Automatic temperature control device for shoe-drying panel

A technology for panels and baking shoes, applied in household cleaning devices, non-electric variable control, temperature control, etc., can solve the problems of nowhere to bake wet shoes, not being able to bake, and discounts on the baking effect of wet shoes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

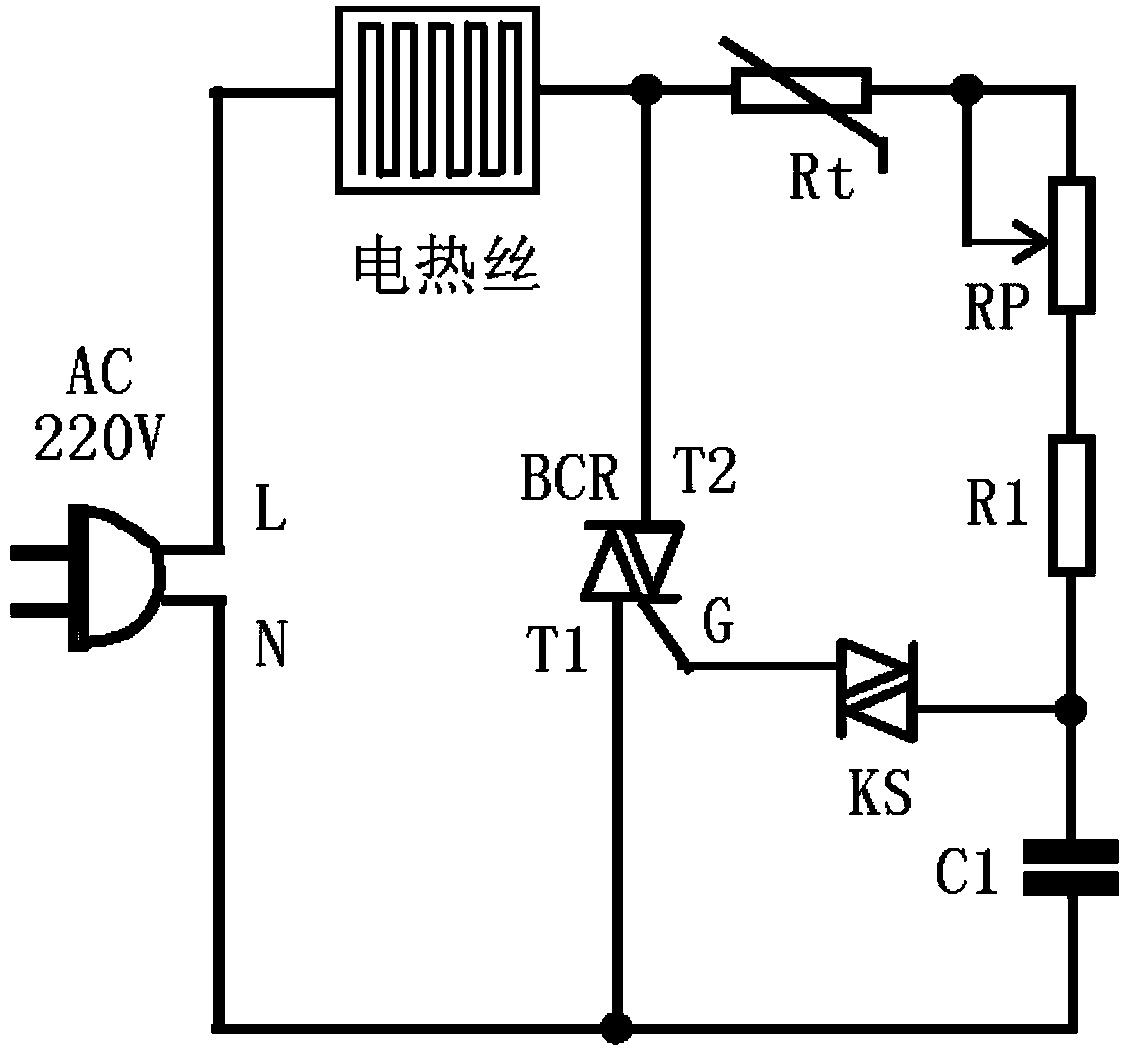

[0012] According to attached figure 1 The working principle diagram and description of the circuit of the automatic temperature control device for the baking shoe panel shown, and the connection relationship between the components in each part of the circuit described in the summary of the invention, as well as the technical parameter requirements and requirements of the components described in the implementation mode The main points of making the circuit can be implemented to realize the present invention, and the related technologies of the present invention will be further described below in conjunction with the embodiments.

[0013] Technical parameters and selection requirements of components

[0014] BCR is a bidirectional thyristor, and the selected model is 3CTSI;

[0015] KS is a bidirectional trigger diode, the selected model is 2CTS, or BCR3AM;

[0016] The resistance of the thermistor Rt is 5.1KΩ, and the thermistor Rt is required to use a positive temperature co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com