Novel chuck

A chuck, a new type of technology, applied in the direction of clamping, clamping devices, supports, etc., can solve the problems of poor wear resistance, easy deformation, and high price of white steel, and achieve long mission life, moderate price, and good wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

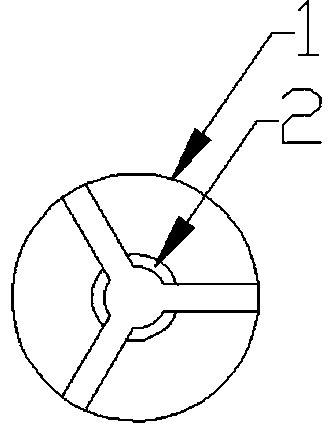

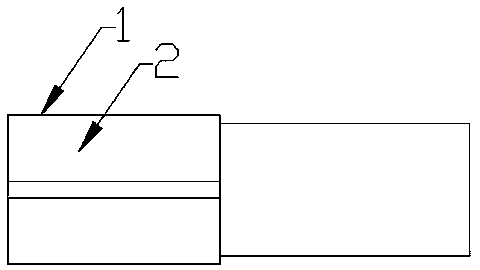

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] A new type of chuck, such as figure 1 , figure 2 As shown, it includes a collet body 1 and a collet clamping part 2; the collet clamping part 2 is welded to one end of the collet body 1 by a special process to form a new collet.

[0014] The specific operation is as follows: first put the drill bit or milling cutter into the clamping part 2 of the chuck, tighten it, then put the chuck body 1 with the drill bit or milling cutter into the installation hole of the equipment and fix it, and then the equipment can be used. Since the clamping part 2 of the chuck is made of tungsten steel, the wear resistance is higher, the service life is relatively longer, and the price is moderate.

[0015] In the present invention, as a variant embodiment, the clamping portion of the chuck can be freely designed. Therefore, the protection scope of the present invention is subje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com