Method and device for detecting malfunctions of various exhaust gas probes during operation of an internal combustion engine

A technology of exhaust gas probe and internal combustion engine, applied in electrical control, mechanical equipment, engine control, etc., can solve the problems of slow response characteristics, aggravated harmful substance emission, change of invalid time, etc., and achieve the effect of reliable diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

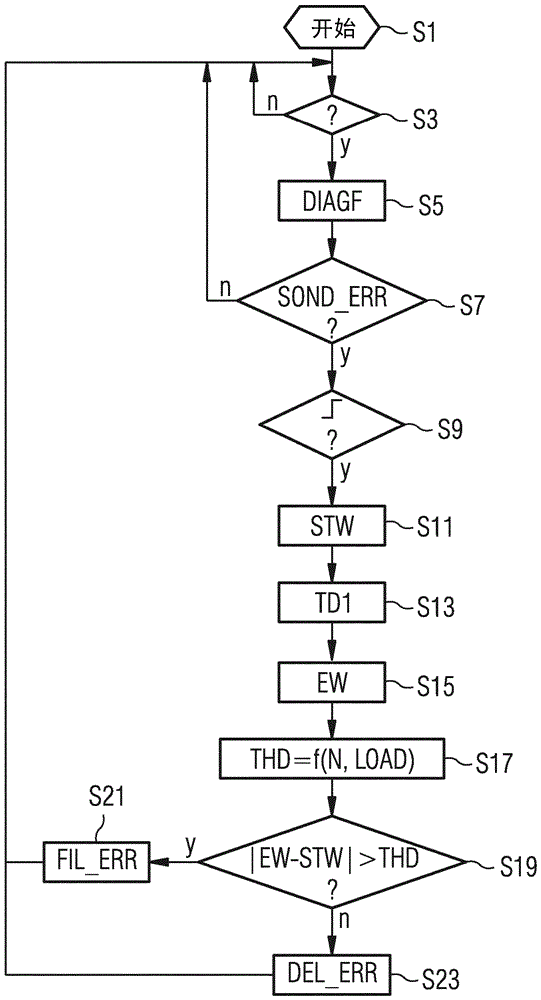

Method used

Image

Examples

Embodiment Construction

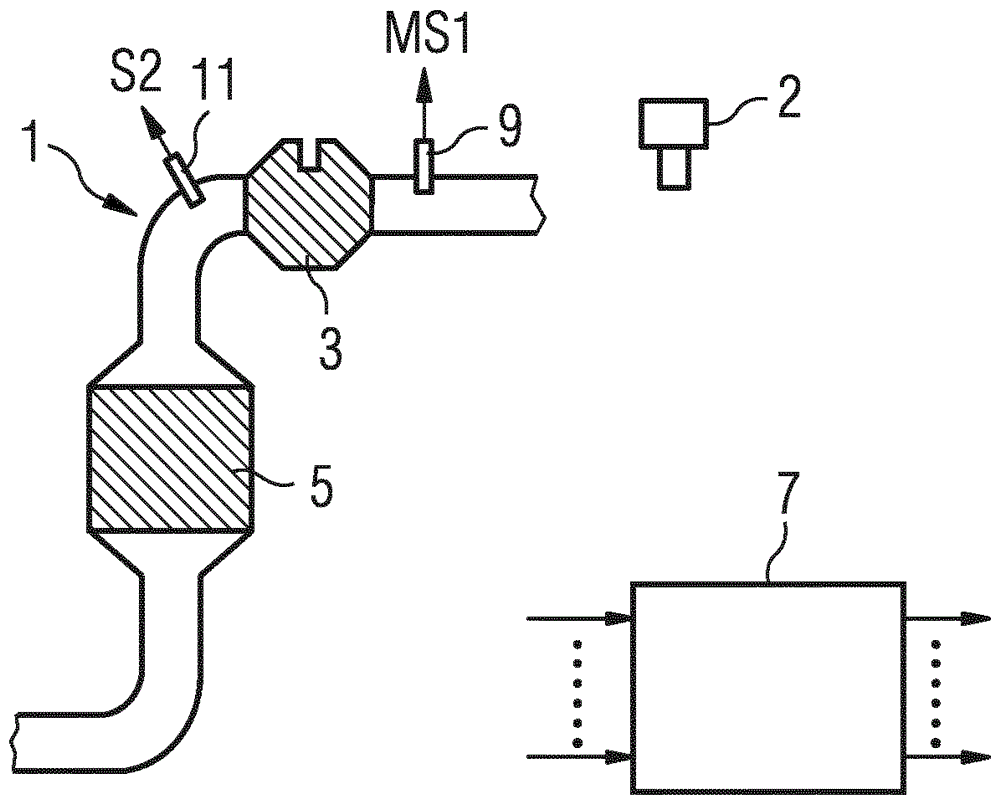

[0020] The internal combustion engine includes the intake port, the engine block, the cylinder head and the exhaust port 1 ( figure 1 ). The intake duct preferably includes a throttle valve and also includes a collector and an intake duct which projects into the engine block towards the cylinders via the inlet duct. Furthermore, the engine block includes a crankshaft, which is coupled with the pistons of the cylinders via connecting rods.

[0021] The cylinder head includes a gas distribution train with gas inlet valves and gas outlet valves. The cylinder head also includes injection valves 2 and preferably spark plugs. Alternatively, injection valve 2 can also be arranged on the intake manifold.

[0022] An exhaust gas catalytic converter, preferably designed as a three-way catalytic converter, is arranged on the exhaust tract 1 . In addition, a further exhaust gas catalytic converter 5 , which is designed as a NOx catalytic converter, is optionally arranged on the exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com