Battery-grade ferric phosphate and preparation method

An iron phosphate, battery-grade technology, applied in phosphates, battery electrodes, phosphorus oxyacids, etc., can solve the problems of heat removal, increased energy consumption, low bulk density, etc., to improve product consistency and determine ingredients Reliable, high bulk density results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

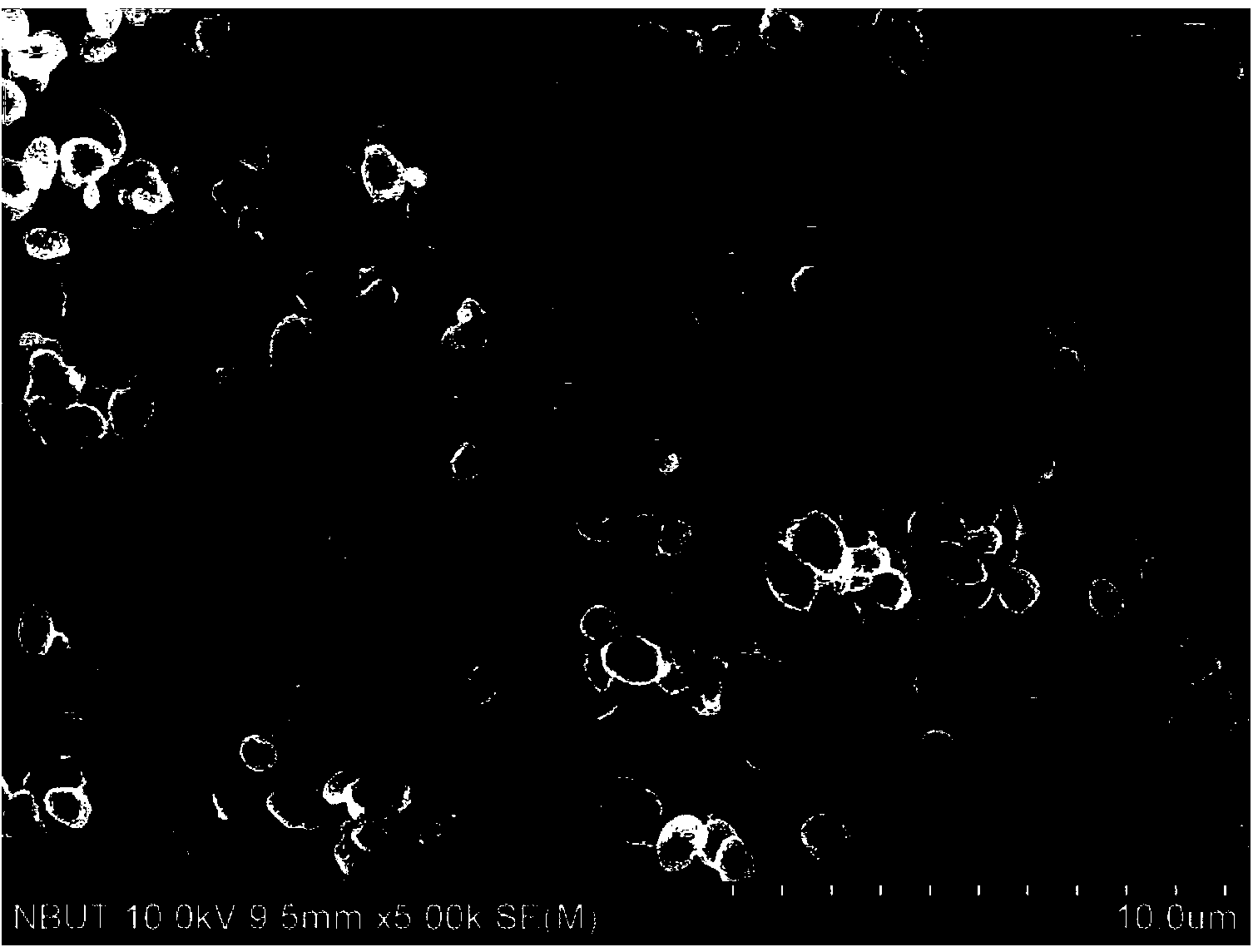

[0060] The preparation method of the battery-grade iron phosphate is to use ferric nitrate as an iron source, and phosphoric acid or ammonium dihydrogen phosphate or diammonium hydrogen phosphate or ammonium phosphate as a phosphorus source; prepare a mixed aqueous solution of an iron source and a phosphorus source; Ammonia solution is added to the aqueous solution of the mixture of iron source and phosphorus source as a pH adjuster, stirred and reacted to form a crystalline complex containing ammonium, hydroxide and crystal water, and then solid-liquid separation and drying to obtain NH 4 Fe 2 (OH)(PO 4 ) 2 2H 2 O powder, in which the molar ratio of iron and phosphorus is 0.99-1.01:1, the powder is composed of monodisperse olive-shaped particles with regular appearance, and the tap density is as high as 1.2-1.3g / cm 3 ; The powder is roasted in the air atmosphere to decompose and remove ammonium, hydroxide and crystal water to obtain battery-grade anhydrous iron phosphate F...

Embodiment 1

[0070] Prepare ferric nitrate and phosphoric acid mixed aqueous solution, wherein ferric nitrate concentration is 2.0 mol / liter, phosphoric acid concentration is 2.0 mol / liter, the mol ratio of phosphorus and iron is 1: 1;

[0071] Preparation concentration is the ammonia solution of 10.0 mol / liter as pH regulator;

[0072] Add 2 liters of deionized water to the reaction kettle with a volume of 7 liters, stir vigorously, and pass constant temperature water into the jacket of the reaction kettle, and control the water temperature in the reaction kettle to 95°C;

[0073] Continuously input the mixed aqueous solution of ferric nitrate and phosphoric acid and ammonia solution into the reactor respectively with a pump, control the flow rate of the mixed aqueous solution of ferric nitrate and phosphoric acid to 20 ml / min, adjust the flow rate of ammonia solution, and control the pH value of the reaction solution in the reactor 1.60±0.05;

[0074] Through a constant temperature wate...

Embodiment 2

[0081] Prepare ferric nitrate and ammonium phosphate mixed aqueous solution, wherein ferric nitrate concentration is 0.2 mol / liter, ammonium phosphate concentration is 0.2 mol / liter, the mol ratio of phosphorus and iron is 1: 1;

[0082] Preparation concentration is the ammonia solution of 0.5 mol / liter as pH regulator;

[0083] Add 2 liters of deionized water to the reactor with a volume of 7 liters, stir vigorously, and pass constant temperature water into the jacket of the reactor, and control the water temperature in the reactor to 60°C;

[0084] The ferric nitrate and ammonium phosphate mixed aqueous solution and the ammonia solution are respectively continuously input into the reactor with a pump, the flow of the ferric nitrate and ammonium phosphate mixed aqueous solution is controlled to be 20 ml / min, the flow of the ammonia solution is adjusted, and the reaction liquid in the reactor is controlled. The pH value is 5.50±0.05;

[0085] Through a constant temperature wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com