as follows:

[0043] Step 1. Mold

[0044] Prepare the outer mold of the volumetric flask corresponding to the shape and structure of the above-mentioned volumetric flask, the outer mold of the volumetric flask is a steel mold; the outer mold of the volumetric flask in this embodiment includes a spherical bottle body outer mold and a first cylindrical bottleneck outer mold.

[0045] Prepare the internal mold of the volumetric flask, the internal mold of the volumetric flask is a rubber bladder, the thickness of the rubber bladder is 2.5mm, and the r...

Embodiment 2

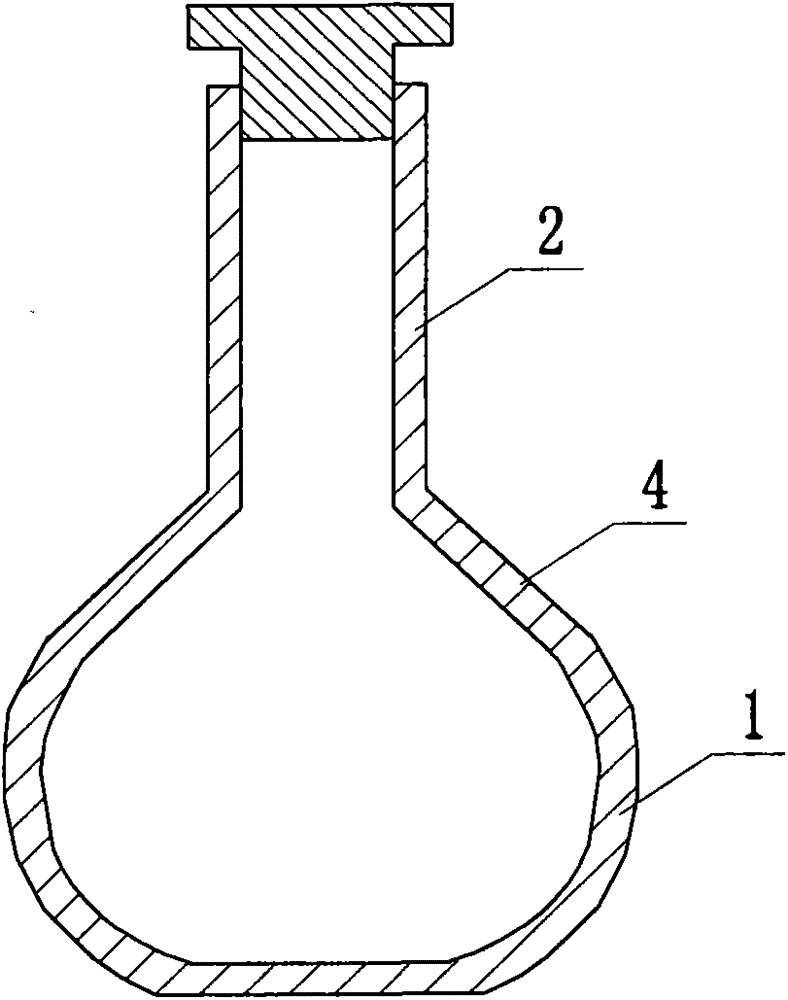

[0061] Such as image 3 As shown, the difference between the present embodiment and the first embodiment is that a frustoconical transitional bottleneck 4 is connected between the spherical bottle body 1 and the first cylindrical bottleneck 2 .

[0062] Its processing technology is as follows:

[0063] Step 1. Mold

[0064] Prepare the volumetric flask outer mold corresponding to the above-mentioned volumetric flask shape and structure, and the volumetric flask outer mold is a steel mold; the volumetric flask outer mold described in the present embodiment includes a spherical bottle body outer mold, a first cylindrical bottleneck outer mold and a circular bottle neck outer mold. The outer mold of the trapezoidal transition bottleneck has three parts.

[0065] Prepare the internal mold of the volumetric flask, the internal mold of the volumetric flask is a rubber bladder, the thickness of the rubber bladder is 2.5mm, and the rubber bladder is placed in the external mold of th...

Embodiment 3

[0079] Such as Figure 4 Shown, the structure of the volumetric flask to be processed in the present embodiment is as follows:

[0080] The volumetric flask includes a cylindrical bottle body 5, a transition horn neck 7 is connected to the upper end of the cylindrical bottle body, and a second cylindrical bottle neck 6 is connected to the upper end of the transition horn neck.

[0081] Its processing technology is as follows:

[0082] Step 1. Mold

[0083] Prepare the volumetric flask outer mold corresponding to the above-mentioned volumetric flask shape and structure, and the volumetric flask outer mold is a steel mold; the volumetric flask outer mold described in this embodiment includes a cylindrical bottle body outer mold, a transition horn neck outer mold and a second The outer mold of the cylindrical bottleneck has three parts.

[0084] Prepare the internal mold of the volumetric flask, the internal mold of the volumetric flask is a rubber bladder, the thickness of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com