Preparation method and use of degradable polymer nano-microcapsules

A technology for degrading polymers and nano-microcapsules. It is applied in the direction of microcapsules, nanocapsules, and medical preparations of non-active ingredients. It can solve the problems of adverse therapeutic effects and low drug loading, and achieve fast release speed and preparation The effect of simple process and uniform molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

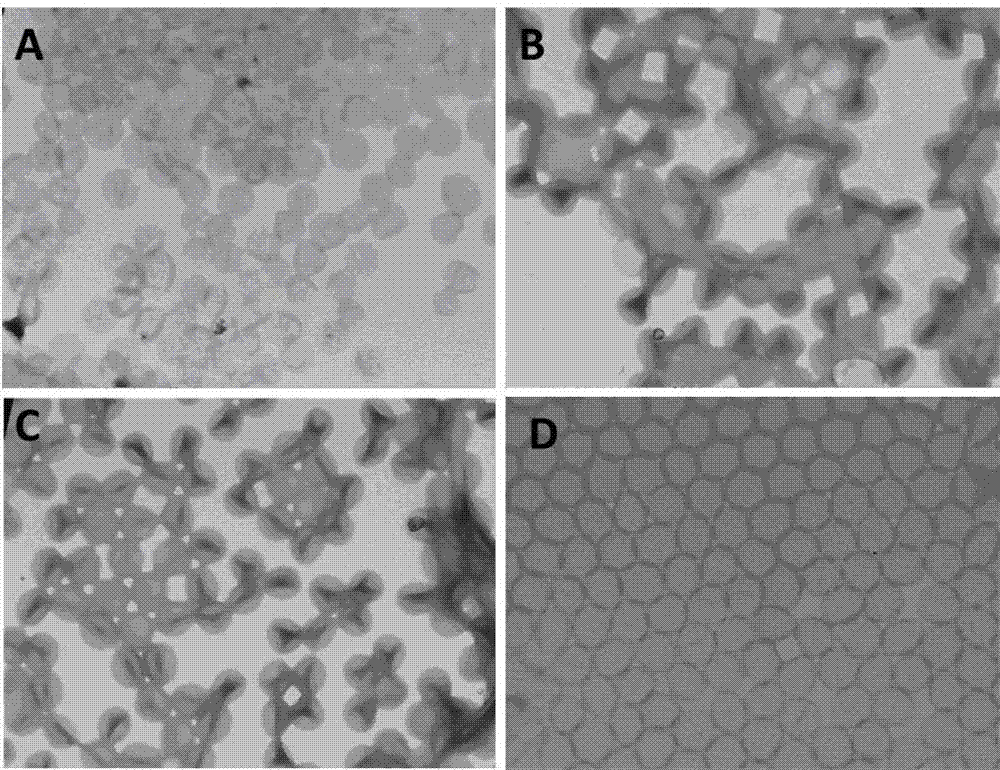

[0027] Example 1: Preparation of PMAA microcapsules with a shell thickness of 25 nm and a crosslinking degree of 40%

[0028] (1) Synthesis of uncrosslinked PMAA nanospheres: 2 g of MAA, 0.04 g of AIBN, and 80 mL of acetonitrile were added to a 100 mL single-necked bottle and heated to 100 o C, reflux reaction for 2 h. The solvent and unreacted monomers were removed by centrifugation, washed three times with acetonitrile, and dried in a vacuum oven for 24 h.

[0029] (2) Synthesis of PMAA nanospheres with core-shell structure: Take 100 mg PMAA nanospheres, 200 mg MAA monomer, 80 mg BACy cross-linking agent, 10 mg AIBN initiator, 40 mL acetonitrile, heat to 100 o C, reflux reaction for 2 h. Unreacted monomers were removed by centrifugation, washed three times with acetonitrile, and dried in a vacuum oven for 24 h.

[0030] (3) Dissolve the prepared PMAA nanospheres with core-shell structure in 50 mL ethanol solution and heat to 50 oC , etch for 3 h. Centrifuged, washed...

Embodiment 2

[0031] Example 2: Preparation of PAA microcapsules with a shell thickness of 15 nm and a crosslinking degree of 30%

[0032] (1) Synthesis of uncrosslinked PAA nanospheres: AA 1 g, AMBN 0.02 g, and 80 mL of acetonitrile were added to a 100 mL single-necked bottle and heated to 100 o C, reflux reaction for 2 h. The solvent and unreacted monomers were removed by centrifugation, washed three times with acetonitrile, and dried in a vacuum oven for 24 h.

[0033] (2) Synthesis of PAA nanospheres with core-shell structure: take 50 mg of PAA nanospheres, 200 mg of AA monomer, 60 mg of BACy cross-linking agent, 10 mg of AMBN initiator, 40 mL of acetonitrile, and heat to 120 o C, reflux reaction for 1 h. Unreacted monomers were removed by centrifugation, washed three times with acetonitrile, and dried in a vacuum oven for 24 h.

[0034] (3) Dissolve the prepared PAA nanospheres with core-shell structure in 50 mL water and heat to 50 oC , etch for 3 h. Centrifuged, washed 3 time...

Embodiment 3

[0035] Example 3: Preparation of PHEMA microcapsules with a shell thickness of 10 nm and a crosslinking degree of 20%

[0036] (1) Synthesis of uncrosslinked PHEMA nanospheres: HEMA 0.5 g, AMBN 0.02 g, and 50 mL of acetonitrile were added to a 100 mL single-necked bottle and heated to 90 o C, reflux reaction for 2 h. The solvent and unreacted monomers were removed by centrifugation, washed three times with acetonitrile, and dried in a vacuum oven for 24 h.

[0037] (2) Synthesis of PHEMA nanospheres with core-shell structure: Take 50 mg PHEMA nanospheres, 200 mg HEMA monomer, 40 mg BACy crosslinker, 10 mg AIBN initiator, 40 mL acetonitrile, heat to 90 o C, reflux reaction for 1 h. Unreacted monomers were removed by centrifugation, washed three times with acetonitrile, and dried in a vacuum oven for 24 h.

[0038] (3) Dissolve the prepared PHEMA nanospheres with core-shell structure in 50 mL of water and ethanol, and heat to 50 oC , etch for 3 h. Centrifuged, washed 3 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com